Are high equipment costs hurting your slaughter plant’s profits? Our Low-Cost Screw Filter Press offers professional-grade dewatering at a budget-friendly price—25% more affordable than similar models. Designed for slaughter waste—including blood, fat, and organ residues—this press uses a robust 8mm-pitch screw to separate solids efficiently, producing dry cake suitable for composting or incineration without breaking your budget.

| Availability: | |

|---|---|

| Quantity: | |

MYDL303

BOEEP

MYDL

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

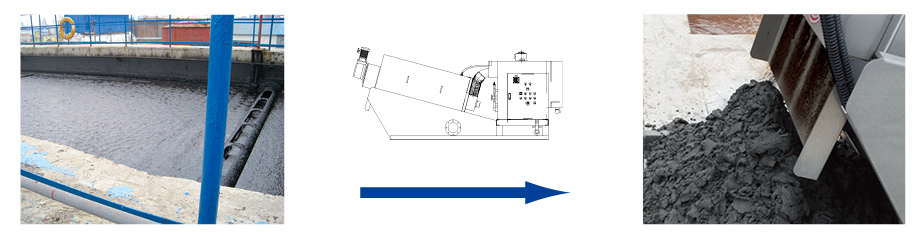

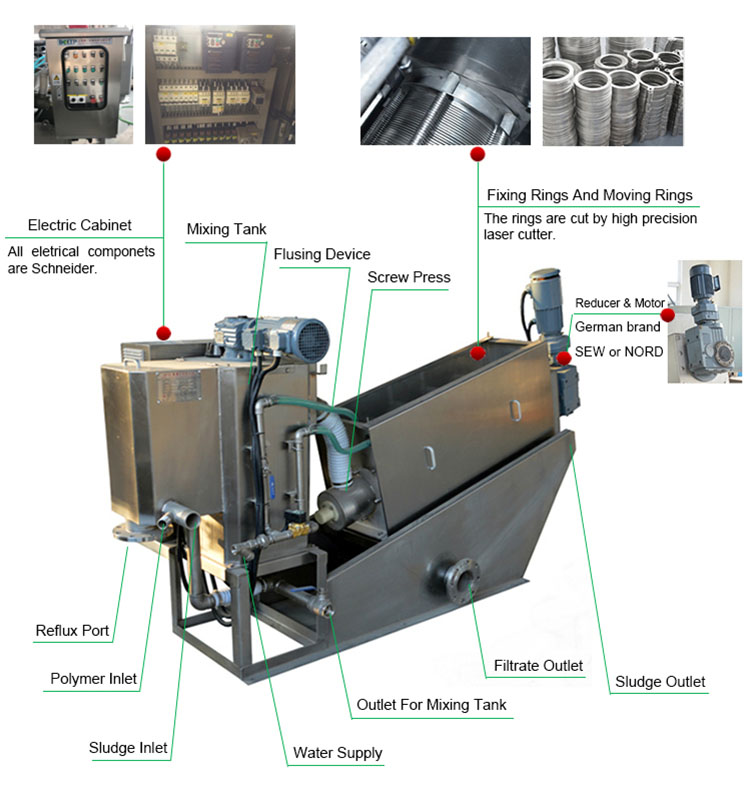

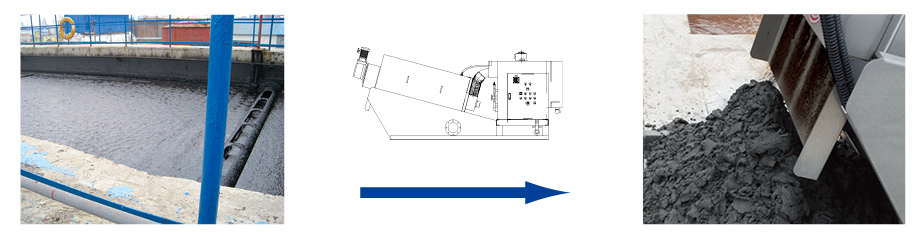

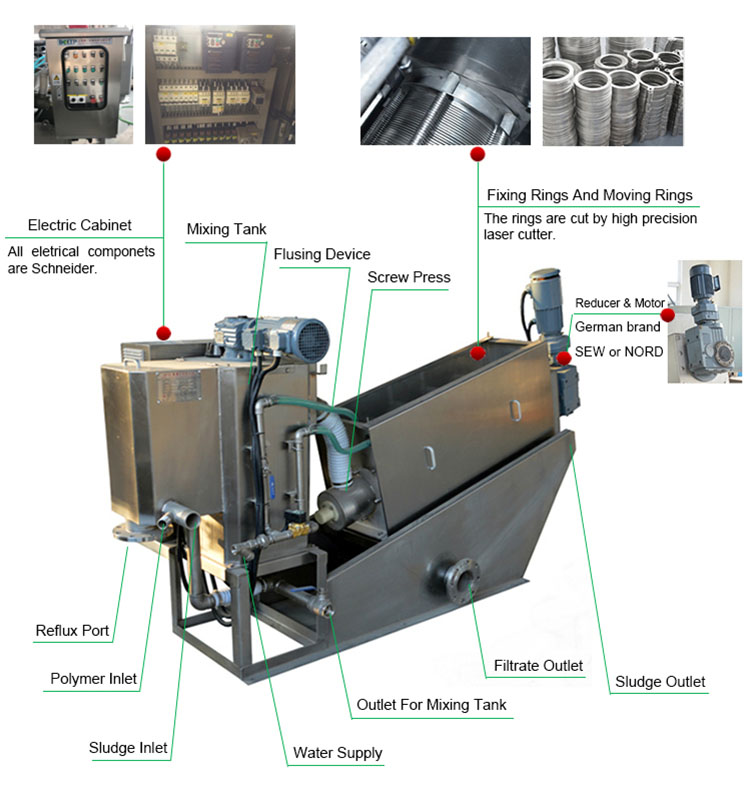

The Integrated Screw Filter Press Dewatering System offers a fully automated and economical approach to sludge treatment. Utilizing advanced screw press technology, the unit performs both thickening and dewatering within a single, simplified workflow, helping reduce energy use and overall operating expenses. Its automated polymer dosing, flocculation process, and sludge cake conveying work in coordination to manage a wide range of sludge types with minimal operator involvement. Engineered to process even challenging materials—such as oily sludge and various industrial wastewater streams—the system is well suited for municipal plants, food-processing facilities, slaughterhouses, and similar applications. Supported by BOEEP’s proven technologies, including its Volute Screw Press and Belt Filter Press solutions, the system delivers strong performance, high reliability, and low maintenance requirements, making it a dependable option in modern sludge dewatering applications.

Frame constructed with polymer-coated carbon steel (abrasion resistance ≥ 500 cycles), cutting material costs by 30% while maintaining structural integrity in wet environments.

