| Availability: | |

|---|---|

| Quantity: | |

MYDL353

BOEEP

MYDL

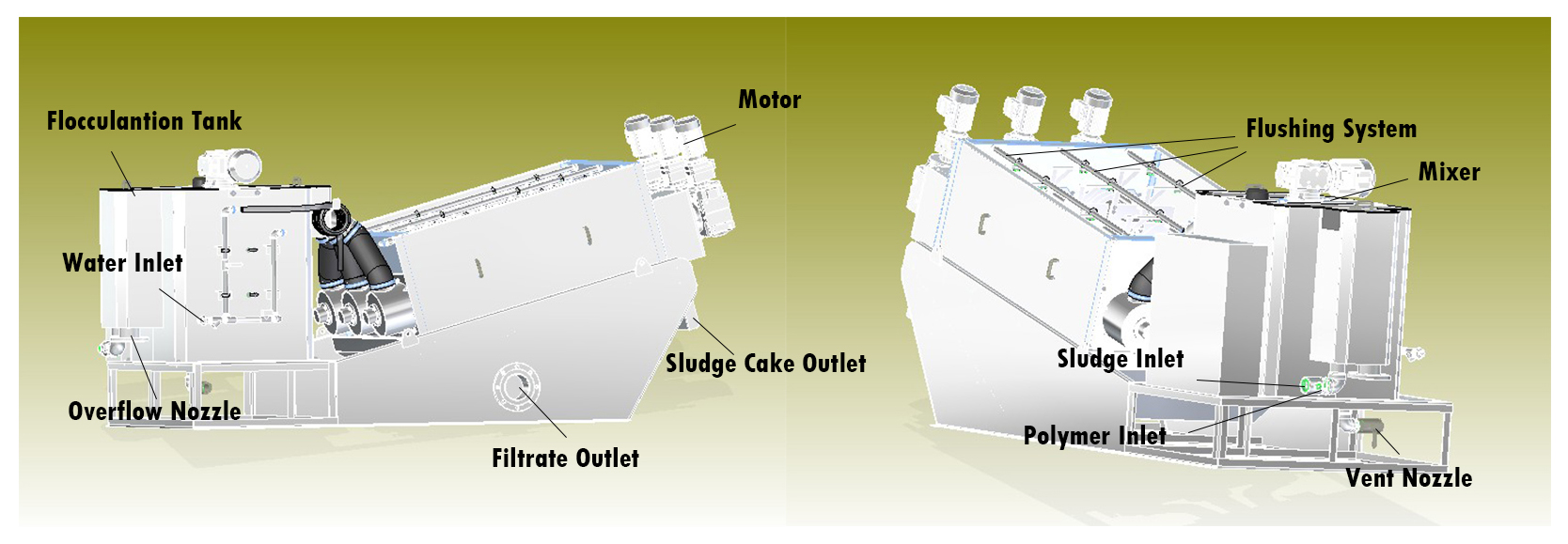

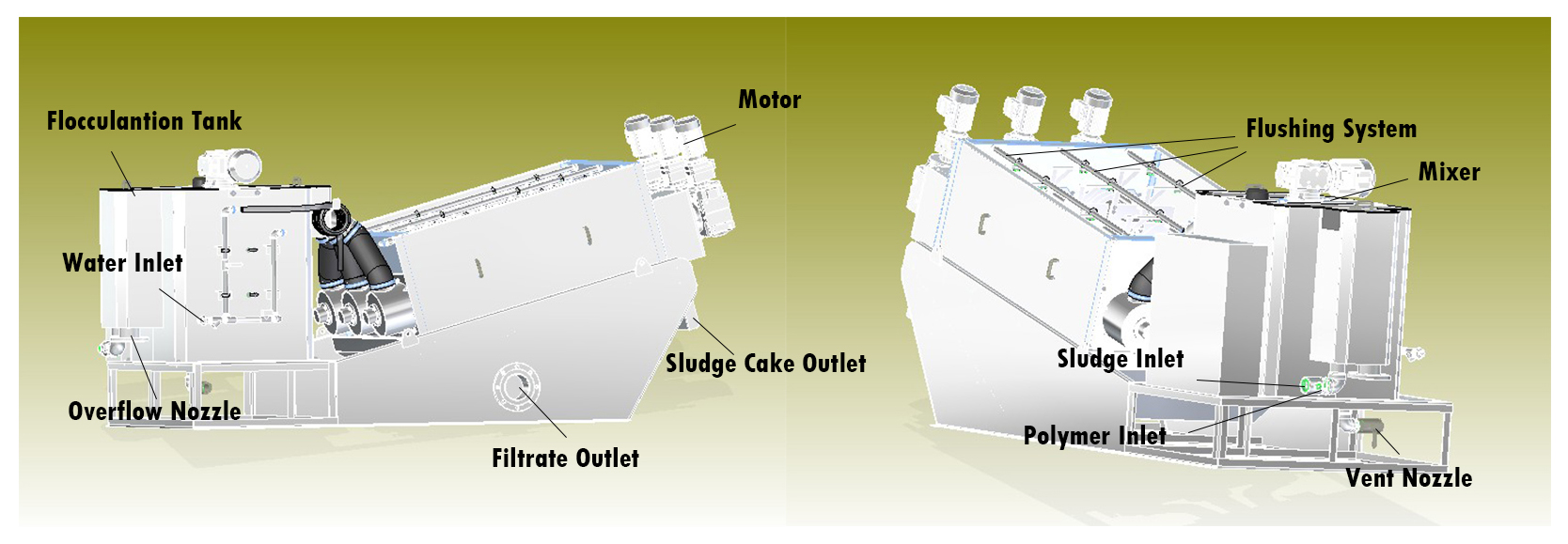

Structure of Screw Filter Press

BOEEP screw filter press sludge dehydrator is composed of screw body, driving device, filtrate receiver, mixing system and frame. When the dewatering machine operates, sludge will be transported to the mixing tank by sludge feed pump, at the same time, the solid polymer has been added to the mixing tank quantitatively by the polymer feed pump. Mixing motor drives the whole mixing system to make the sludge and polymer fully mixed and then flocs will be produced. When the liquid level arrives at the superior level of the liquid level sensor, the liquid level sensor gets the signal to make the motor of screw body operates, then begins to press the sludge which has flows into the screw body. Sludge will be transported to the outlet step by step by the effect of screw shaft; filtrate will flow out by the space of fixed rings and moveable rings.

Working Principle of Screw Filter Press

The main body of screw filter press is made of multiple fixed annular plates and moveable annular plates with the screw shaft running through it. The front part is concentrating section and the ending part is dewatering section. It can concentrate and dewater sludge in one chamber and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

Sludge will be transported to the dewatering part after being concentrated in the thickenning section. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance with the block of the back platen. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Flow Chart of Screw Filter Press

Application of Screw Filter Press

