Is complicated sludge dewatering slowing down your sewage plant? Meet our Hassle-Free Multi-Plate Screw Dewatering system—engineered for easy operation and high efficiency. The unique 12-plate interlocking design increases solid-liquid separation by 30% versus single-plate systems, while the self-cleaning screw reduces manual intervention to just 1 hour/month. No more messy filter changes or complex calibrations—this system works smoothly with minimal oversight, even for operators new to sludge handling.

| Availability: | |

|---|---|

| Quantity: | |

MYDL304

BOEEP

MYDL

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

12 laser-cut 304 stainless steel plates (0.8mm thickness) create a 1.2m² filtration surface—20% larger than comparable models—capturing 20μm+ particles typical in secondary sludge.

Helical screw (pitch 100mm) rotates at 15 RPM, using gentle mechanical pressure to squeeze water through plate gaps without damaging floc structure.

Adjustable plate spacing (2-5mm) via handwheel lets you optimize for primary sludge (coarse solids) or tertiary sludge (fine biosolids) in under 2 minutes.

Automatic torque control: Torque sensor detects excess solids buildup and reverses screw rotation for 10 seconds, preventing motor burnout and eliminating manual unclogging.

Low-maintenance design: Only two wearable parts—screw bearings and nozzle filters—with replacement intervals of 12+ months under normal use.

Space-saving footprint: Measures 2m (L) x 1m (W) x 1.5m (H), fitting into tight spots in retrofitted plants—even alongside existing clarifiers.

2.2kW IE5 motor (super-premium efficiency) uses 50% less electricity than a traditional belt press, saving $3,000+ annually in a medium-sized plant.

Internal flushing system: Recycles clarified water from the plant’s effluent tank, using just 0.3m³/h—ideal for drought-prone regions like California or Australia.

Municipal Sewage Treatment: Handles primary sludge (from primary clarifiers, 3-5% solids) and secondary sludge (from aeration tanks, 0.5-1% solids) with equal efficiency.

Industrial Wastewater: Effective for food processing sludge (low fiber), textile dye sludge (organic matter), and small-scale manufacturing waste (non-abrasive solids).

Decentralized Plants: Trusted by towns with populations under 50,000—proven in 50+ small-scale systems in Texas and Ontario, where space and staffing are limited.

User-Friendly Design: Intuitive HMI panel with 4-button control—operators can start/stop the system and adjust settings after a 30-minute training session.

Proven Reliability: Tested in 100+ sewage plants worldwide, including Washington, DC’s Blue Plains Advanced Wastewater Treatment Plant, with a 98% uptime record over 5 years.

Cost Savings: Reduces labor costs by 60% (no dedicated operator needed) and energy bills by 40%—payback period typically under 18 months for plants processing 50m³/day.