Simple single-screw design with only 3 moving parts (screw, motor, and control valve), reducing maintenance costs by 40% compared to multi-screw systems.

Three size options:

0.5m screw (5m³/h capacity) for small butcher shops

1m screw (10m³/h) for medium slaughterhouses

1.5m screw (15m³/h) for large processing plants

8mm-pitch screw with 45° lead angle compresses fatty sludge efficiently, achieving 30-35% solids content—tested on chicken processing waste (high fat) and beef trimming sludge (high protein).

Anti-clogging filter screen (0.2mm pores) with 316 stainless steel mesh traps bone fragments and connective tissue, reducing screen replacements from monthly to quarterly.

Epoxy coating (500μm thickness) on internal components withstands lactic acid and urea in slaughter wastewater, extending service life by 20%.

Plug-and-play design: Connect to your existing sludge pump (1.5kW or higher) using standard flange fittings—no custom piping required, installation completed in 2 hours.

Automatic reverse function: Activates when pressure exceeds 3 bar, rotating the screw backward for 30 seconds to clear minor clogs—no production downtime.

Slaughterhouse Waste: Processes primary sludge from carcass washing, offal tanks, and rendering plants—handle up to 15% solids input efficiently.

Food Waste Recycling: Converts poultry litter, pork fat trimmings, and beef blood sludge into dry cake for biogas production (35% solids) or animal feed additives (40% solids).

Small-Scale Operations: Ideal for family-owned slaughterhouses (processing <500 head/day) and regional plants in countries like Brazil, where cost efficiency is critical.

Affordable Entry Point: Starting at $12,000—lower than any certified slaughter waste dewatering solution on the market without compromising on safety (CE and USDA approved).

Local Support: Free remote installation guidance via video call, plus a library of operator training videos in English and Spanish.

