| Availability: | |

|---|---|

| Quantity: | |

YDL303

BOEEP

YDL

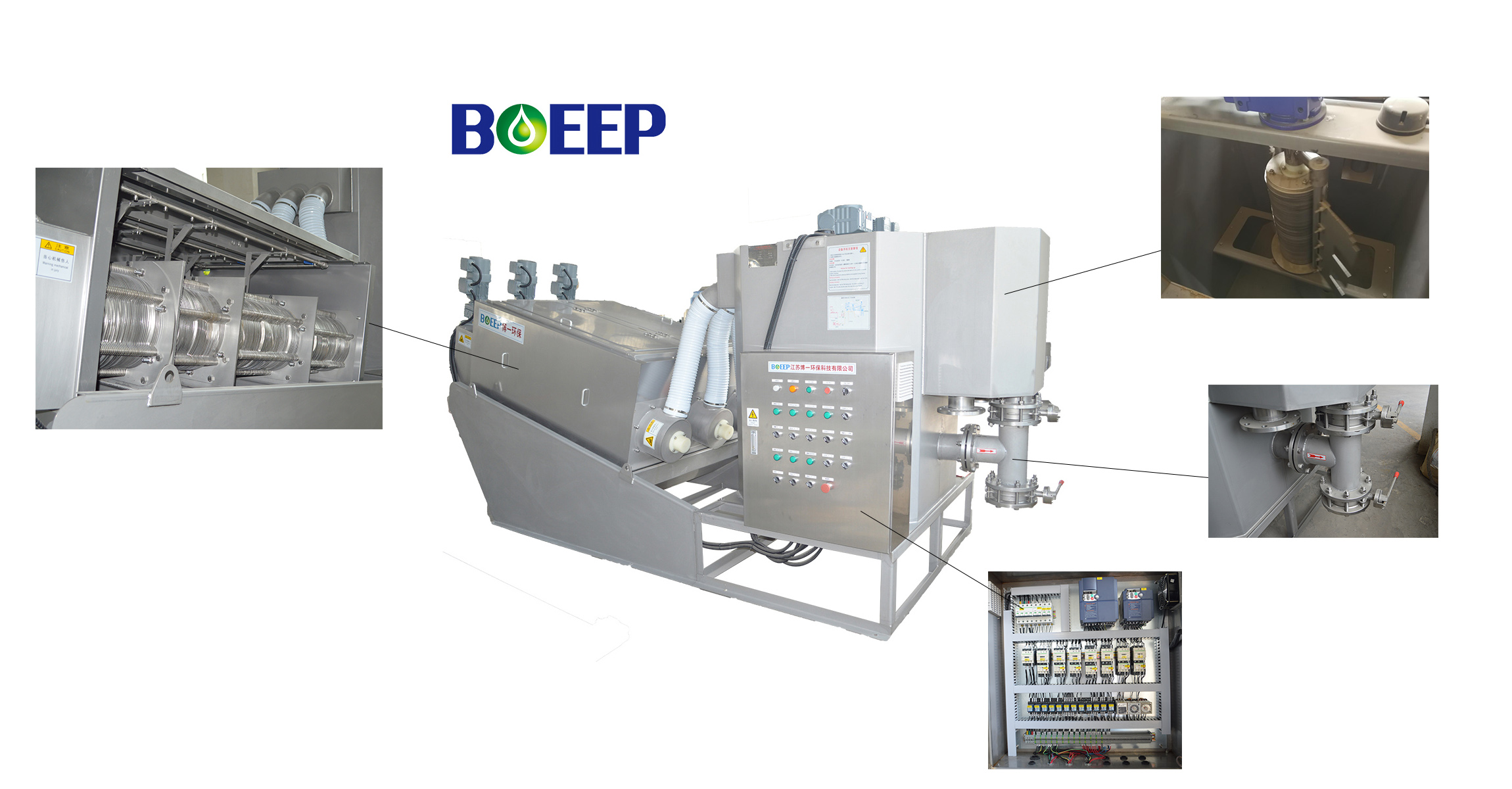

The Pre-thickening Volute Screw Press offers a new approach to sludge handling by combining initial concentration and efficient dewatering within one compact piece of equipment. Designed for both municipal and industrial wastewater facilities, it features a two-stage volute screw mechanism paired with intelligent torque regulation, enabling sludge moisture to drop from around 95% to approximately 75–80% in a single operation. With its modular layout and corrosion-resistant construction, the system is built for long-term, continuous use in demanding environments, providing stable performance while keeping energy usage and maintenance requirements low.