| Landfill leachate/refuse leachate/percolated fluid | Animal husbandry/livestock industry/livestock breeding | Refuse processing plant/garbage proposal |

| Biotechnology/bioengineering/biological engineering/bioengineering | Anaerobic digested sludge/aerobic sludge | Tobacco industry wastewater treatment |

| Brewery/wine process wastewater | Hospital sewage | Machining wastewater |

| Printing and dyeing | Water purification industry | Chemical wastewater |

| Petrochemical industry/oily sludge | Eletroplating industry | Paper making |

| Animal slaughter/animal butcher | Recycled water/reclaimed water | Coal chemical industry |

| Cooking wastewater/kitchen waste | Industrial wastewater | Textile |

Features of Screw Filter Press

Automatic & continuous operation.

Cannot be clogged easily.

Low operation cost.

Energy saving.

Good surrounding with no vibration, no noise and little odor.

Easy operation and maintenance.

Compact set of flocculation, thickening and dewatering functions.

Technical Parameters of Screw Filter Press

| Parameter | |

| Type:MYDL353 | Dimension:L4520×W1980×H2130(mm) |

| Solid content:10000~50000mg/L | Capacity:300-360kgds/h |

| Power:4.8kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Output sludge moisture content:75-85% |

| Polymer feeding rate:DS 0.2~1% | Flush water:180L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:3100kg |

| Screw body | Flocculated mix tank |

| Specification × Length:Φ350×2800(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:3 | Volume:About 1400L |

| Material:Plate: SUS304/Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:1.1×3kW | Motor power:1.5kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

