The BOEEP compact screw press is a highly efficient, energy-saving device specifically designed for dewatering biological sludge (excess activated sludge). Utilizing advanced screw compression technology, this machine dewaters liquid sludge with over 99% moisture content to 75%-80% dry solids (20%-25% solids content) in a single pass. This significantly reduces sludge volume and lowers subsequent transportation and disposal costs by up to 70%. Its compact structure is specifically designed for wastewater treatment plants, food processing facilities, and industrial parks with limited space, making it an ideal alternative to traditional belt filter presses and centrifuges.

| Availability: | |

|---|---|

| Quantity: | |

YDL353

BOEEP

YDL

| Parameter design | |

| Type:YDL353 | Protection Level:IP55 F |

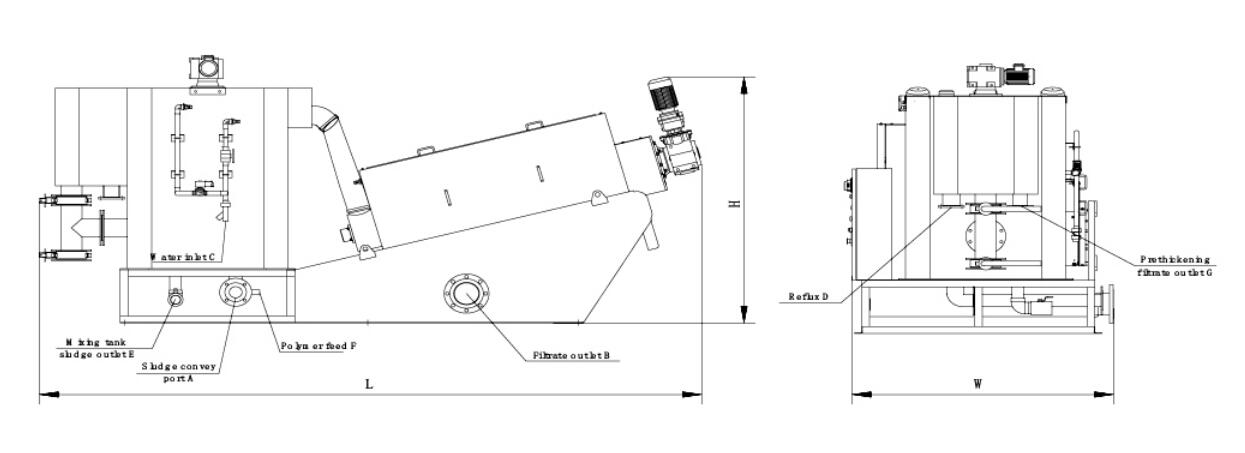

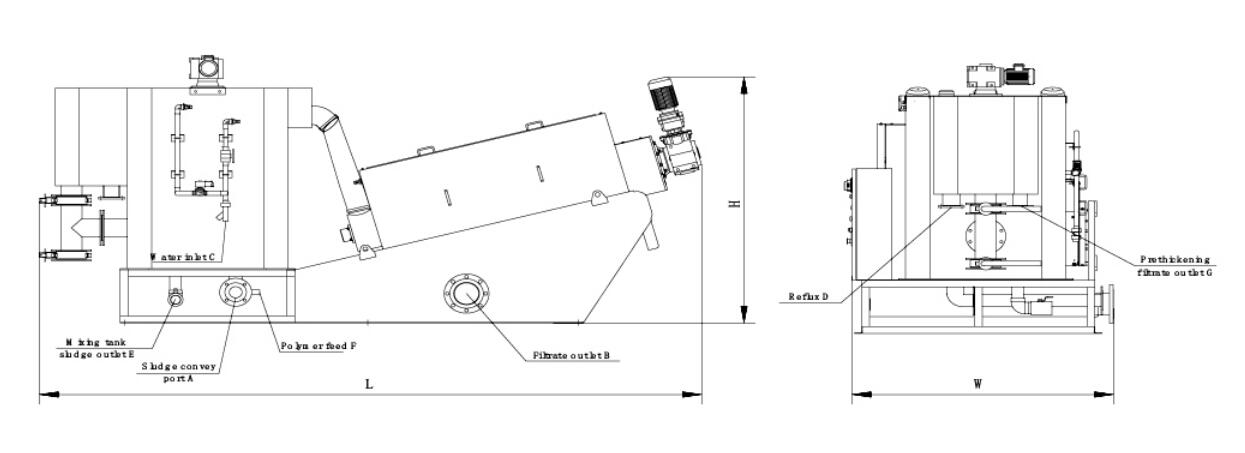

| Dimension:L4700×W1950×H2130(mm) | Power Supply:380V/3/50Hz or customize |

| Inlet sludge concentration:2500~20000mg/L | Outlet sludge moisture content:75-85% |

| Capacity:240-360kgds/h | Polymer feeding rate:DS 0.2~1% |

| Power:4.8kw | Flush water:180L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:3500kg |

| Screw body | Pre thickening mixing system |

| Diameter × Length:Φ350×2800(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:3pcs | Volume:1400L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:1.1×3kW | Motor power:1.5kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

✅ Ultimate Energy Efficiency & Cost Savings

Low-speed operation with main motor power of just 1.5-3kW, reducing energy consumption by 60% compared to traditional dewatering equipment

No high-pressure water pump flushing required, saving tens of tons of water daily

✅ High Sludge Solids Content

Multi-stage variable-diameter screw shafts and back-pressure plate design ensure steadily increasing pressure

Sludge cake moisture content consistently maintained at 75%-80% (depending on sludge properties), facilitating transportation and resource recovery

✅ Fully Automated Unattended Operation

Integrated PLC intelligent control system supports one-touch start/stop, real-time status monitoring, and fault alerts

Optional GPRS remote monitoring for seamless IoT platform integration

✅ Ultra-low maintenance costs

Core screw shafts utilize wear-resistant alloy + laser cladding technology for 2x extended lifespan

Open structure allows quick filter screen removal and cleaning, eliminating clogging risks

✅ 50% space savings

Modular compact design eliminates need for bulky auxiliary systems, ensuring flexible and convenient installation

Our screw presses provide ideal solutions for the following sectors:

Municipal wastewater treatment plants: Efficient processing of waste activated sludge (WAS) and digested sludge

Food processing industry: Treatment of slaughterhouse wastewater, fruit and vegetable processing sludge, starch residue, and brewery sludge

Chemical and pharmaceutical industries: Processing of organic chemical sludge and fermentation mycelium

Paper and pulp industry: Treatment of pulp fiber residues

Shipboard wastewater treatment: Compact design perfectly suited for onboard space constraints

High disposal costs: Significant sludge reduction directly lowers transportation and landfill/incineration expenses.

Massive energy and water consumption: No flushing pumps required, extremely low power consumption, with overall operating costs 50% lower than belt machines.

Complex operation and management: Fully automated operation requires no dedicated personnel, reducing labor costs.

Limited site space: Highly integrated equipment occupies only 2-5 square meters.

Technical Specification

| Parameter design | |

| Type:YDL353 | Protection Level:IP55 F |

| Dimension:L4700×W1950×H2130(mm) | Power Supply:380V/3/50Hz or customize |

| Inlet sludge concentration:2500~20000mg/L | Outlet sludge moisture content:75-85% |

| Capacity:240-360kgds/h | Polymer feeding rate:DS 0.2~1% |

| Power:4.8kw | Flush water:180L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:3500kg |

| Screw body | Pre thickening mixing system |

| Diameter × Length:Φ350×2800(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:3pcs | Volume:1400L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:1.1×3kW | Motor power:1.5kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

✅ Ultimate Energy Efficiency & Cost Savings

Low-speed operation with main motor power of just 1.5-3kW, reducing energy consumption by 60% compared to traditional dewatering equipment

No high-pressure water pump flushing required, saving tens of tons of water daily

✅ High Sludge Solids Content

Multi-stage variable-diameter screw shafts and back-pressure plate design ensure steadily increasing pressure

Sludge cake moisture content consistently maintained at 75%-80% (depending on sludge properties), facilitating transportation and resource recovery

✅ Fully Automated Unattended Operation

Integrated PLC intelligent control system supports one-touch start/stop, real-time status monitoring, and fault alerts

Optional GPRS remote monitoring for seamless IoT platform integration

✅ Ultra-low maintenance costs

Core screw shafts utilize wear-resistant alloy + laser cladding technology for 2x extended lifespan

Open structure allows quick filter screen removal and cleaning, eliminating clogging risks

✅ 50% space savings

Modular compact design eliminates need for bulky auxiliary systems, ensuring flexible and convenient installation

Our screw presses provide ideal solutions for the following sectors:

Municipal wastewater treatment plants: Efficient processing of waste activated sludge (WAS) and digested sludge

Food processing industry: Treatment of slaughterhouse wastewater, fruit and vegetable processing sludge, starch residue, and brewery sludge

Chemical and pharmaceutical industries: Processing of organic chemical sludge and fermentation mycelium

Paper and pulp industry: Treatment of pulp fiber residues

Shipboard wastewater treatment: Compact design perfectly suited for onboard space constraints

High disposal costs: Significant sludge reduction directly lowers transportation and landfill/incineration expenses.

Massive energy and water consumption: No flushing pumps required, extremely low power consumption, with overall operating costs 50% lower than belt machines.

Complex operation and management: Fully automated operation requires no dedicated personnel, reducing labor costs.

Limited site space: Highly integrated equipment occupies only 2-5 square meters.

Technical Specification