Dual-Stage Dewatering Technology:

Pre-Thickening Chamber: First-stage conical volute screw increases sludge solids concentration from 0.5-3% to 8-12% through gradual compression, reducing water content before entering the dewatering zone.

High-Pressure Dewatering Screw: Second-stage cylindrical screw with variable pitch (15-5mm) and adjustable backpressure plate achieves 75-80% final rate of water content,surpassing traditional single-screw presses by 5-10% dehydration efficiency.

Durable Construction:

Wear-Resistant Materials: Screw shafts coated with tungsten carbide (HRC 65) and housing lined with polyurethane (Shore A 90) resist abrasion from gritty sludge, extending service life by 20% compared to stainless steel alternatives.

IP68-Sealed Bearings: Double-lip seals and automatic lubrication system prevent sludge ingress, reducing bearing failure by 40% in high-solid content applications (TS ≥15%).

Intelligent Control System:

VFD-Driven Torque Adjustment: Real-time torque sensor (accuracy ±2%) automatically modulates screw speed (5-30 RPM) based on sludge viscosity, optimizing energy use (0.3-0.5kWh/ton sludge) and preventing blockages.

Remote Monitoring: IoT-enabled PLC interface provides real-time data on throughput (5-20m³/h), power consumption, and maintenance alerts via cloud-based software.

Municipal Wastewater Plants: Efficiently dewater primary and secondary sludge from activated sludge processes, reducing landfill disposal volume by 60%.

Industrial Effluent Treatment: Handles high-organic sludge from food & beverage, chemical, and pharmaceutical industries, maintaining stable dehydration performance for TS 1-10%.

Sludge Thickening Stations: Pre-concentrates low-concentration sludge (TS 0.3-1%) before further treatment, enhancing overall plant capacity by 30%.

Energy Efficiency Leadership: 30% lower power consumption than traditional belt presses, achieved through optimized screw geometry and load-responsive drive systems.

Low Maintenance Design: Quick-release shaft modules (1-hour replacement) and self-cleaning flight edges reduce downtime by 50%, supported by a 3-year warranty on wear components.

Space-Saving Solution: 40% smaller footprint (2.5m x 1.2m x 2m) than comparable dewatering systems, ideal for retrofitting into existing treatment lines with limited space.

The Volute Sludge Dewatering system consists of the screw module, drive assembly, filtrate collection unit, pre-thickening and mixing section, and overall support frame. During operation, sludge is pumped into the mixing chamber, where a polymer dosing pump adds a controlled amount of conditioning polymer. Driven by the mixing motor, the sludge and polymer are thoroughly blended, forming stable flocs.

Once the mixture reaches the high-level point detected by the level sensor, a signal is sent to activate the screw module. The conditioned sludge then enters the screw body, where it is gradually conveyed toward the discharge end by the rotating screw shaft. As pressure builds along the conveying path, water is expelled through the gaps between the fixed and moving rings, while the separated filtrate is collected below.

Screw body

Screw body is composed of fixed annular plates, moveable annular plates, screw shaft, screw, gasket and lots of junction plate. The front part of the main body is the thickening part, and the ending part is dewatering part. So the thickening and dewatering of the sludge can be finished in one canister. Sludge will be transported to the dewatering department after being thickened in the thickening department. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance, and the back platen clogging. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Driving device

Drive device is the power source of the equipment, and the performance of drive device can affect the equipment performance directly. For this reason, the motor our company adopts has a superior performance with IP55 and F level. Frequency conversion starting and speed control mode can suit for different application conditions to avoid the impact of the load.

Filtrate receiver

Filtrate receiver, welded by plate, is used to collect filtrate pressed by screw body. Filtrate receiver is welded to the side plates directly, and there are flanges on the side to connect the external devices.

The mixing system is used to make the sludge and polymer fully mixed in the thickening tank, the sludge can be flocculated to be gathered together, meanwhile, some of the water will be filtrated in the thickening system due to the gravity function, and the formed flocs will be transported to the screw body to press and dewater. There are sludge inlet, overflow port, polymer feed port and vent nozzle in mixing tank. Also there is the level adjusting device to adjust the sludge inleting amount. |

| Parameter design | |

| Type:YDL303 | Dimension:L4000×W1630×H1900(mm) |

| Capacity:120-210kgds/h | Power:3.35kw |

| Protection Level:IP55 F | Power Supply:380V/3/50Hz or customize |

| Outlet sludge moisture content:75-85% | Polymer feeding rate:DS 0.2~1% |

| Flush water:120L/h | Water supply pressure:≥0.2MPa |

| Equipment weight:1100kg | Operating weight:1850kg |

| Screw body | Pre thickening mixing system |

| Diameter × Length:Φ300×2260(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:3pcs | Volume:1400L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:0.75×3KW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