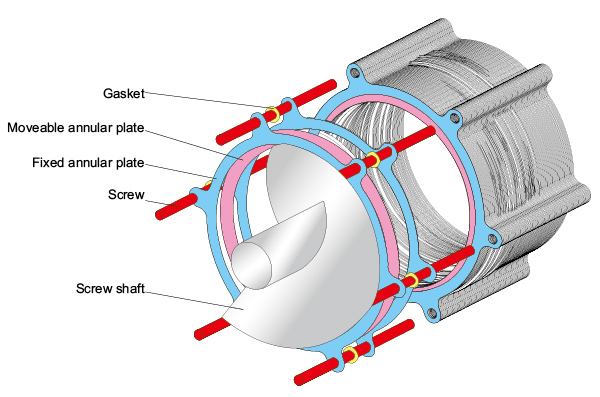

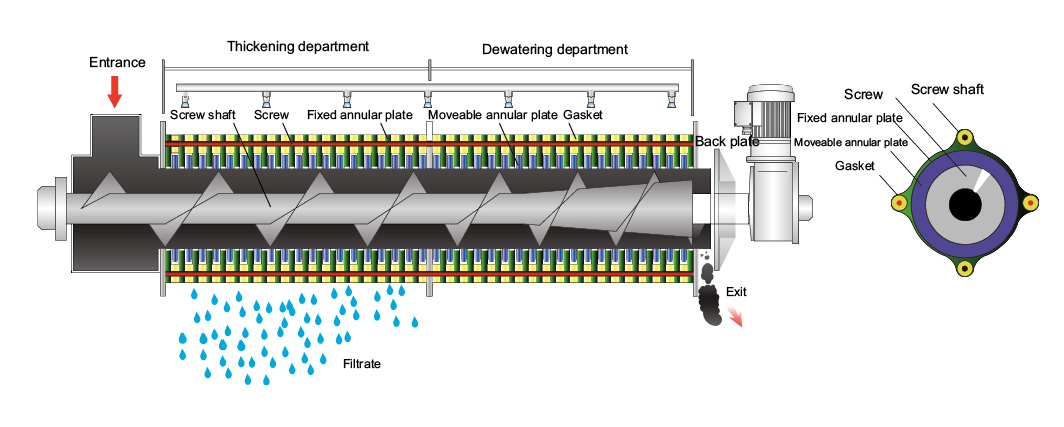

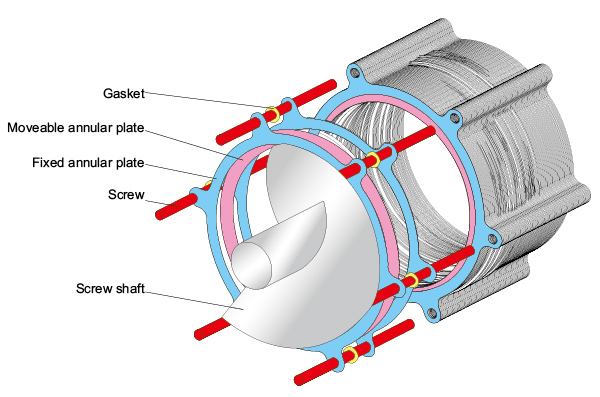

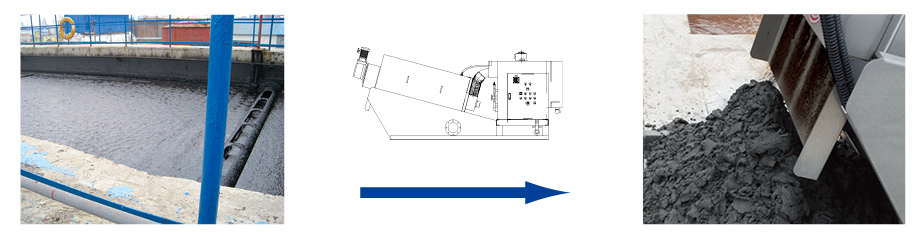

Structure Principle

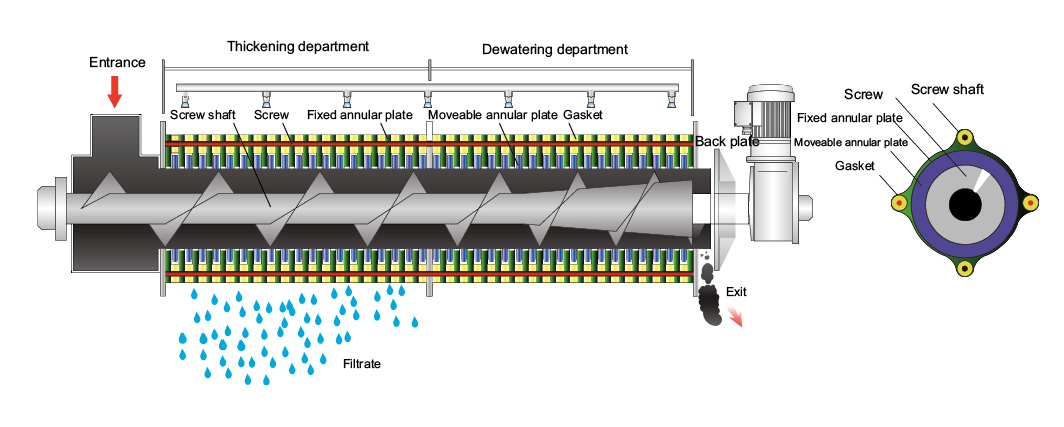

The main structure of the multi-plate volute screw sludge dewatering is made of multiple fixed ring and moveable ring with the screw shaft running through it. The front part is concentrating section, and it can concentrate the sludge. The ending part is dehydrating section and it can dewater sludge. The two work steps can be done in one box. The volute dewatering equipment has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

Working Principle

The multi-plate volute screw sludge dewatering is a new type of solid-liquid separator which uses the mechanical principle of screw press. It reaches the purpose of dewatering sludge by the powerful extrusion pressure of changing the screw diameter, distance and the tiny spacing between moveable ring and fixed ring.

