What is Belt Filter Press

The Belt Filter Press (BFP) is a highly efficient industrial system designed for solid/liquid separation, primarily used in sludge dewatering across industries such as chemicals, mining, and water treatment. The process involves dosing incoming sludge or slurry with polymers to bind fine particles, followed by pressing the mixture through a series of rollers to extract excess water. This results in a compact cake with high solids content, lowering transport and disposal costs by reducing water weight. Known for its versatility, the BFP handles a wide range of sludges and is often integrated with components like Gravity Drainage Decks to enhance overall dewatering performance, making it a cost-effective solution for municipal and industrial applications.

Key Features of Belt Filter Press

Cost-Effective Installation

Affordable, easy setup for various dewatering needs.

Energy Efficiency

Low power consumption with automated operation, reducing supervision.

Compact High Capacity

Small footprint with high dewatering capacity, ideal for tight spaces.

Reliable Performance

Consistent results with low maintenance, thanks to durable design.

Efficient Pre-Thickening

Large filter area for effective thickening and smooth processing.

Application Scenarios for Belt Filter Press

The Belt Filter Press is widely used in municipal and industrial sludge treatment, production by-products, mine tailings, drilling, tunneling, and processing waste from abattoirs and rendering plants.

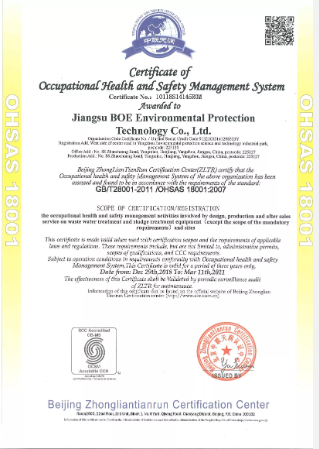

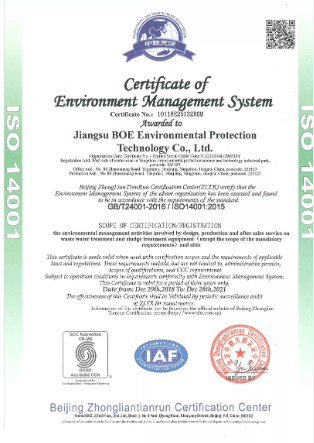

Certifications Showcase

Keep in touch with us

For any inquiries or specific needs, our customer service team is here to help. We’ll provide you with comprehensive product details, address all your questions, and offer tailored solutions to best meet your requirements.

Mob: +86-18519750525

E-mail: boe@boeep.com

Frequently Asked Questions

What types of waste liquids can be treated by a waste liquid evaporator?

It can treat industrial effluents, chemical waste, food processing byproducts, and wastewater.

How does a waste liquid evaporator save energy?

It saves energy using multi-effect evaporation, heat recovery systems, and vacuum evaporation.

Can a waste liquid evaporator handle hazardous waste?

Yes, it can handle hazardous waste with special materials and compliance with safety regulations.

How much water does a waste liquid evaporator remove from the waste?

It can reduce the volume of waste liquids by 80% to 95%, depending on the system.

What are the main maintenance requirements for a waste liquid evaporator?

Routine checks include cleaning heat exchangers, monitoring temperature/pressure, and inspecting seals.

Related Products

Explore complementary equipment for the Belt Filter Press to boost dewatering efficiency and optimize plant performance.