Tired of complicated dewatering systems? Our Easy-Operate Volute Screw Dewatering system is built for simplicity. The intuitive design lets you start dewatering in minutes, while the volute screw technology handles both organic and inorganic sludges efficiently. Whether you run a small municipal plant or a large industrial facility, this system adapts to your needs without steep learning curves.

| Availability: | |

|---|---|

| Quantity: | |

MYDL202

BOEEP

MYDL

No Expert Training Needed: A single knob adjusts the screw speed, and color-coded indicators show when it’s time for routine maintenance (every 500 hours).

Plug-and-Play Setup: Connect to your sludge pump and power supply—no complex piping or electrical work. Most installations finish in under 3 hours.

Quiet Operation: ≤75dB noise level, thanks to the rubber-insulated screw housing—friendly for plants near residential areas.

Volute screw design with 10mm-thick threads squeezes out water effectively, achieving 25-30% solids content in the cake—ideal for landfill or composting.

Processes 8 m³/h of sludge, with a built-in screen (0.3mm pores) that traps particles as small as sand, reducing carryover to the effluent.

Self-cleaning function: Reverses screw rotation for 20 seconds every hour to prevent minor clogs—no need to stop the system.

316 stainless steel construction resists corrosion from acidic or alkaline wastewater (pH 4-12).

Heavy-duty bearings rated for 10,000 hours of continuous use—backed by our 3-year warranty on moving parts.

Municipal Treatment: Handles primary and secondary sludge from clarifiers and aeration tanks, common in cities like Phoenix and Houston.

Industrial Wastewater: Effective for textile dye sludge (high color), food processing sludge (organic matter), and automotive wash water sludge (oily solids).

Decentralized Systems: Perfect for rural wastewater plants or temporary treatment sites, where ease of operation is key.

User First Design: Rated “most intuitive” by Plant Operations Today (2024), with a 95% user satisfaction score from first-time operators.

Cost-Effective Performance: Lowers operational costs by 30% compared to older belt press models, thanks to minimal labor and energy use.

Local Support Network: Free phone support 24/7, plus same-day parts delivery from 8 regional warehouses across the US.