Environmentally Friendly: Reduces sludge volume by 60%, cutting landfill fees by $500+/month for a medium plant—plus, dry cake can be sold as low-cost biomass fuel.

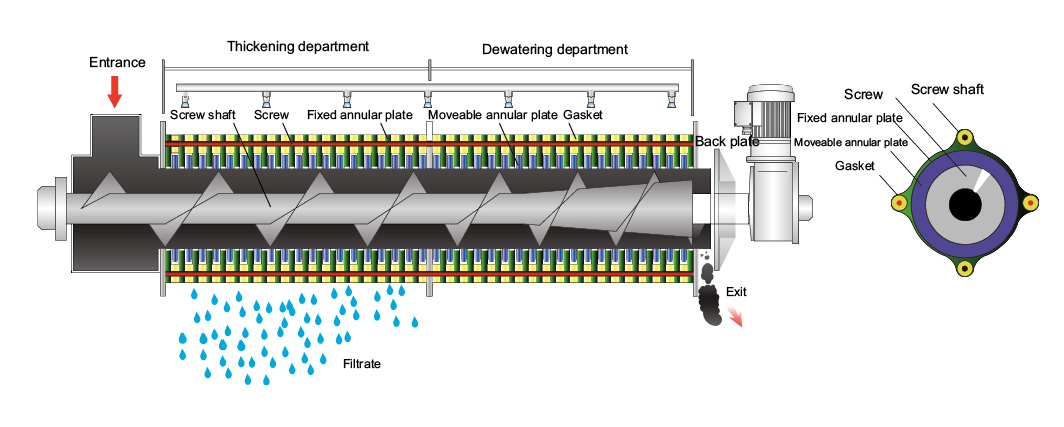

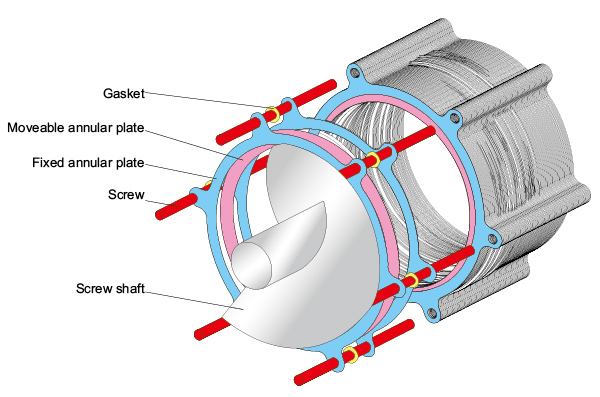

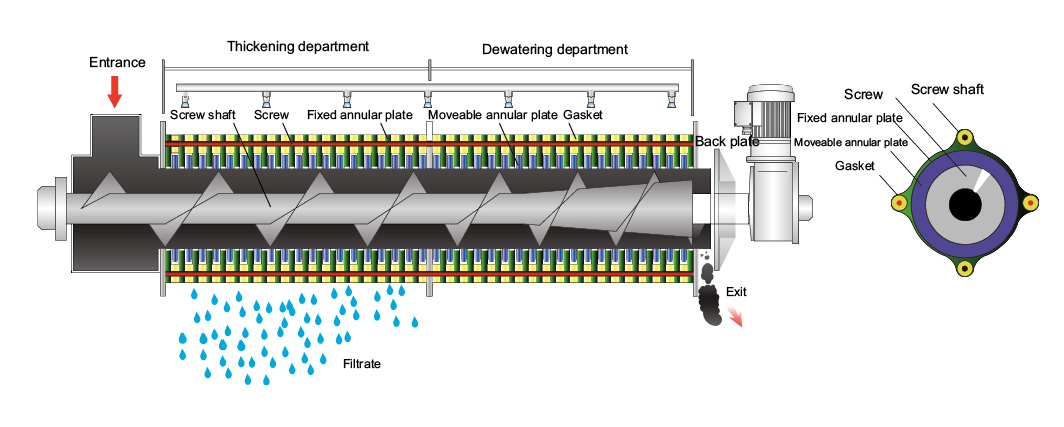

overall structure

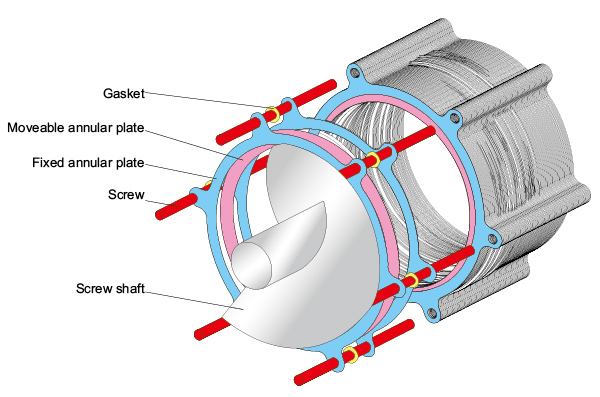

Composition & Working Principle

The multiple fixed rings and moveable rings with the a screw shaft running through compose the main body of the screw filter press dewatering equipment in which there are two sections. The front part is responsible for thickening and the ending part does the dewatering working. It can thicken and dewater sludge in one box. It has gradually taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

After being thickened in the thickening part, the sludge will be transported to the dewatering part . In the course of progress, great pressure has been produced because the filter spacing and screw distance with the clogging of the back platen become smaller and smaller. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

The Integrated Screw Filter Press Dewatering System offers a fully automated and economical approach to sludge treatment. Utilizing advanced screw press technology, the unit performs both thickening and dewatering within a single, simplified workflow, helping reduce energy use and overall operating expenses. Its automated polymer dosing, flocculation process, and sludge cake conveying work in coordination to manage a wide range of sludge types with minimal operator involvement. Engineered to process even challenging materials—such as oily sludge and various industrial wastewater streams—the system is well suited for municipal plants, food-processing facilities, slaughterhouses, and similar applications. Supported by BOEEP’s proven technologies, including its Volute Screw Press and Belt Filter Press solutions, the system delivers strong performance, high reliability, and low maintenance requirements, making it a dependable option in modern sludge dewatering applications.

Frame constructed with polymer-coated carbon steel (abrasion resistance ≥ 500 cycles), cutting material costs by 30% while maintaining structural integrity in wet environments.

Simple single-screw design with only 3 moving parts (screw, motor, and control valve), reducing maintenance costs by 40% compared to multi-screw systems.

Three size options:

0.5m screw (5m³/h capacity) for small butcher shops

1m screw (10m³/h) for medium slaughterhouses

1.5m screw (15m³/h) for large processing plants

