| Availability: | |

|---|---|

| Quantity: | |

MYDN303

BOEEP

MYDN

Product Description

Compared with the traditional volute screw press dewatering machine, BOEEP inclined screw sludge thickener is also advanced in the low operating & maintenance cost, dewatering performance, smell protection, low noise, automatic control, etc. The sludge with very low concentration of 2500mg/L-20000mg/L from the secondary sedimentation tank can be condensed rapidly and continuously, and the sludge concentration can be adjusted between 90% and 96% stably after being condensed and separated. In addition, the device has many advantages such as no need concentrated tank, small footprint, less cost. Further more, it can effectively reduce the release of the odor & phosphorus caused by sludge concentrated tank, simplify the following treatment process, greatly increase the capacity of sludge dewatering and deep dehydration equipment.

Main Structure & Working Principle

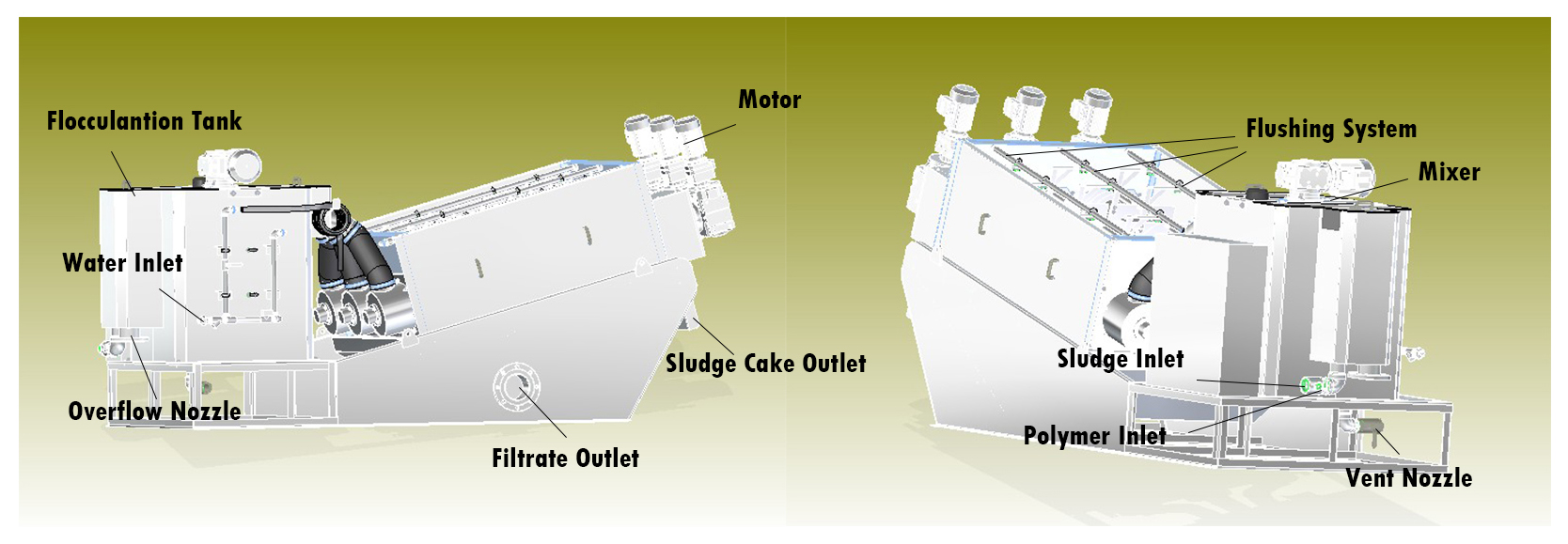

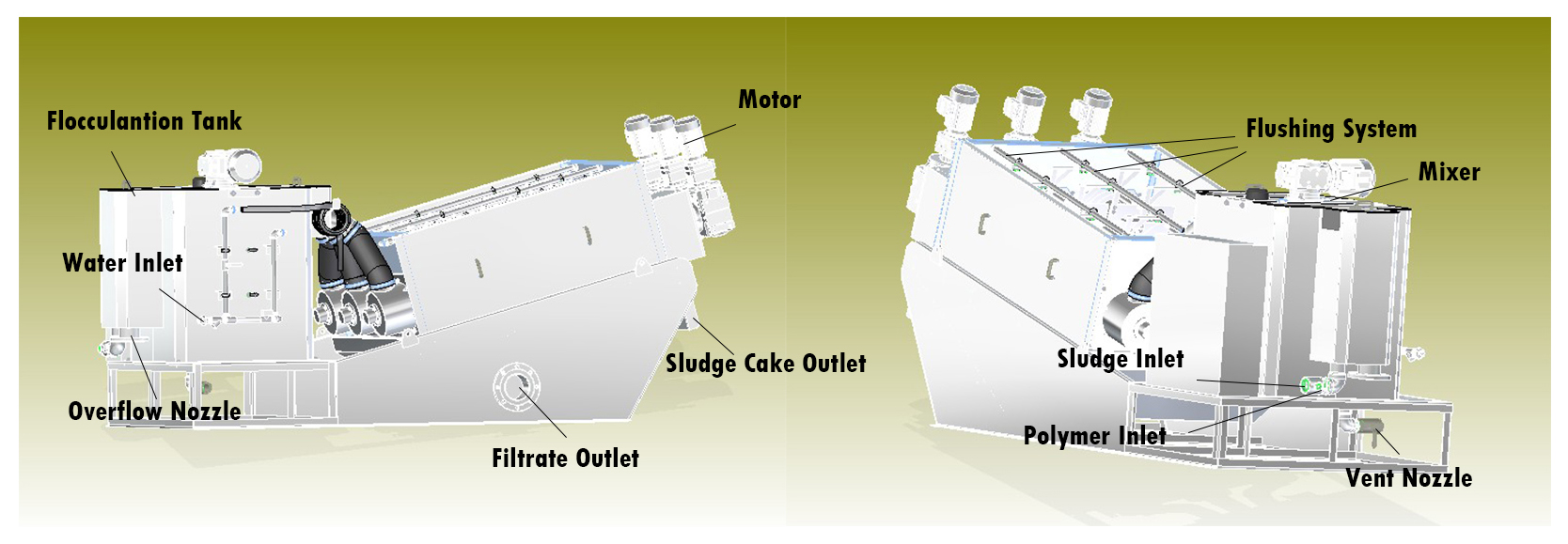

BOEEP inclined screw sludge thickener is composed of screw body, driving device, filtrate receiver, mixing system and frame. There are 3 parts which constitutes the main body of volute screw press thickener. They are fixed ring, moveable ring and the screw shaft which runs through the main body.

BOEEP inclined screw sludge thickener mainly consists of concentrating body, driving device, filtered water tank, mixing system and frame, etc. During operating, the sludge is pumped into the mixing tank by sludge pump, meanwhile, dosing pump feeds the mixing tank with prepared polymer quantificationlly. The sludge is mixed completely with the polymer by the stirring of motor in the mixing system, then flocs will be produced. When the liquid reach the level of liquid level sensor, the screw body will get into operation, in which the sludge is being pressed. The thickened sludge will be discharged at the outlet gradually and the filtered water will come out between the fixed ring and moving ring at the same time.

All in all, inclined screw sludge thickener adopts the principle of screw extruding to thicken the sludge through the high pressure generated by the screw distance changes and small gap between the mobile ring & fixed ring.

Application

1-Solid and liquid separation in the municipla & industrial wastewater treatment system.

2-Sludge dewatering in the municipal & industrial wastewater treatment system.

3-Instead of condensed tank, work as the pre-treat device of the sludge dewatering system.

4-It is the pre-treat device of sludge deep dewatering, also as the auxiliary equipment of high pressure plate and frame filter press, membrane filter presser.

5-Other wastewater treatment applications in the municipal & industrial wastewater treatment system.