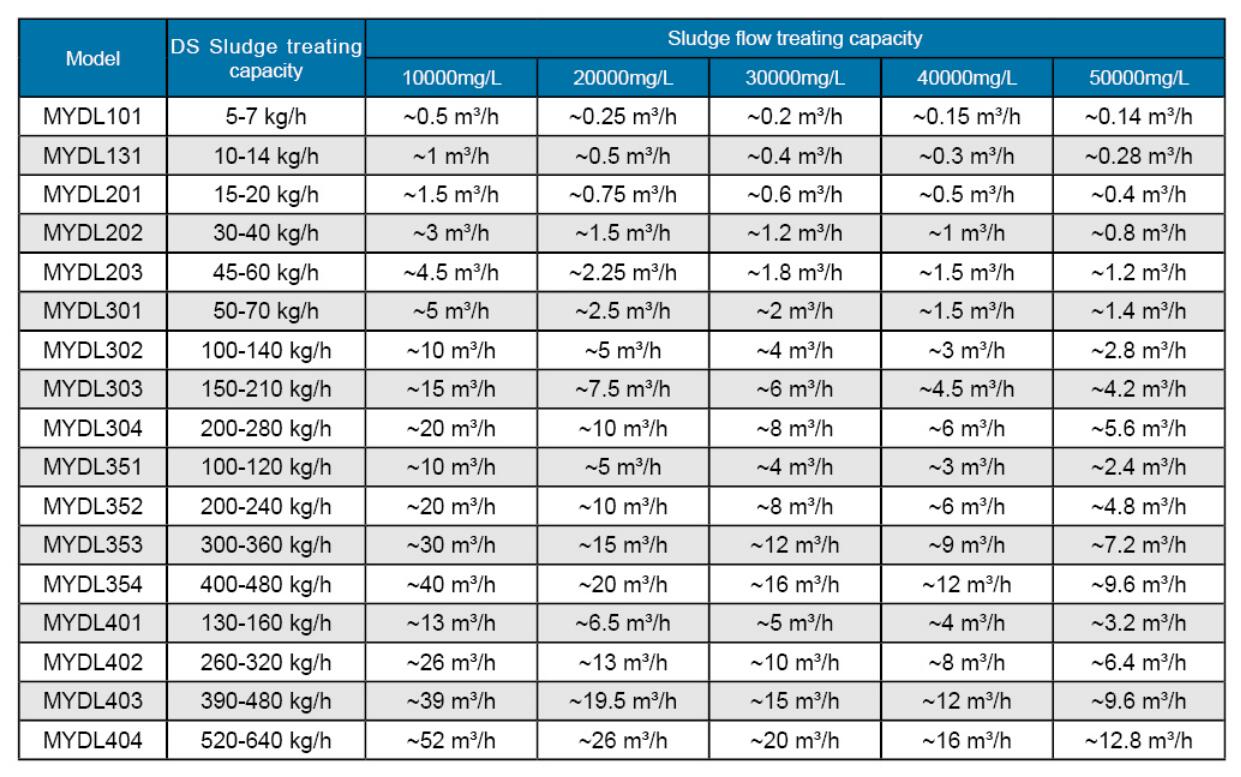

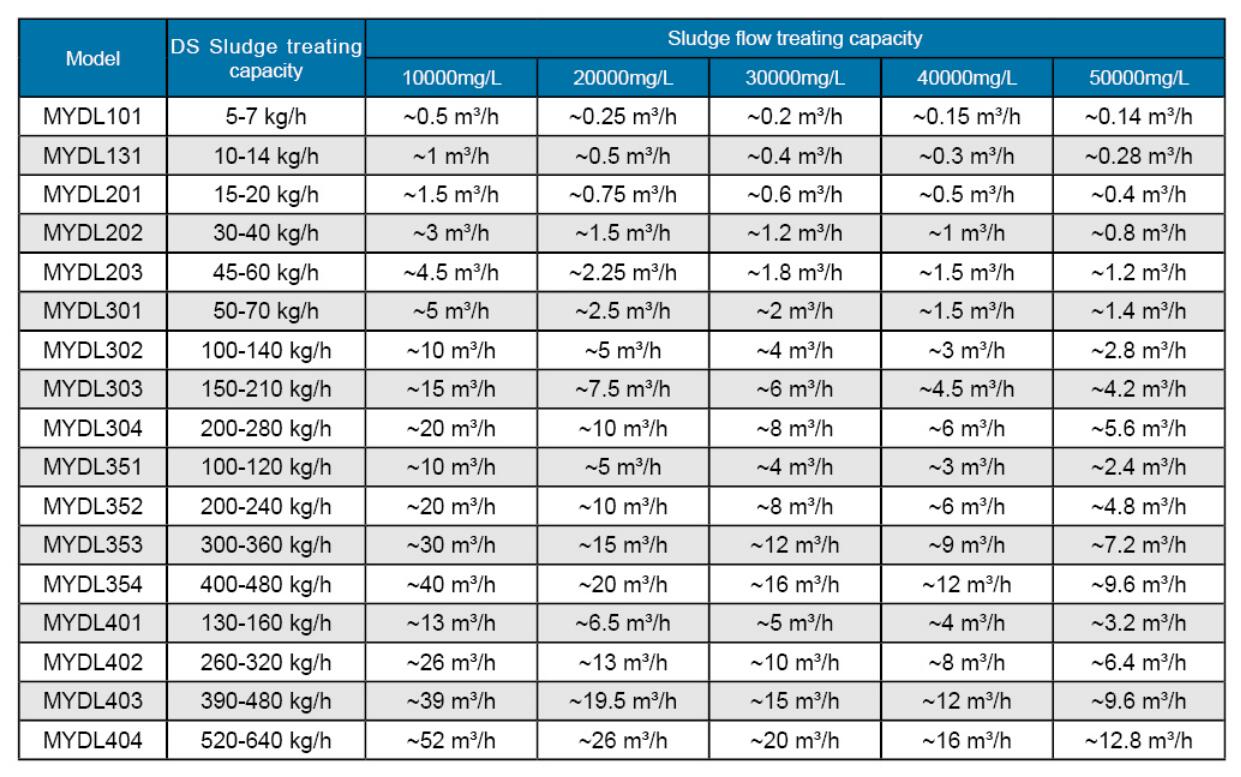

Model Choice of Screw Filter Press

Product Details of Screw Filter Press

Object Site of Screw Filter Press

Paking Site of Screw Filter Press

Structure of Screw Filter Press

BOEEP screw filter press sludge dehydrator is composed of screw body, driving device, filtrate receiver, mixing system and frame. When the dewatering machine operates, sludge will be transported to the mixing tank by sludge feed pump, at the same time, the solid polymer has been added to the mixing tank quantitatively by the polymer feed pump. Mixing motor drives the whole mixing system to make the sludge and polymer fully mixed and then flocs will be produced. When the liquid level arrives at the superior level of the liquid level sensor, the liquid level sensor gets the signal to make the motor of screw body operates, then begins to press the sludge which has flows into the screw body. Sludge will be transported to the outlet step by step by the effect of screw shaft; filtrate will flow out by the space of fixed rings and moveable rings.

Working Principle of Screw Filter Press

The main body of screw filter press is made of multiple fixed annular plates and moveable annular plates with the screw shaft running through it. The front part is concentrating section and the ending part is dewatering section. It can concentrate and dewater sludge in one chamber and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

Sludge will be transported to the dewatering part after being concentrated in the thickenning section. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance with the block of the back platen. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Flow Chart of Screw Filter Press

Application of Screw Filter Press

