Knowledge about Waste liquid evaporator

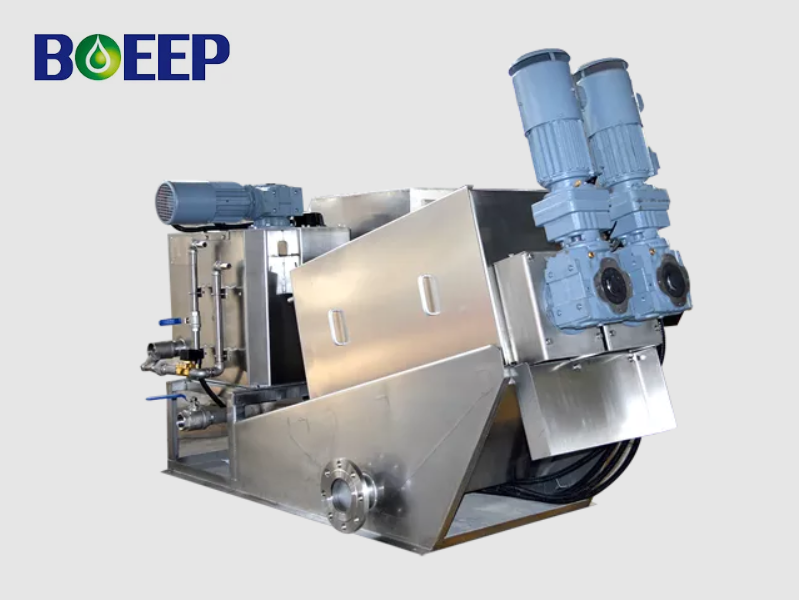

Introduction to Waste liquid evaporator

A waste liquid evaporator is a specialized industrial device designed to reduce the volume of waste liquids by evaporating the water content. This process helps concentrate valuable materials or safely dispose of hazardous waste. Typically used in industries like chemical manufacturing, food processing, and wastewater treatment, the evaporator uses heat to accelerate the evaporation of water, leaving behind a more manageable residue or concentrated waste product. The system helps save on disposal costs, improve sustainability, and comply with environmental regulations.

Key Features & Advantages

In summary, a waste liquid evaporator offers an efficient, cost-effective, and environmentally friendly solution for managing and reducing the volume of waste liquids, making it an essential tool in many industrial applications.

Volume Reduction

Significantly reduces the volume of waste liquid, which lowers transportation, storage, and disposal costs. This is particularly beneficial for industries with large amounts of wastewater or effluent.

Concentrated Waste for Easier Disposal

The evaporation process leaves behind a concentrated waste that is easier to handle, store, or dispose of, and in some cases, can be used for further treatment or energy recovery.

Environmental Benefits

By minimizing waste volume and reducing the need for hazardous chemical treatment or landfill disposal, waste liquid evaporators contribute to more sustainable and environmentally friendly waste management.

Cost Savings

The reduction in waste volume and improved waste management processes can result in significant cost savings for businesses, including savings on disposal fees and raw material costs.

Application

Comparison of Waste Liquid Evaporator & Sludge Dryer & Sludge Dewatering

Waste Liquid Evaporator

Function: A waste liquid evaporator is designed to remove water from waste liquids, concentrating the solid or semi-solid components of the waste. This process uses heat to accelerate the evaporation of water, leaving behind concentrated residuals.

Target: Primarily used for liquid waste with a high water content.

Mechanism: Works by applying heat to evaporate water from the liquid waste, often under vacuum conditions to reduce energy consumption.

Output: Concentrated waste liquid or slurry with reduced volume, making disposal or further processing easier.

Use Cases: Chemical industries, food processing, wastewater treatment, and industries dealing with liquid waste requiring volume reduction.

Sludge Dryer

Function: A sludge dryer removes moisture from thickened sludge, converting it into dry, manageable solids. The drying process typically involves heat and airflow to evaporate moisture.

Target: Solid or semi-solid sludge, often resulting from wastewater treatment or industrial processes.

Mechanism: Uses heat and airflow to remove moisture from the sludge, often in rotating drums, fluidized bed systems, or conveyor dryers.

Output: Concentrated waste liquid or slurry with reduced volume, making disposal or further processing easier.

Use Cases: Municipal wastewater treatment plants, industrial processes producing sludge, or in waste-to-energy applications.

Sludge Dewatering

Function: Sludge dewatering is a mechanical process that reduces the water content of sludge by separating the liquid portion (usually water) from the solid particles. This is typically done using equipment like centrifuges, filter presses, or belt filter presses.

Target: Sludge that still contains a high percentage of water, usually post-primary or secondary treatment stages in wastewater treatment.

Mechanism: Mechanical processes apply pressure or centrifugal forces to remove water from the sludge, reducing its volume and making it more solid for disposal.

Output: Thickened sludge with lower moisture content than before the dewatering process, but still not fully dry.

Use Cases: Commonly used in municipal wastewater treatment plants and industries producing large amounts of sludge, like food processing or chemical plants.

Certifications & Honors

Frequently Asked Questions

Q: What types of waste liquids can be treated by a waste liquid evaporator?

A: It can treat industrial effluents, chemical waste, food processing byproducts, and wastewater.

Q: How does a waste liquid evaporator save energy?

A: It saves energy using multi-effect evaporation, heat recovery systems, and vacuum evaporation.

Q: Can a waste liquid evaporator handle hazardous waste?

A: Yes, it can handle hazardous waste with special materials and compliance with safety regulations.

Q: How much water does a waste liquid evaporator remove from the waste?

A: It can reduce the volume of waste liquids by 80% to 95%, depending on the system.

Q: What are the main maintenance requirements for a waste liquid evaporator?

A: Routine checks include cleaning heat exchangers, monitoring temperature/pressure, and inspecting seals.

Get a Quote Today!

Looking for the keychain you want? We’ve got you covered!