Adavantages

| Large sludge concentration range, applied water content of sludge: 98%-99.8%. | The water content after thickened is 90%-96%, which can be adjusted stability |

| High concentration efficiency, small footprint | No need filter cloth, high pressure back water rinsing, self-cleaning, clog free |

| Low rotating speed, low noise, low power consumption, compact design. | Enclosed working, odor emission is controled |

| Less wearing parts, easy to operate & maintain | Fully-automatic control, low labor need |

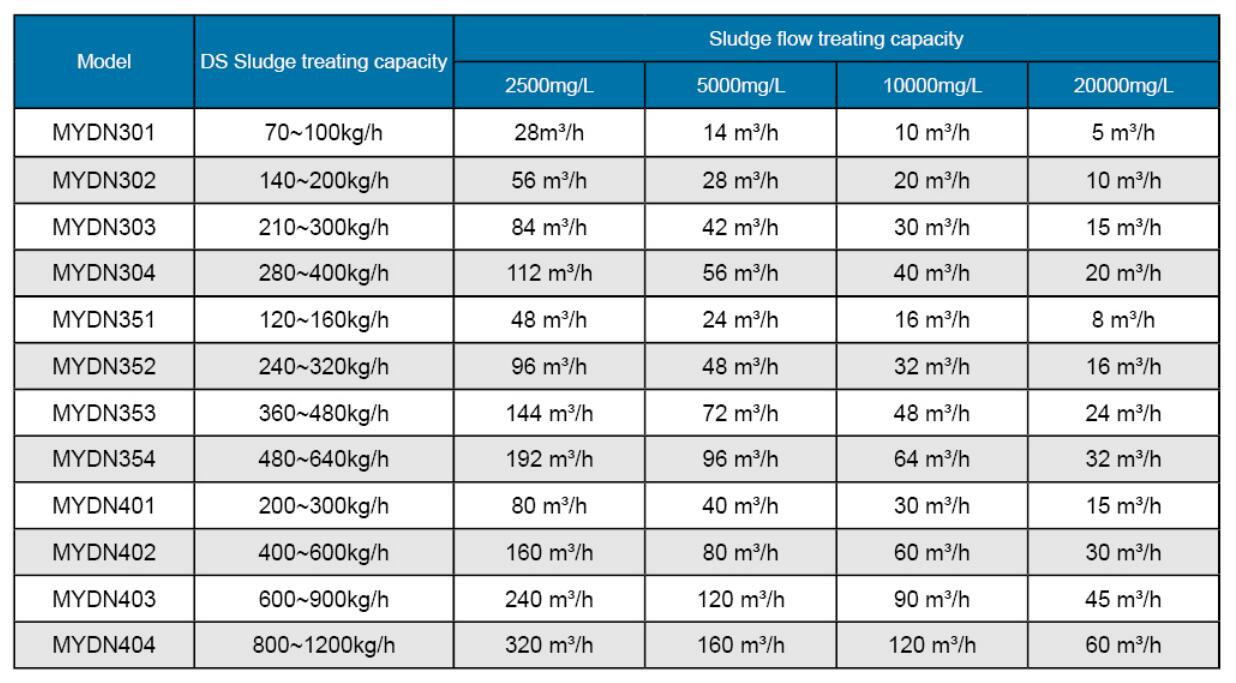

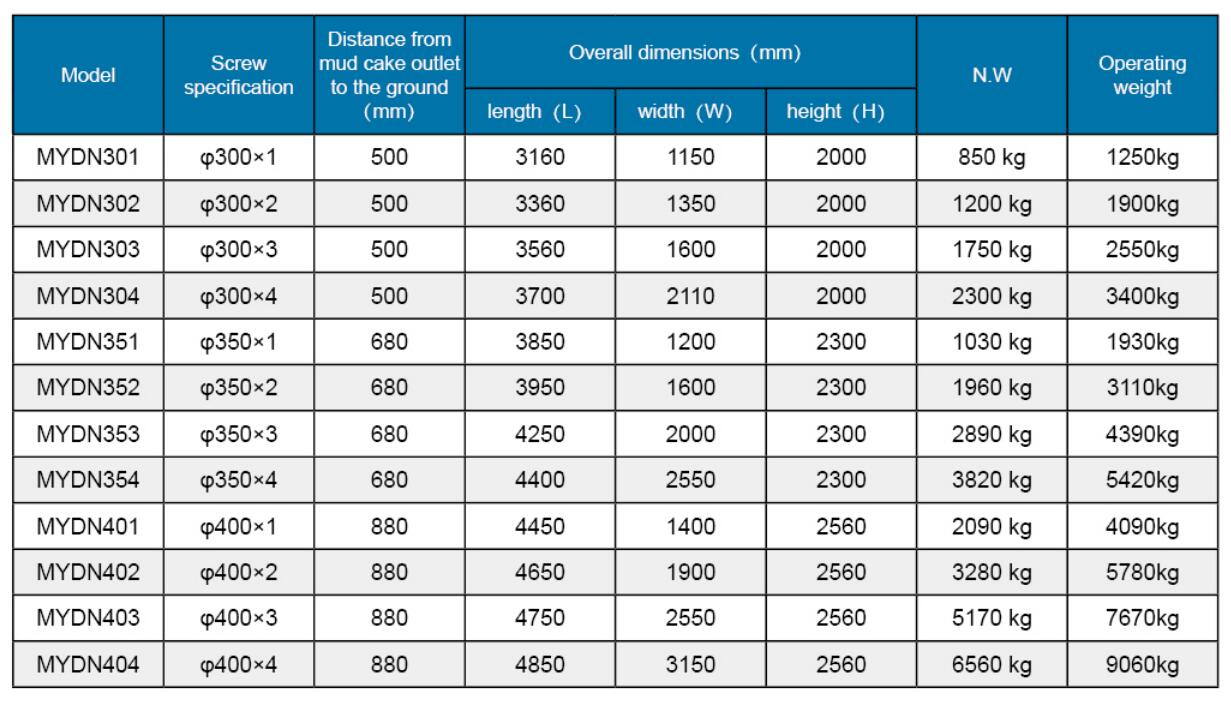

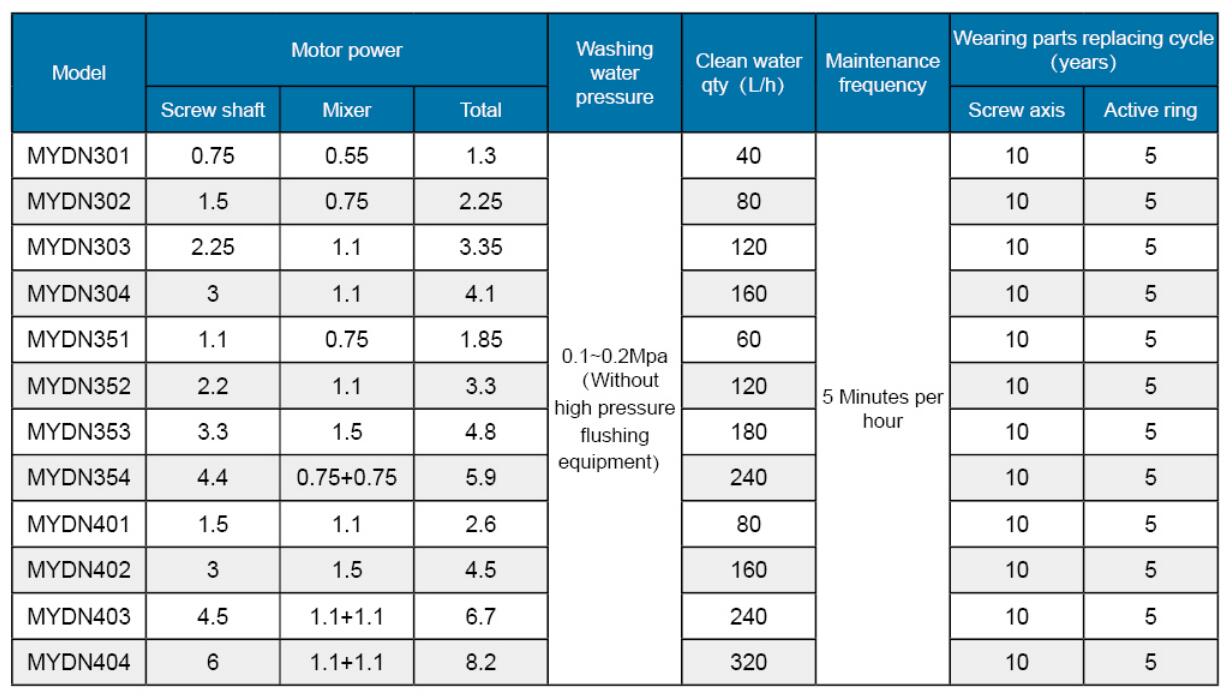

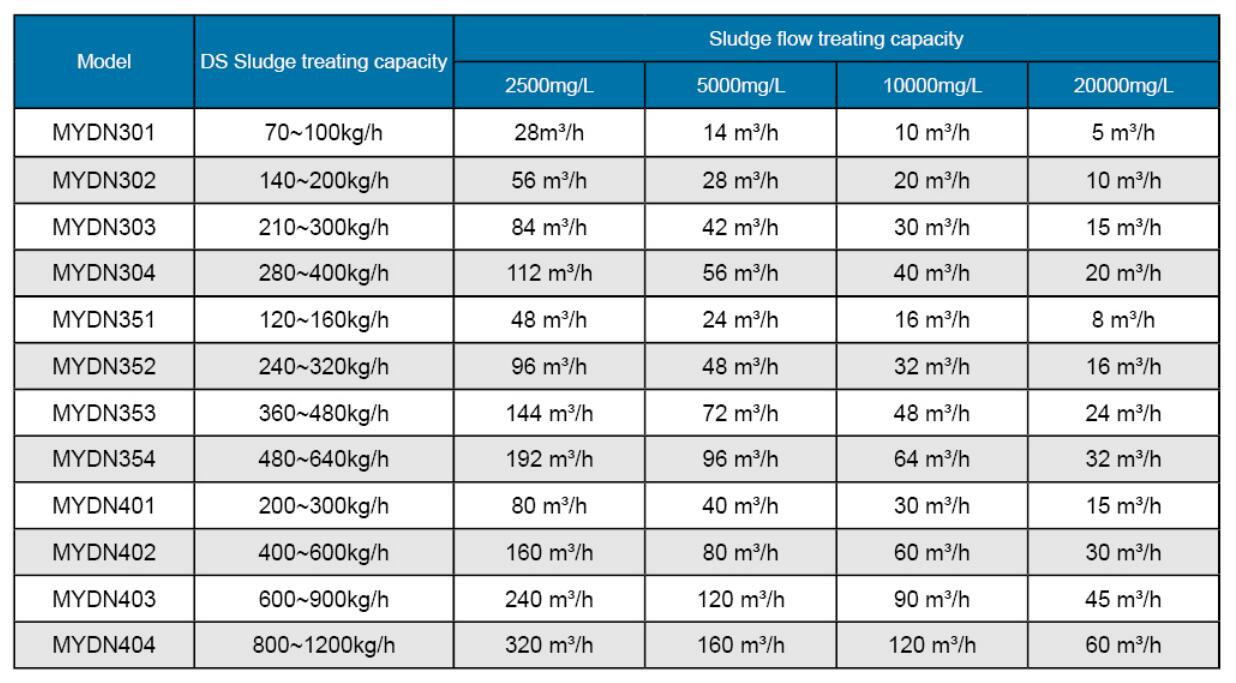

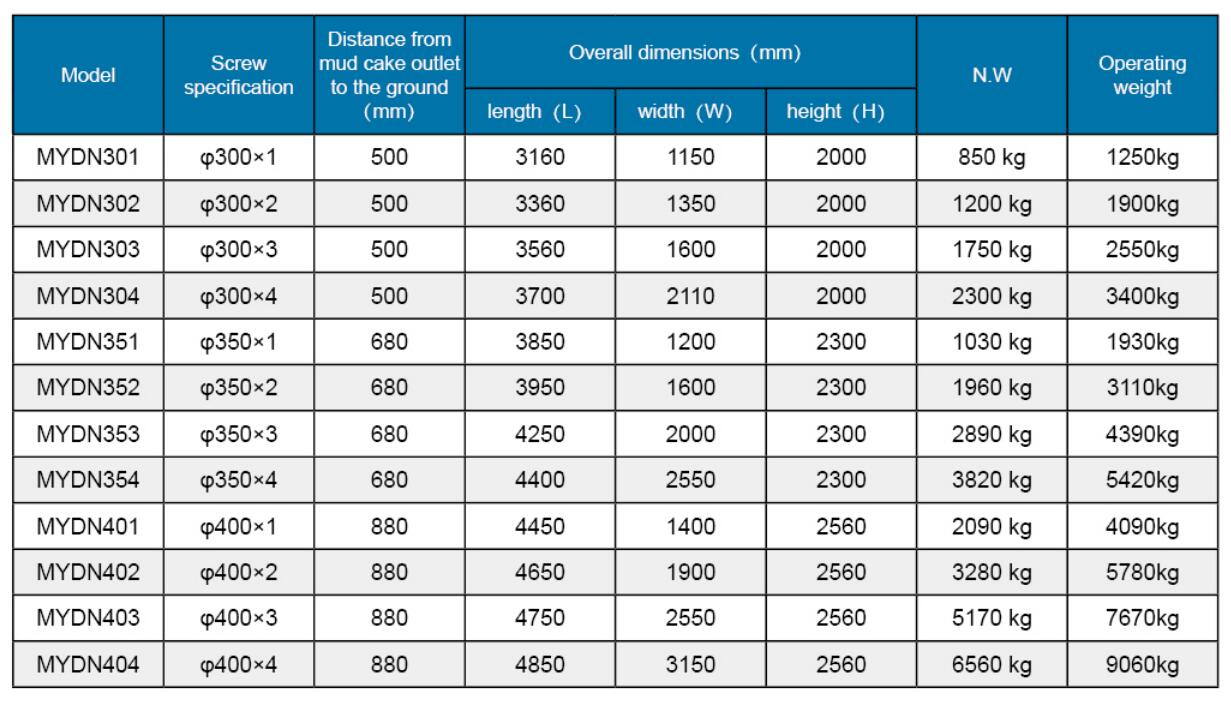

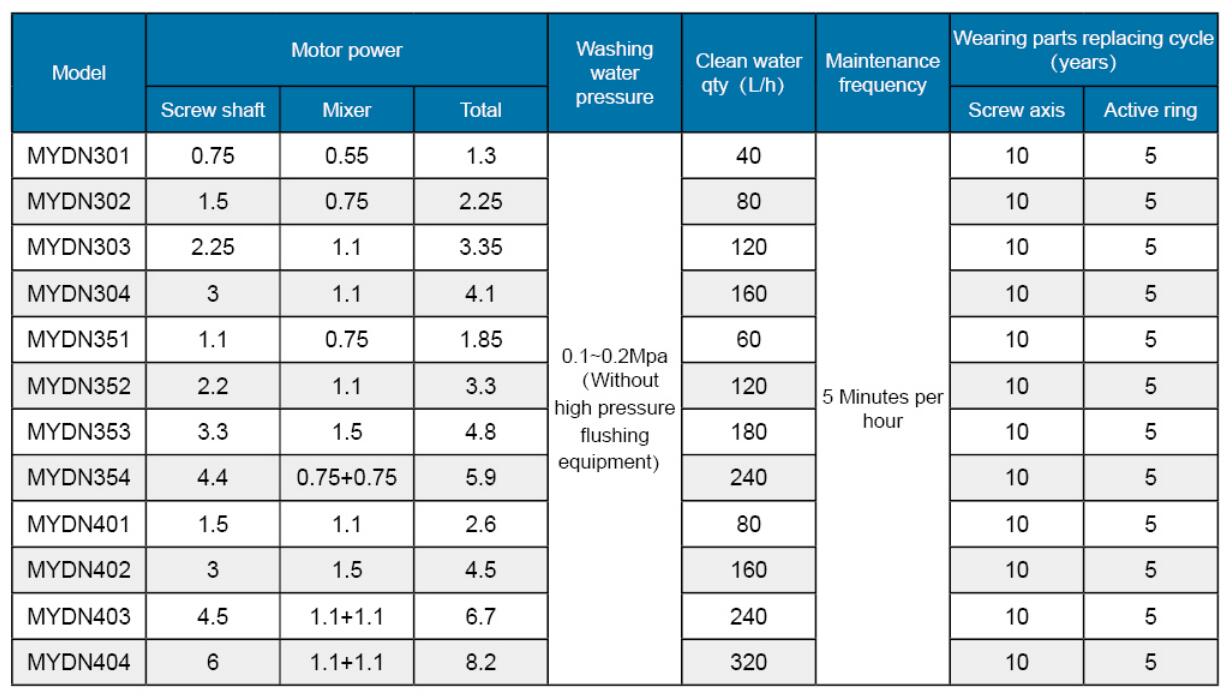

Technical Parameters

| Parameter | |

| Type:MYDN303 | Dimension:L3535×W1620×H1720(mm) |

| Inlet sludge solid concentration:2500~20000mg/L | Capacity:210-300kgds/h |

| Power:3.35kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Outlet sludge moisture content:90-95% |

| Polymer feeding rate:DS 0.2~1% | Flush water:120L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:1750kg |

| Screw body | Flocculation mixing tank |

| Diameter × Length:Φ300×2110(mm) | Dimension:L850×W850×H1000(mm) |

| Quantity:3pcs | Volume:about 650L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:0.75×3kW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls thickening body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Technical Specification