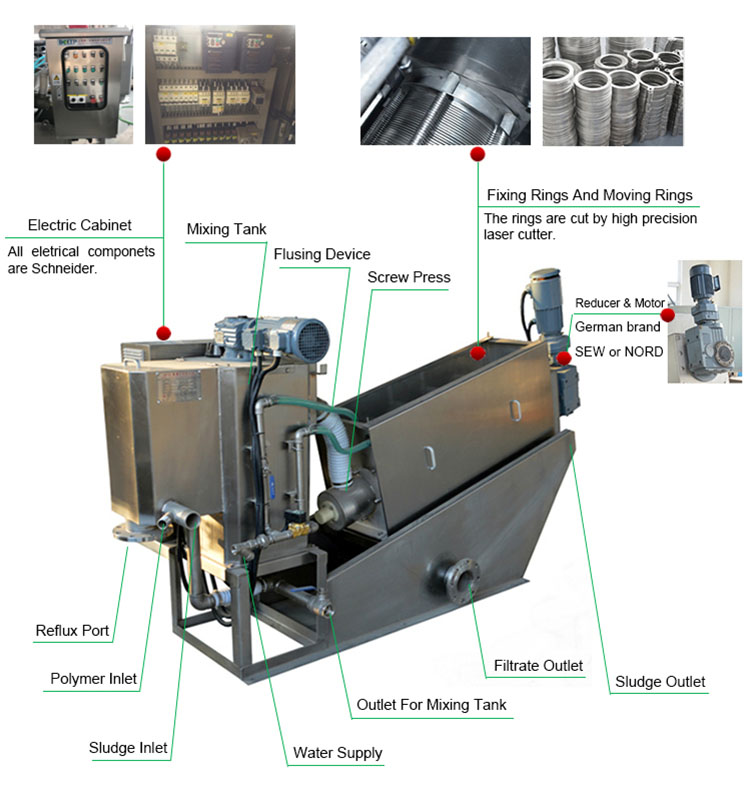

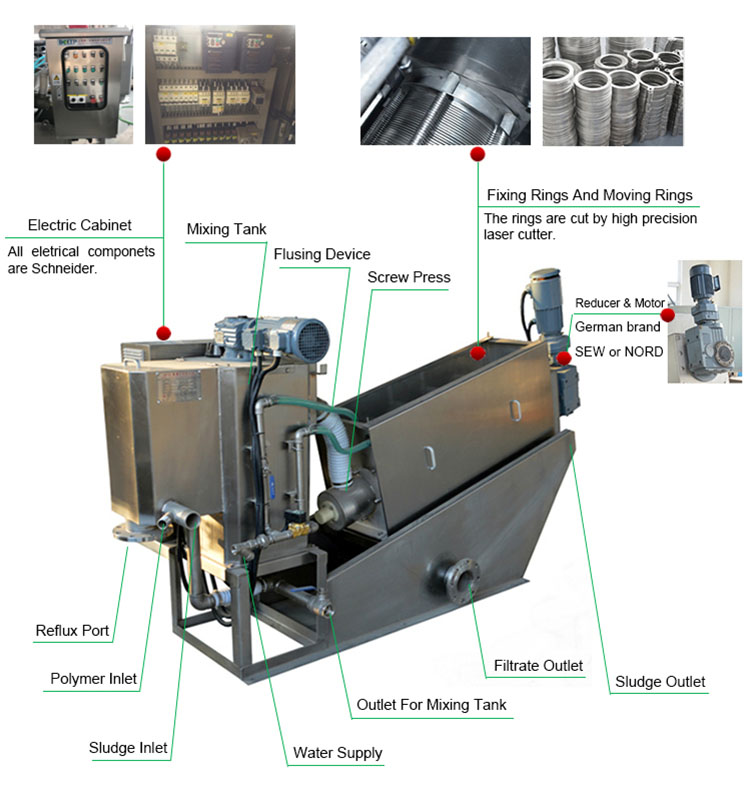

Overall Structure

| Municipal wastewater/domestic wastewater/urban sewage treatment | Landfill leachate/refuse leachate/percolated fluid | Textile |

| Cooking wastewater/kitchen waste | Animal slaughter/animal butcher | Petrochemical industry/oily sludge |

| Printing and dyeing | Brewery/wine process wastewater | Animal husbandry/livestock industry/livestock breeding |

| Pharmaceuticals industry/pharmacy | Refuse processing plant/garbage proposal | Paper making |

| Paper making | Machining wastewater | Anaerobic digested sludge/aerobic sludge |

| Food industry | Biotechnology/bioengineering/biological engineering/bioengineering | Industrial wastewater |

| Coal chemical industry | Recycled water/reclaimed water | Eletroplating industry |

| Water purification industry | Hospital sewage | Tobacco industry wastewater treatment |