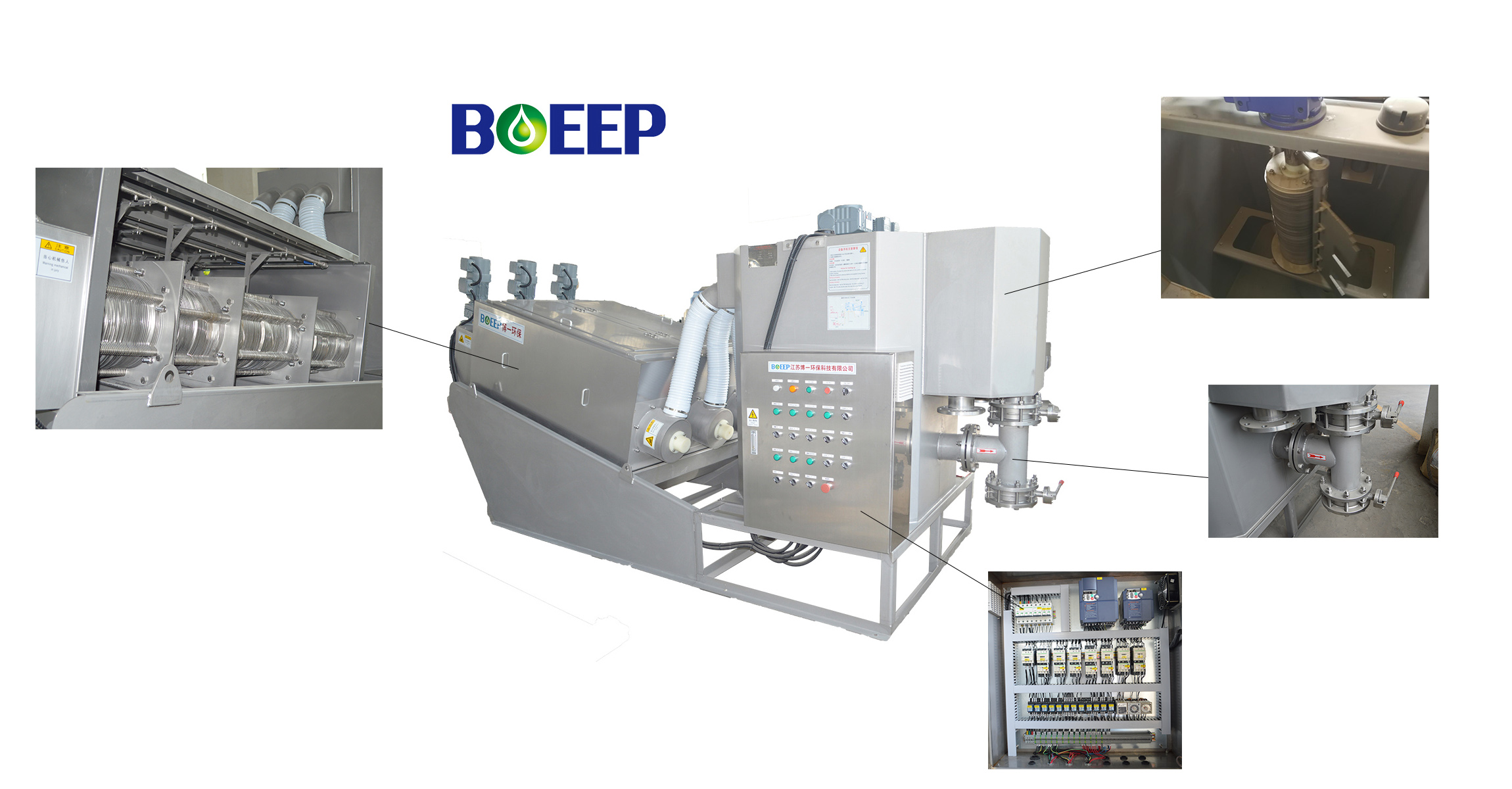

The Pre-thickening Volute Screw Press offers a new approach to sludge handling by combining initial concentration and efficient dewatering within one compact piece of equipment. Designed for both municipal and industrial wastewater facilities, it features a two-stage volute screw mechanism paired with intelligent torque regulation, enabling sludge moisture to drop from around 95% to approximately 75–80% in a single operation. With its modular layout and corrosion-resistant construction, the system is built for long-term, continuous use in demanding environments, providing stable performance while keeping energy usage and maintenance requirements low.

Dual-Stage Dewatering Technology:

Pre-Thickening Chamber: First-stage conical volute screw increases sludge solids concentration from 0.5-3% to 8-12% through gradual compression, reducing water content before entering the dewatering zone.