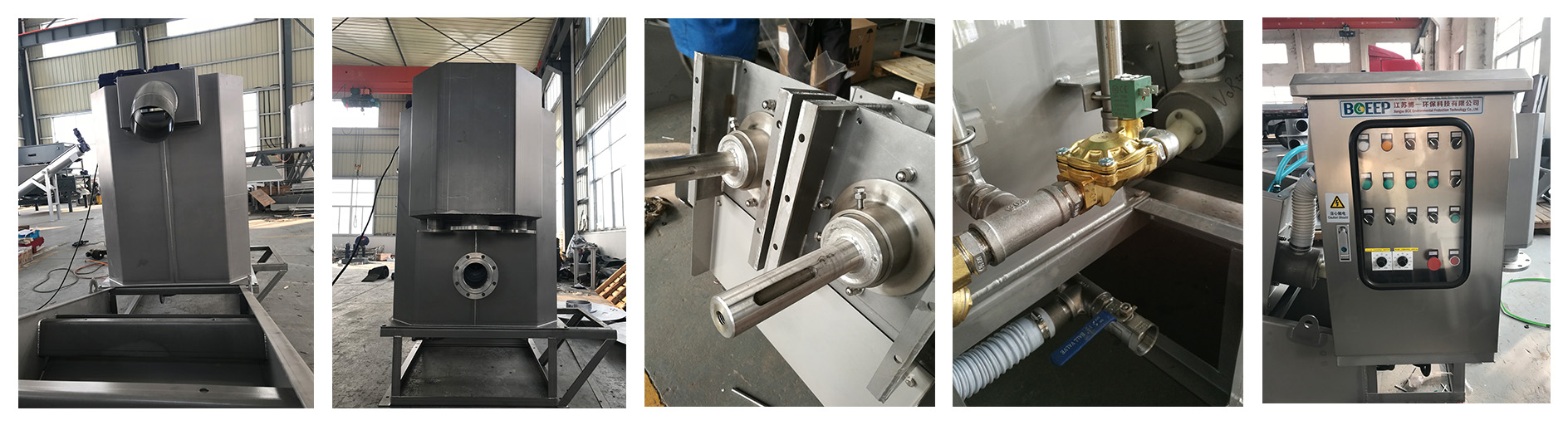

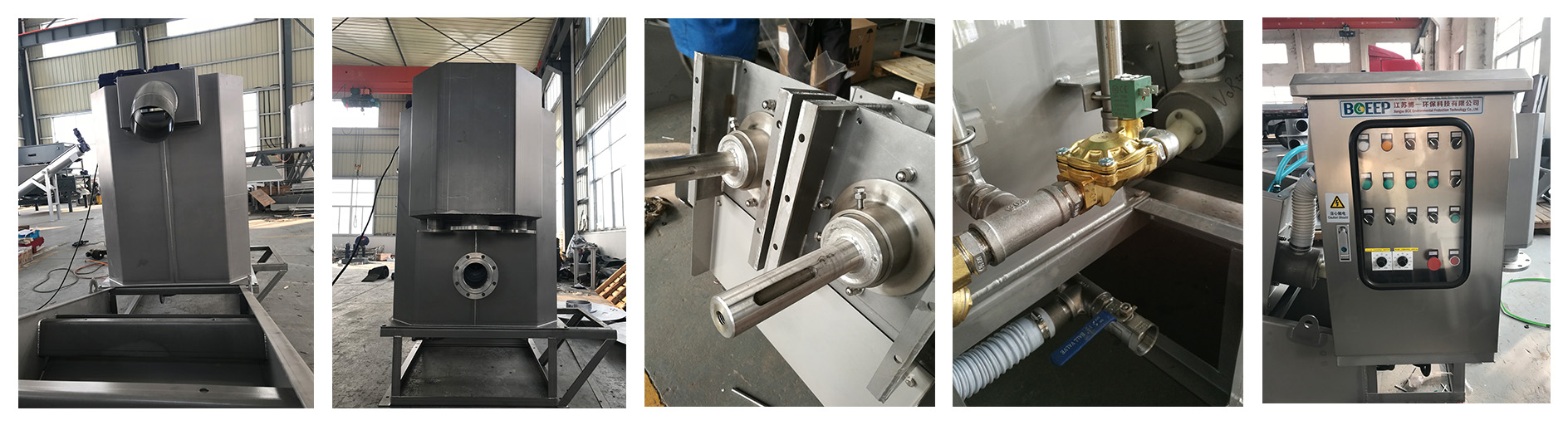

Product Details

Packing Site

Product Description

Compared with the traditional volute screw press dewatering machine, BOEEP inclined screw sludge thickener is also advanced in the low operating & maintenance cost, dewatering performance, smell protection, low noise, automatic control, etc. The sludge with very low concentration of 2500mg/L-20000mg/L from the secondary sedimentation tank can be condensed rapidly and continuously, and the sludge concentration can be adjusted between 90% and 96% stably after being condensed and separated. In addition, the device has many advantages such as no need concentrated tank, small footprint, less cost. Further more, it can effectively reduce the release of the odor & phosphorus caused by sludge concentrated tank, simplify the following treatment process, greatly increase the capacity of sludge dewatering and deep dehydration equipment.

Main Structure & Working Principle

BOEEP inclined screw sludge thickener is composed of screw body, driving device, filtrate receiver, mixing system and frame. There are 3 parts which constitutes the main body of volute screw press thickener. They are fixed ring, moveable ring and the screw shaft which runs through the main body.

BOEEP inclined screw sludge thickener mainly consists of concentrating body, driving device, filtered water tank, mixing system and frame, etc. During operating, the sludge is pumped into the mixing tank by sludge pump, meanwhile, dosing pump feeds the mixing tank with prepared polymer quantificationlly. The sludge is mixed completely with the polymer by the stirring of motor in the mixing system, then flocs will be produced. When the liquid reach the level of liquid level sensor, the screw body will get into operation, in which the sludge is being pressed. The thickened sludge will be discharged at the outlet gradually and the filtered water will come out between the fixed ring and moving ring at the same time.