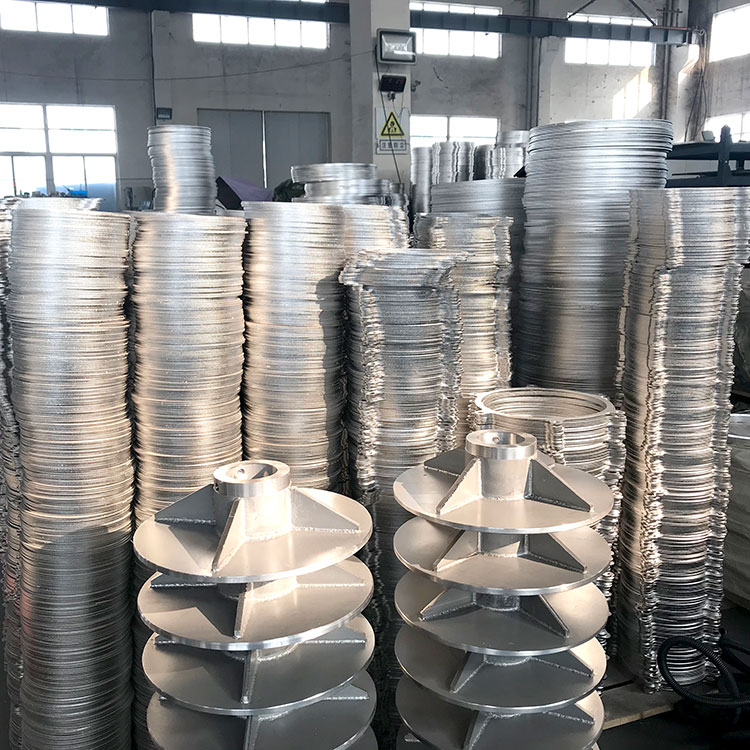

Product Details

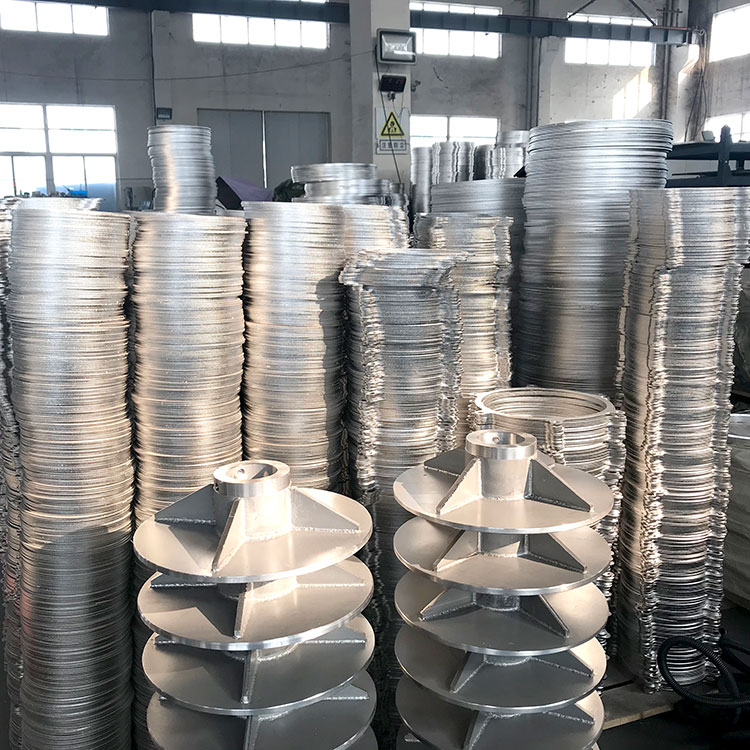

Workshop

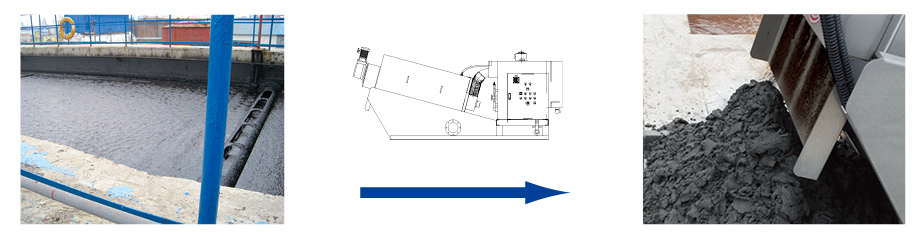

Object Site

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

12 laser-cut 304 stainless steel plates (0.8mm thickness) create a 1.2m² filtration surface—20% larger than comparable models—capturing 20μm+ particles typical in secondary sludge.

Helical screw (pitch 100mm) rotates at 15 RPM, using gentle mechanical pressure to squeeze water through plate gaps without damaging floc structure.

Adjustable plate spacing (2-5mm) via handwheel lets you optimize for primary sludge (coarse solids) or tertiary sludge (fine biosolids) in under 2 minutes.

Automatic torque control: Torque sensor detects excess solids buildup and reverses screw rotation for 10 seconds, preventing motor burnout and eliminating manual unclogging.

Low-maintenance design: Only two wearable parts—screw bearings and nozzle filters—with replacement intervals of 12+ months under normal use.

Space-saving footprint: Measures 2m (L) x 1m (W) x 1.5m (H), fitting into tight spots in retrofitted plants—even alongside existing clarifiers.

2.2kW IE5 motor (super-premium efficiency) uses 50% less electricity than a traditional belt press, saving $3,000+ annually in a medium-sized plant.

Internal flushing system: Recycles clarified water from the plant’s effluent tank, using just 0.3m³/h—ideal for drought-prone regions like California or Australia.

Municipal Sewage Treatment: Handles primary sludge (from primary clarifiers, 3-5% solids) and secondary sludge (from aeration tanks, 0.5-1% solids) with equal efficiency.

Industrial Wastewater: Effective for food processing sludge (low fiber), textile dye sludge (organic matter), and small-scale manufacturing waste (non-abrasive solids).

Decentralized Plants: Trusted by towns with populations under 50,000—proven in 50+ small-scale systems in Texas and Ontario, where space and staffing are limited.

User-Friendly Design: Intuitive HMI panel with 4-button control—operators can start/stop the system and adjust settings after a 30-minute training session.