8mm-pitch screw with 45° lead angle compresses fatty sludge efficiently, achieving 30-35% solids content—tested on chicken processing waste (high fat) and beef trimming sludge (high protein).

Anti-clogging filter screen (0.2mm pores) with 316 stainless steel mesh traps bone fragments and connective tissue, reducing screen replacements from monthly to quarterly.

Epoxy coating (500μm thickness) on internal components withstands lactic acid and urea in slaughter wastewater, extending service life by 20%.

Plug-and-play design: Connect to your existing sludge pump (1.5kW or higher) using standard flange fittings—no custom piping required, installation completed in 2 hours.

Automatic reverse function: Activates when pressure exceeds 3 bar, rotating the screw backward for 30 seconds to clear minor clogs—no production downtime.

Slaughterhouse Waste: Processes primary sludge from carcass washing, offal tanks, and rendering plants—handle up to 15% solids input efficiently.

Food Waste Recycling: Converts poultry litter, pork fat trimmings, and beef blood sludge into dry cake for biogas production (35% solids) or animal feed additives (40% solids).

Small-Scale Operations: Ideal for family-owned slaughterhouses (processing <500 head/day) and regional plants in countries like Brazil, where cost efficiency is critical.

Affordable Entry Point: Starting at $12,000—lower than any certified slaughter waste dewatering solution on the market without compromising on safety (CE and USDA approved).

Local Support: Free remote installation guidance via video call, plus a library of operator training videos in English and Spanish.

Environmentally Friendly: Reduces sludge volume by 60%, cutting landfill fees by $500+/month for a medium plant—plus, dry cake can be sold as low-cost biomass fuel.

overall structure

Composition & Working Principle

The multiple fixed rings and moveable rings with the a screw shaft running through compose the main body of the screw filter press dewatering equipment in which there are two sections. The front part is responsible for thickening and the ending part does the dewatering working. It can thicken and dewater sludge in one box. It has gradually taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

After being thickened in the thickening part, the sludge will be transported to the dewatering part . In the course of progress, great pressure has been produced because the filter spacing and screw distance with the clogging of the back platen become smaller and smaller. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.