All in all, inclined screw sludge thickener adopts the principle of screw extruding to thicken the sludge through the high pressure generated by the screw distance changes and small gap between the mobile ring & fixed ring.

Application

1-Solid and liquid separation in the municipla & industrial wastewater treatment system.

2-Sludge dewatering in the municipal & industrial wastewater treatment system.

3-Instead of condensed tank, work as the pre-treat device of the sludge dewatering system.

4-It is the pre-treat device of sludge deep dewatering, also as the auxiliary equipment of high pressure plate and frame filter press, membrane filter presser.

5-Other wastewater treatment applications in the municipal & industrial wastewater treatment system.

Adavantages

| Large sludge concentration range, applied water content of sludge: 98%-99.8%. | The water content after thickened is 90%-96%, which can be adjusted stability |

| High concentration efficiency, small footprint | No need filter cloth, high pressure back water rinsing, self-cleaning, clog free |

| Low rotating speed, low noise, low power consumption, compact design. | Enclosed working, odor emission is controled |

| Less wearing parts, easy to operate & maintain | Fully-automatic control, low labor need |

Technical Parameters

| Parameter | |

| Type:MYDN303 | Dimension:L3535×W1620×H1720(mm) |

| Inlet sludge solid concentration:2500~20000mg/L | Capacity:210-300kgds/h |

| Power:3.35kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Outlet sludge moisture content:90-95% |

| Polymer feeding rate:DS 0.2~1% | Flush water:120L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:1750kg |

| Screw body | Flocculation mixing tank |

| Diameter × Length:Φ300×2110(mm) | Dimension:L850×W850×H1000(mm) |

| Quantity:3pcs | Volume:about 650L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:0.75×3kW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls thickening body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Technical Specification

Product Details

Packing Site