| Landfill leachate/refuse leachate/percolated fluid | Animal husbandry/livestock industry/livestock breeding | Refuse processing plant/garbage proposal |

| Biotechnology/bioengineering/biological engineering/bioengineering | Anaerobic digested sludge/aerobic sludge | Tobacco industry wastewater treatment |

| Brewery/wine process wastewater | Hospital sewage | Machining wastewater |

| Printing and dyeing | Water purification industry | Chemical wastewater |

| Petrochemical industry/oily sludge | Eletroplating industry | Paper making |

| Animal slaughter/animal butcher | Recycled water/reclaimed water | Coal chemical industry |

| Cooking wastewater/kitchen waste | Industrial wastewater | Textile |

Features of Screw Filter Press

Automatic & continuous operation.

Cannot be clogged easily.

Low operation cost.

Energy saving.

Good surrounding with no vibration, no noise and little odor.

Easy operation and maintenance.

Compact set of flocculation, thickening and dewatering functions.

Technical Parameters of Screw Filter Press

| Parameter | |

| Type:MYDL353 | Dimension:L4520×W1980×H2130(mm) |

| Solid content:10000~50000mg/L | Capacity:300-360kgds/h |

| Power:4.8kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Output sludge moisture content:75-85% |

| Polymer feeding rate:DS 0.2~1% | Flush water:180L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:3100kg |

| Screw body | Flocculated mix tank |

| Specification × Length:Φ350×2800(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:3 | Volume:About 1400L |

| Material:Plate: SUS304/Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:1.1×3kW | Motor power:1.5kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Model Choice of Screw Filter Press

Product Details of Screw Filter Press

Object Site of Screw Filter Press

Paking Site of Screw Filter Press