High-Pressure Dewatering Screw: Second-stage cylindrical screw with variable pitch (15-5mm) and adjustable backpressure plate achieves 75-80% final rate of water content,surpassing traditional single-screw presses by 5-10% dehydration efficiency.

Durable Construction:

Wear-Resistant Materials: Screw shafts coated with tungsten carbide (HRC 65) and housing lined with polyurethane (Shore A 90) resist abrasion from gritty sludge, extending service life by 20% compared to stainless steel alternatives.

IP68-Sealed Bearings: Double-lip seals and automatic lubrication system prevent sludge ingress, reducing bearing failure by 40% in high-solid content applications (TS ≥15%).

Intelligent Control System:

VFD-Driven Torque Adjustment: Real-time torque sensor (accuracy ±2%) automatically modulates screw speed (5-30 RPM) based on sludge viscosity, optimizing energy use (0.3-0.5kWh/ton sludge) and preventing blockages.

Remote Monitoring: IoT-enabled PLC interface provides real-time data on throughput (5-20m³/h), power consumption, and maintenance alerts via cloud-based software.

Municipal Wastewater Plants: Efficiently dewater primary and secondary sludge from activated sludge processes, reducing landfill disposal volume by 60%.

Industrial Effluent Treatment: Handles high-organic sludge from food & beverage, chemical, and pharmaceutical industries, maintaining stable dehydration performance for TS 1-10%.

Sludge Thickening Stations: Pre-concentrates low-concentration sludge (TS 0.3-1%) before further treatment, enhancing overall plant capacity by 30%.

Energy Efficiency Leadership: 30% lower power consumption than traditional belt presses, achieved through optimized screw geometry and load-responsive drive systems.

Low Maintenance Design: Quick-release shaft modules (1-hour replacement) and self-cleaning flight edges reduce downtime by 50%, supported by a 3-year warranty on wear components.

Space-Saving Solution: 40% smaller footprint (2.5m x 1.2m x 2m) than comparable dewatering systems, ideal for retrofitting into existing treatment lines with limited space.

The Volute Sludge Dewatering system consists of the screw module, drive assembly, filtrate collection unit, pre-thickening and mixing section, and overall support frame. During operation, sludge is pumped into the mixing chamber, where a polymer dosing pump adds a controlled amount of conditioning polymer. Driven by the mixing motor, the sludge and polymer are thoroughly blended, forming stable flocs.

Once the mixture reaches the high-level point detected by the level sensor, a signal is sent to activate the screw module. The conditioned sludge then enters the screw body, where it is gradually conveyed toward the discharge end by the rotating screw shaft. As pressure builds along the conveying path, water is expelled through the gaps between the fixed and moving rings, while the separated filtrate is collected below.

Screw body

Screw body is composed of fixed annular plates, moveable annular plates, screw shaft, screw, gasket and lots of junction plate. The front part of the main body is the thickening part, and the ending part is dewatering part. So the thickening and dewatering of the sludge can be finished in one canister. Sludge will be transported to the dewatering department after being thickened in the thickening department. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance, and the back platen clogging. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Driving device

Drive device is the power source of the equipment, and the performance of drive device can affect the equipment performance directly. For this reason, the motor our company adopts has a superior performance with IP55 and F level. Frequency conversion starting and speed control mode can suit for different application conditions to avoid the impact of the load.

Filtrate receiver

Filtrate receiver, welded by plate, is used to collect filtrate pressed by screw body. Filtrate receiver is welded to the side plates directly, and there are flanges on the side to connect the external devices.

The mixing system is used to make the sludge and polymer fully mixed in the thickening tank, the sludge can be flocculated to be gathered together, meanwhile, some of the water will be filtrated in the thickening system due to the gravity function, and the formed flocs will be transported to the screw body to press and dewater. There are sludge inlet, overflow port, polymer feed port and vent nozzle in mixing tank. Also there is the level adjusting device to adjust the sludge inleting amount. |

| Parameter design | |

| Type:YDL303 | Dimension:L4000×W1630×H1900(mm) |

| Capacity:120-210kgds/h | Power:3.35kw |

| Protection Level:IP55 F | Power Supply:380V/3/50Hz or customize |

| Outlet sludge moisture content:75-85% | Polymer feeding rate:DS 0.2~1% |

| Flush water:120L/h | Water supply pressure:≥0.2MPa |

| Equipment weight:1100kg | Operating weight:1850kg |

| Screw body | Pre thickening mixing system |

| Diameter × Length:Φ300×2260(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:3pcs | Volume:1400L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:0.75×3KW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |