| Availability: | |

|---|---|

| Quantity: | |

MYDL402

BOEEP

MYDL

Overall Structure

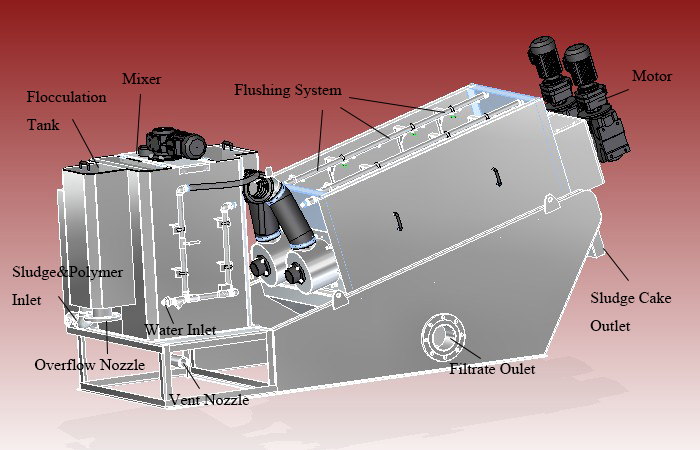

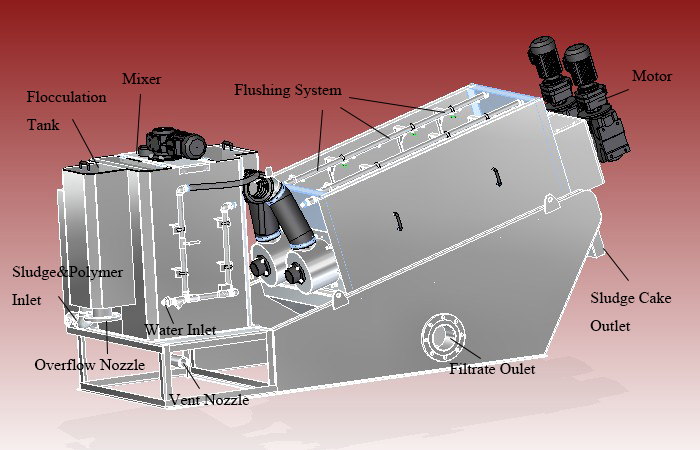

The BOEEP volute filter press dehydrator is an integrated system for sludge treatment, featuring the following key aspects:

Main Components: The equipment includes a screw body, driving device, filtrate receiver, mixing system, and a sturdy frame.

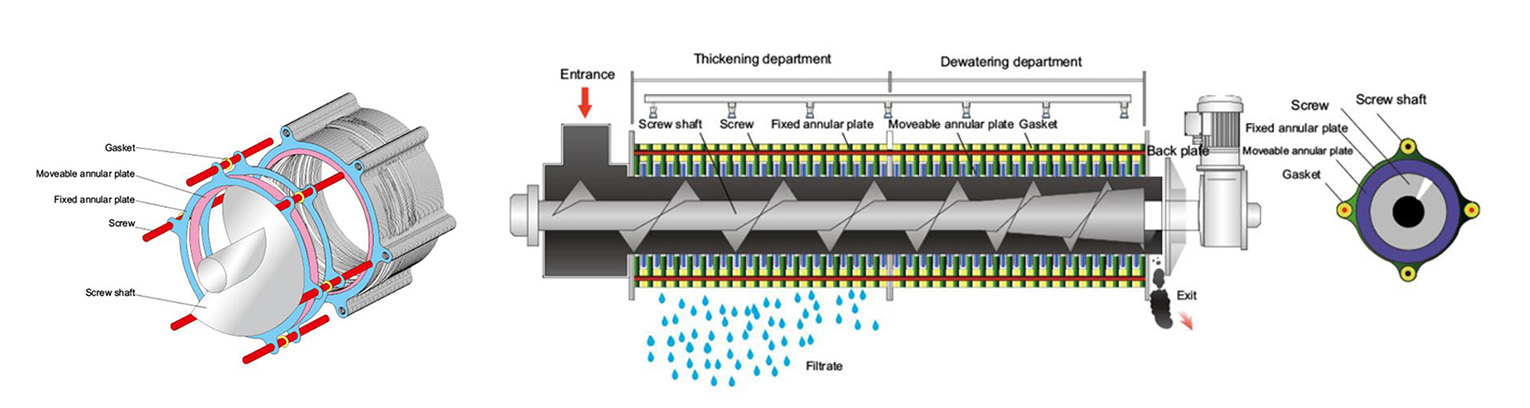

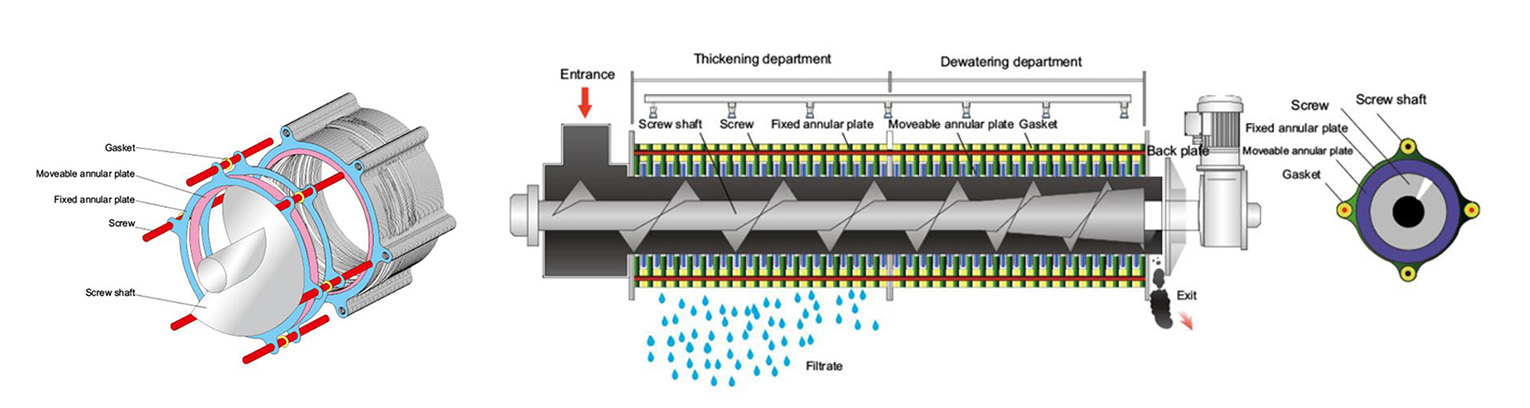

Core Mechanism: The dehydration process is driven by a unique three-part assembly: a fixed ring, a movable ring, and a central screw shaft.

Integrated Process: It seamlessly performs both sludge thickening (in the front section) and dewatering (in the latter section) within one chamber.

Key Advantage: This advanced functionality has made it a modern replacement for traditional filter cloths and centrifugal filtration techniques.

Working Principle

Operational Process of the Volute Filter Press Sludge Dehydrator

When the dehydrator is started, sludge is fed into the mixing tank by a sludge feed pump. Simultaneously, solid polymer is quantitatively dosed into the same tank via a polymer feed pump. The mixing motor then drives the mixing system to thoroughly blend the sludge and polymer, promoting the formation of flocs.

Once the liquid level in the tank reaches the upper limit set by the level sensor, the sensor triggers the motor of the screw body to initiate operation. This marks the beginning of the sludge pressing phase. The sludge enters the screw body and is gradually conveyed toward the outlet by the rotating screw shaft. During this process, the filtrate is squeezed out through the gaps between the fixed and movable annular plates, while the dewatered sludge is discharged at the end.

Application

| Printing and dyeing | Tobacco industry wastewater treatment | Hospital sewage |

| Paper making | Chemical wastewater | Coal chemical industry |

| Municipal wastewater/domestic wastewater/urban sewage treatment | Landfill leachate/refuse leachate/percolated fluid | Animal husbandry/livestock industry/livestock breeding |

| Petrochemical industry/oily sludge | Refuse processing plant/garbage proposal | Machining wastewater |

| Industrial wastewater | Animal slaughter/animal butcher | Food industry |

| Anaerobic digested sludge/aerobic sludge | Biotechnology/bioengineering/biological engineering/bioengineering | Water purification industry |

| Eletroplating industry | Recycled water/reclaimed water | Cooking wastewater/kitchen waste |

| Textile | Municipal wastewater/domestic wastewater/urban sewage treatment | Brewery/wine process wastewater |

Advantages

Suitable for any type of sludge even suitable for dewatering oil/grease rich sludge.

Low energy consumption.

Low polymer consumption.

Minimal water consumption.

Minimal noise.

Minimal maintenance and operational cost.

No need for proceeding sludge thickening.

Capable for working 24/7.

Technical Parameters

| Parameter | |

| Type:MYDL402 | Solid content:10000~50000mg/L |

| Dimension:L4960×W1760×H2100(mm) | Capacity:260-320kgds/h |

| Power:4.5kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Output sludge moisture content:75-85% |

| Polymer feeding rate:DS 0.2~1% | Flush water:160L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:4000kg |

| Screw body | Flocculated mix tank |

| Specification × Length:Φ400×3255(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:2 | Volume:About 1400L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:1.5×2kW | Motor power:1.5kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

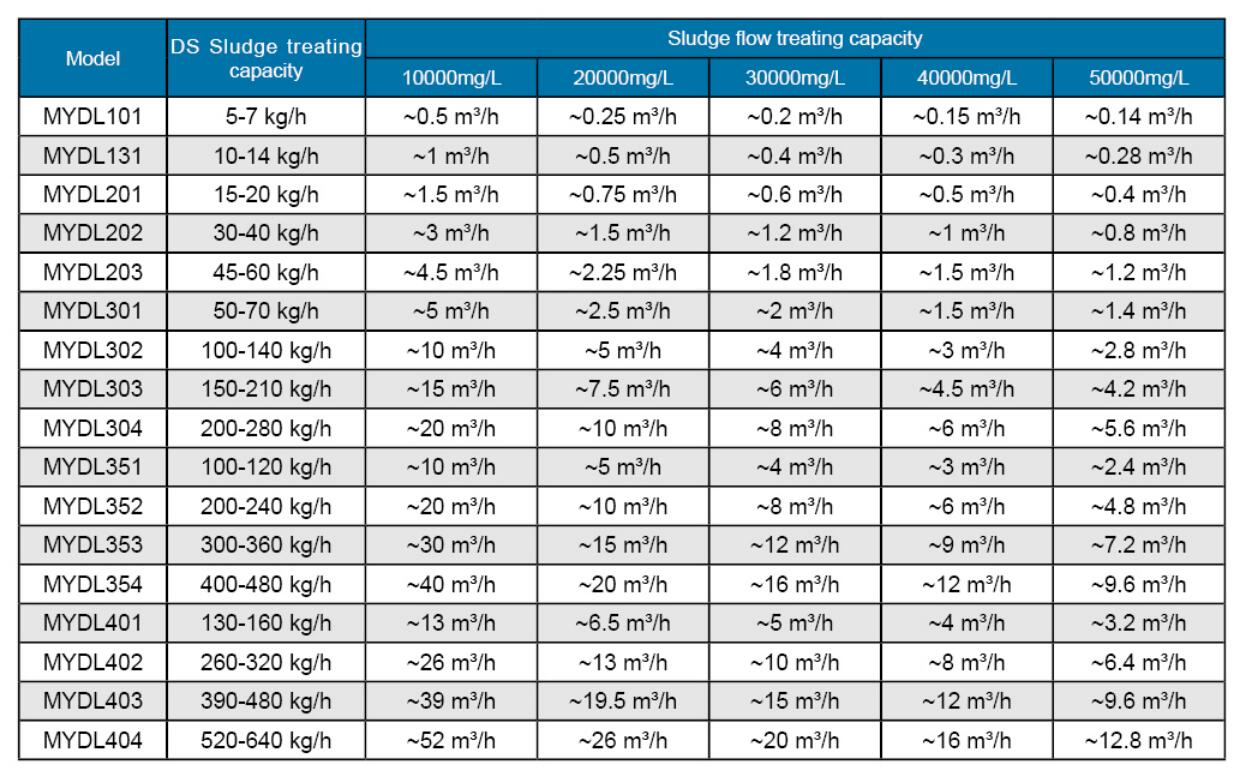

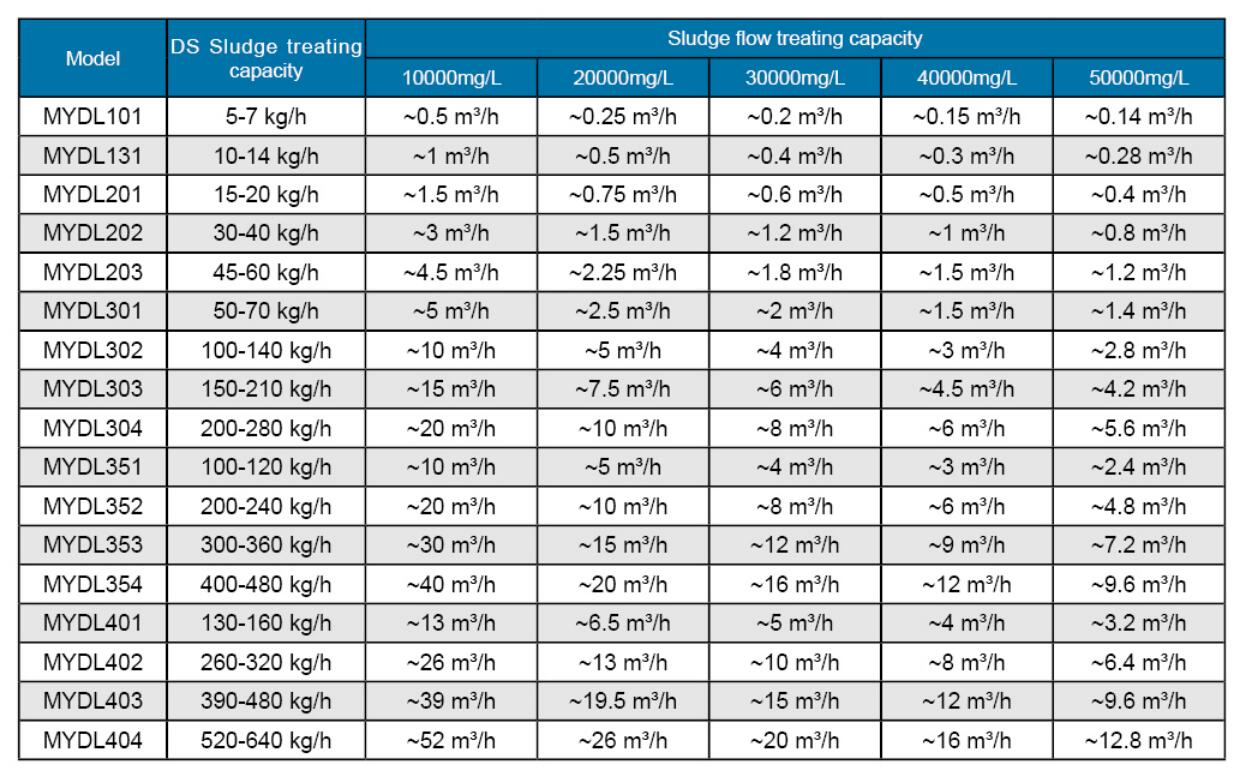

Model Choice

Product Details

Object Site

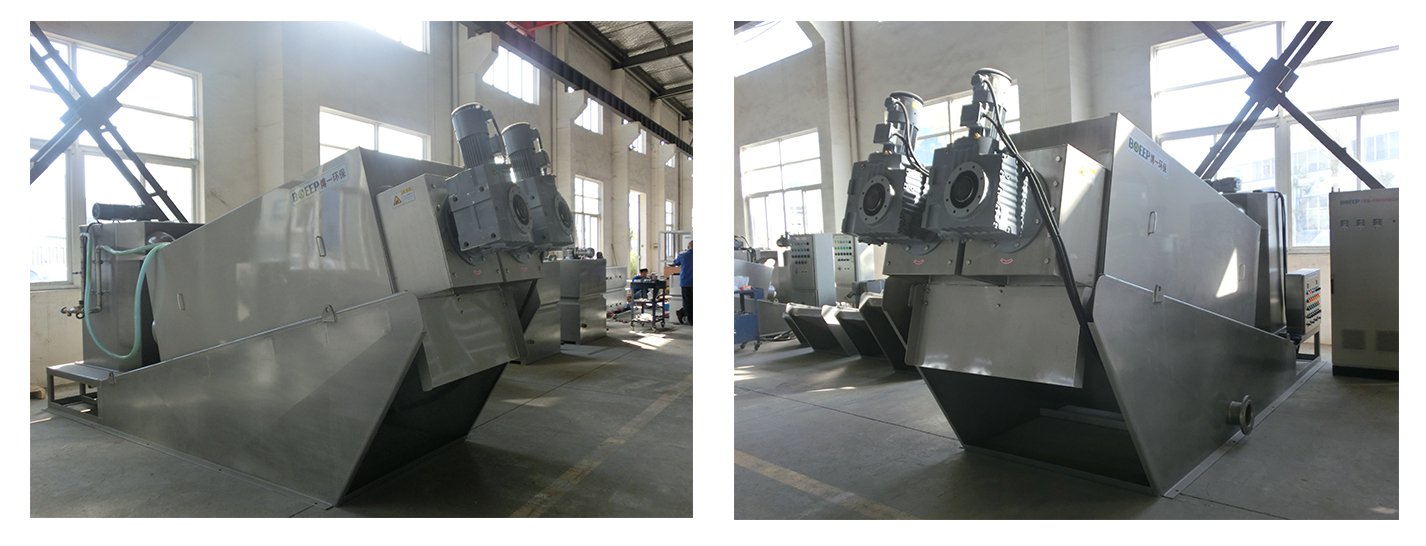

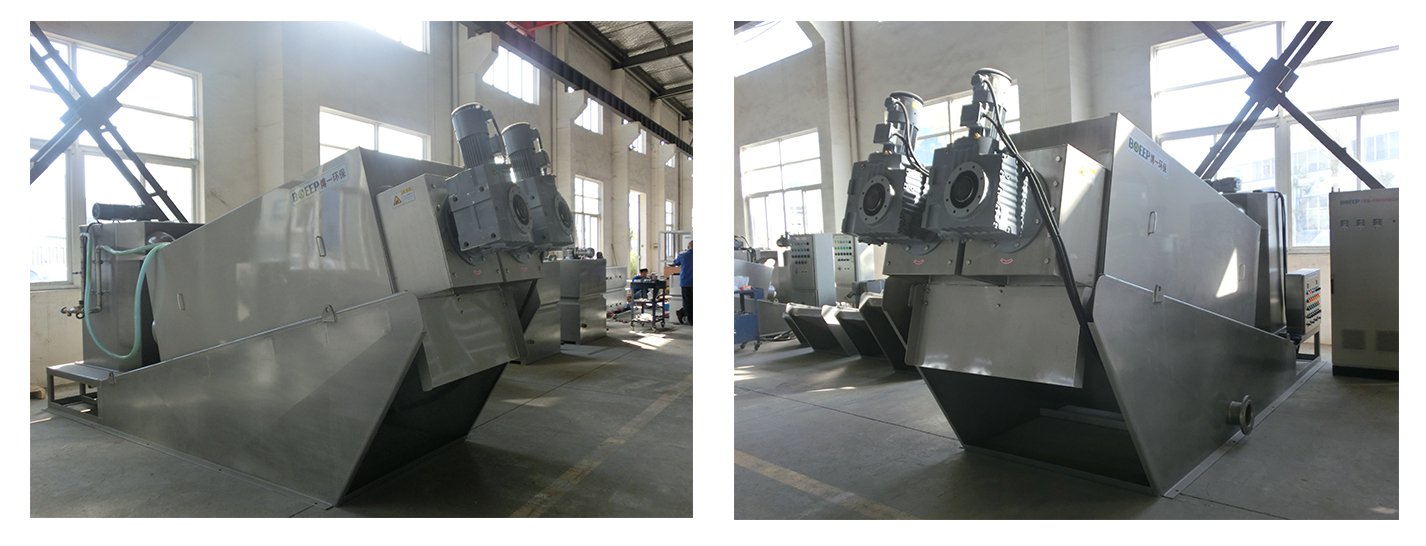

Workshop Site

Overall Structure

The BOEEP volute filter press dehydrator is an integrated system for sludge treatment, featuring the following key aspects:

Main Components: The equipment includes a screw body, driving device, filtrate receiver, mixing system, and a sturdy frame.

Core Mechanism: The dehydration process is driven by a unique three-part assembly: a fixed ring, a movable ring, and a central screw shaft.

Integrated Process: It seamlessly performs both sludge thickening (in the front section) and dewatering (in the latter section) within one chamber.

Key Advantage: This advanced functionality has made it a modern replacement for traditional filter cloths and centrifugal filtration techniques.

Working Principle

Operational Process of the Volute Filter Press Sludge Dehydrator

When the dehydrator is started, sludge is fed into the mixing tank by a sludge feed pump. Simultaneously, solid polymer is quantitatively dosed into the same tank via a polymer feed pump. The mixing motor then drives the mixing system to thoroughly blend the sludge and polymer, promoting the formation of flocs.

Once the liquid level in the tank reaches the upper limit set by the level sensor, the sensor triggers the motor of the screw body to initiate operation. This marks the beginning of the sludge pressing phase. The sludge enters the screw body and is gradually conveyed toward the outlet by the rotating screw shaft. During this process, the filtrate is squeezed out through the gaps between the fixed and movable annular plates, while the dewatered sludge is discharged at the end.

Application

| Printing and dyeing | Tobacco industry wastewater treatment | Hospital sewage |

| Paper making | Chemical wastewater | Coal chemical industry |

| Municipal wastewater/domestic wastewater/urban sewage treatment | Landfill leachate/refuse leachate/percolated fluid | Animal husbandry/livestock industry/livestock breeding |

| Petrochemical industry/oily sludge | Refuse processing plant/garbage proposal | Machining wastewater |

| Industrial wastewater | Animal slaughter/animal butcher | Food industry |

| Anaerobic digested sludge/aerobic sludge | Biotechnology/bioengineering/biological engineering/bioengineering | Water purification industry |

| Eletroplating industry | Recycled water/reclaimed water | Cooking wastewater/kitchen waste |

| Textile | Municipal wastewater/domestic wastewater/urban sewage treatment | Brewery/wine process wastewater |

Advantages

Suitable for any type of sludge even suitable for dewatering oil/grease rich sludge.

Low energy consumption.

Low polymer consumption.

Minimal water consumption.

Minimal noise.

Minimal maintenance and operational cost.

No need for proceeding sludge thickening.

Capable for working 24/7.

Technical Parameters

| Parameter | |

| Type:MYDL402 | Solid content:10000~50000mg/L |

| Dimension:L4960×W1760×H2100(mm) | Capacity:260-320kgds/h |

| Power:4.5kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Output sludge moisture content:75-85% |

| Polymer feeding rate:DS 0.2~1% | Flush water:160L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:4000kg |

| Screw body | Flocculated mix tank |

| Specification × Length:Φ400×3255(mm) | Dimension:L1000×W1000×H1400(mm) |

| Quantity:2 | Volume:About 1400L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:1.5×2kW | Motor power:1.5kw |

| Electrical Cabinet | |

| 1. Frequency converting controls dewatering body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Model Choice

Product Details

Object Site

Workshop Site