Proven Reliability: Tested in 100+ sewage plants worldwide, including Washington, DC’s Blue Plains Advanced Wastewater Treatment Plant, with a 98% uptime record over 5 years.

Cost Savings: Reduces labor costs by 60% (no dedicated operator needed) and energy bills by 40%—payback period typically under 18 months for plants processing 50m³/day.

Structure Principle

The main structure of the multi-plate volute screw sludge dewatering is made of multiple fixed ring and moveable ring with the screw shaft running through it. The front part is concentrating section, and it can concentrate the sludge. The ending part is dehydrating section and it can dewater sludge. The two work steps can be done in one box. The volute dewatering equipment has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

Working Principle

The multi-plate volute screw sludge dewatering is a new type of solid-liquid separator which uses the mechanical principle of screw press. It reaches the purpose of dewatering sludge by the powerful extrusion pressure of changing the screw diameter, distance and the tiny spacing between moveable ring and fixed ring.

Overall Structure

| Municipal wastewater/domestic wastewater/urban sewage treatment | Landfill leachate/refuse leachate/percolated fluid | Textile |

| Cooking wastewater/kitchen waste | Animal slaughter/animal butcher | Petrochemical industry/oily sludge |

| Printing and dyeing | Brewery/wine process wastewater | Animal husbandry/livestock industry/livestock breeding |

| Pharmaceuticals industry/pharmacy | Refuse processing plant/garbage proposal | Paper making |

| Paper making | Machining wastewater | Anaerobic digested sludge/aerobic sludge |

| Food industry | Biotechnology/bioengineering/biological engineering/bioengineering | Industrial wastewater |

| Coal chemical industry | Recycled water/reclaimed water | Eletroplating industry |

| Water purification industry | Hospital sewage | Tobacco industry wastewater treatment |

Product Details

Workshop

Object Site