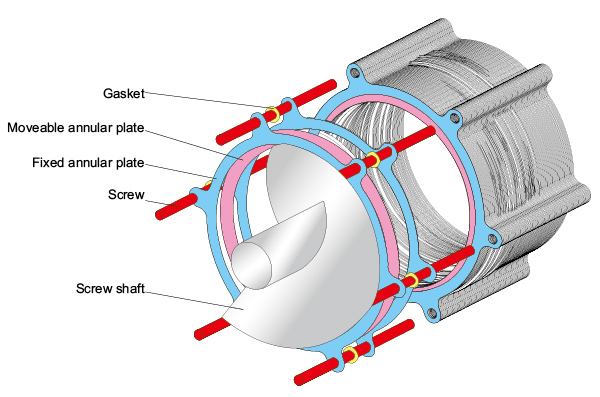

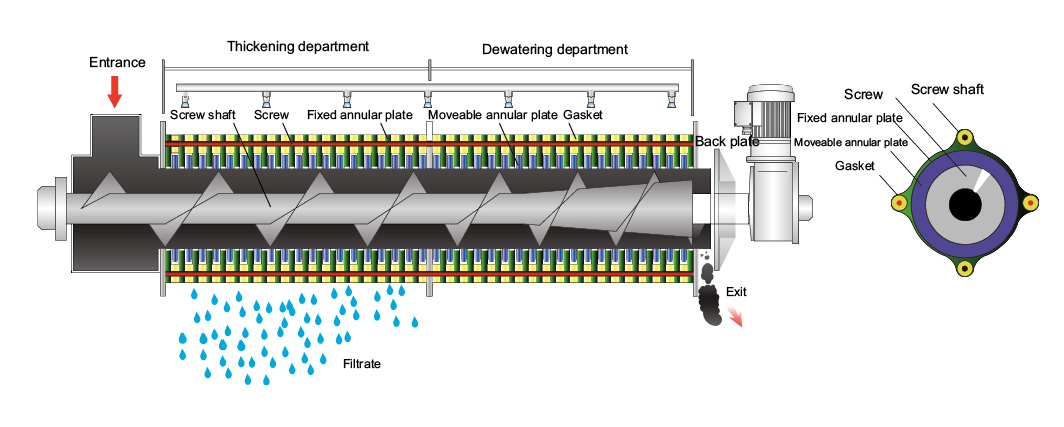

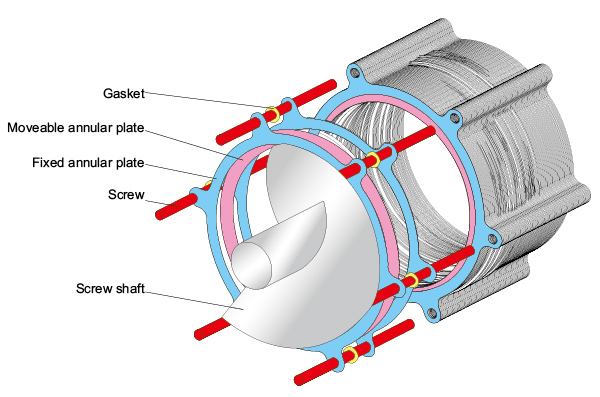

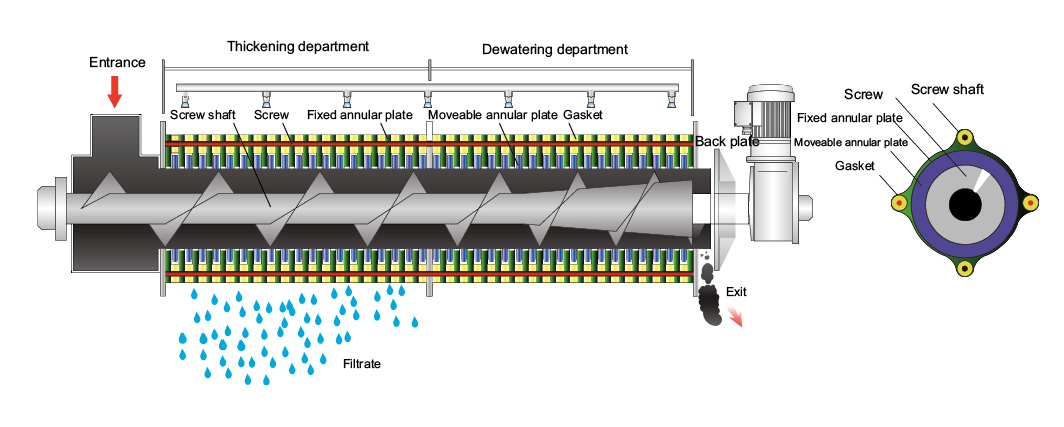

Structure & Working Principle

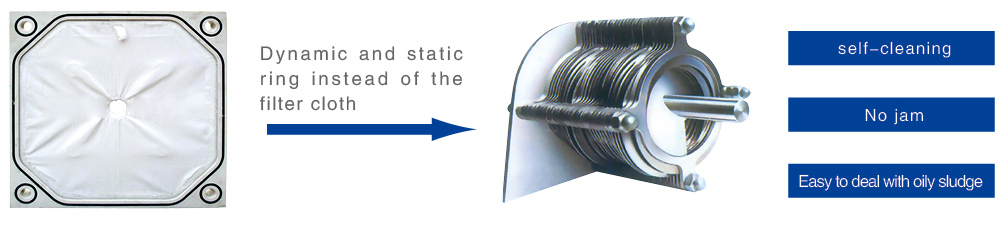

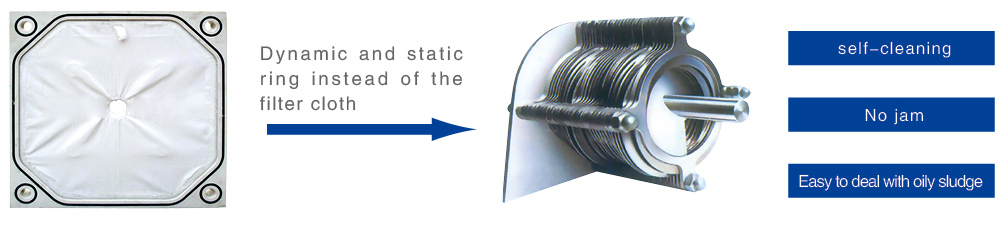

The multiple fixed rings and moveable rings with the a screw shaft running through compose the main body of the Volute Screw Filter Press Sludge Dewatering Machine in which there are two sections. The front part is responsible for thickening and the ending part does the dewatering working. It can thicken and dewater sludge in one box. It has gradually taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

After being thickened in the thickening part, the sludge will be transported to the dewatering part . In the course of progress, great pressure has been produced because the filter spacing and screw distance with the clogging of the back platen become smaller and smaller. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Model Selection

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

Product details

Project site

Workshop products

No Expert Training Needed: A single knob adjusts the screw speed, and color-coded indicators show when it’s time for routine maintenance (every 500 hours).

Plug-and-Play Setup: Connect to your sludge pump and power supply—no complex piping or electrical work. Most installations finish in under 3 hours.

Quiet Operation: ≤75dB noise level, thanks to the rubber-insulated screw housing—friendly for plants near residential areas.

Volute screw design with 10mm-thick threads squeezes out water effectively, achieving 25-30% solids content in the cake—ideal for landfill or composting.

Processes 8 m³/h of sludge, with a built-in screen (0.3mm pores) that traps particles as small as sand, reducing carryover to the effluent.

Self-cleaning function: Reverses screw rotation for 20 seconds every hour to prevent minor clogs—no need to stop the system.

316 stainless steel construction resists corrosion from acidic or alkaline wastewater (pH 4-12).

Heavy-duty bearings rated for 10,000 hours of continuous use—backed by our 3-year warranty on moving parts.

Municipal Treatment: Handles primary and secondary sludge from clarifiers and aeration tanks, common in cities like Phoenix and Houston.

Industrial Wastewater: Effective for textile dye sludge (high color), food processing sludge (organic matter), and automotive wash water sludge (oily solids).

Decentralized Systems: Perfect for rural wastewater plants or temporary treatment sites, where ease of operation is key.

User First Design: Rated “most intuitive” by Plant Operations Today (2024), with a 95% user satisfaction score from first-time operators.

Cost-Effective Performance: Lowers operational costs by 30% compared to older belt press models, thanks to minimal labor and energy use.

Local Support Network: Free phone support 24/7, plus same-day parts delivery from 8 regional warehouses across the US.

Structure & Working Principle

The multiple fixed rings and moveable rings with the a screw shaft running through compose the main body of the Volute Screw Filter Press Sludge Dewatering Machine in which there are two sections. The front part is responsible for thickening and the ending part does the dewatering working. It can thicken and dewater sludge in one box. It has gradually taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

After being thickened in the thickening part, the sludge will be transported to the dewatering part . In the course of progress, great pressure has been produced because the filter spacing and screw distance with the clogging of the back platen become smaller and smaller. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Model Selection

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

Product details

Project site

Workshop products