Is food industry sludge’s high organic content causing drainage issues? Our Laser-Cut Volute Filter Press uses advanced laser-cut technology to create 0.1mm-wide filtration slots, precisely trapping fine food particles like starch and protein while letting water pass through. The volute screw design applies uniform pressure across the entire filter bed, squeezing out more water than traditional presses—all while meeting strict food-grade hygiene standards.

| Availability: | |

|---|---|

| Quantity: | |

MYDL203

BOEEP

MYDL

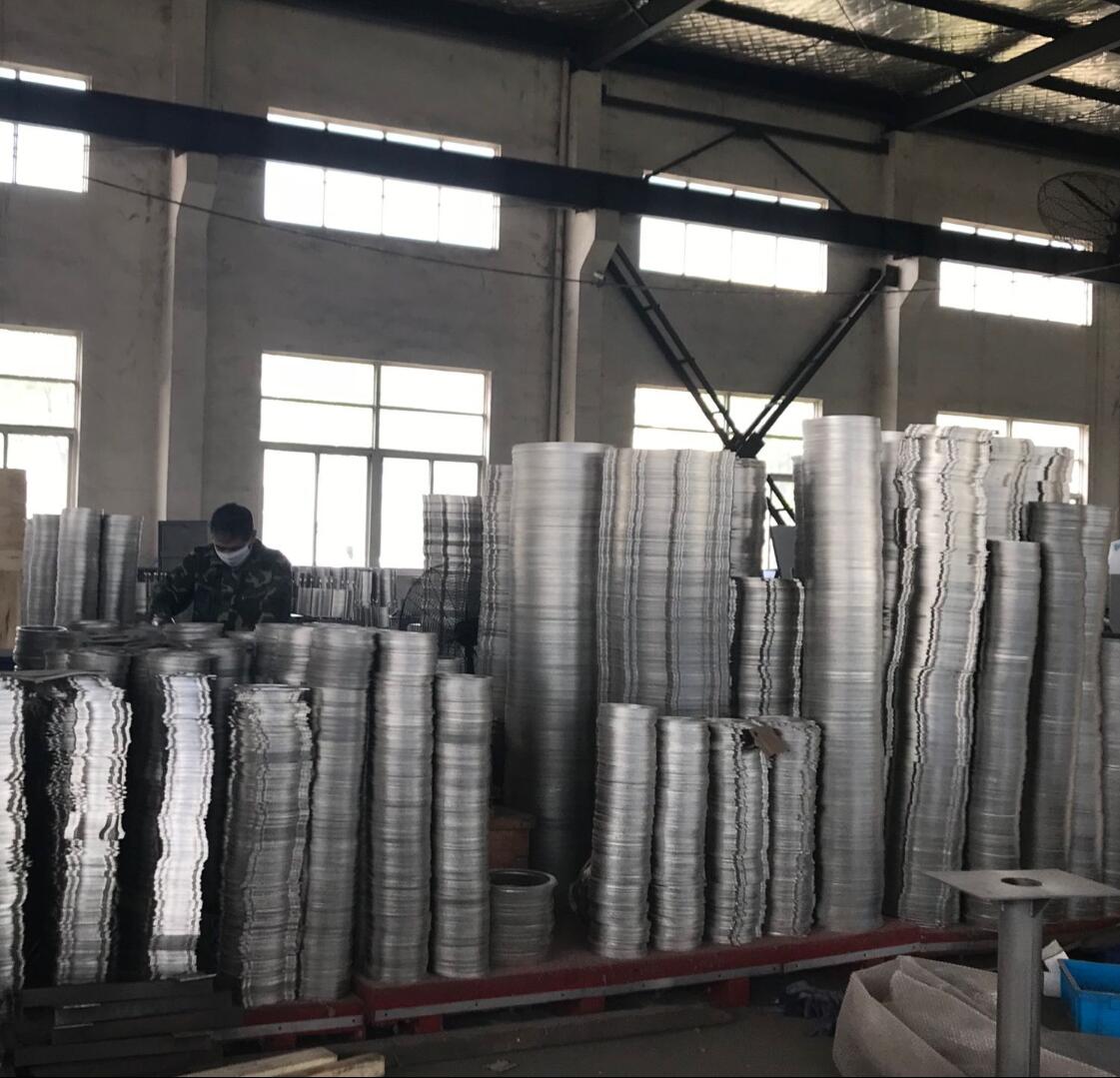

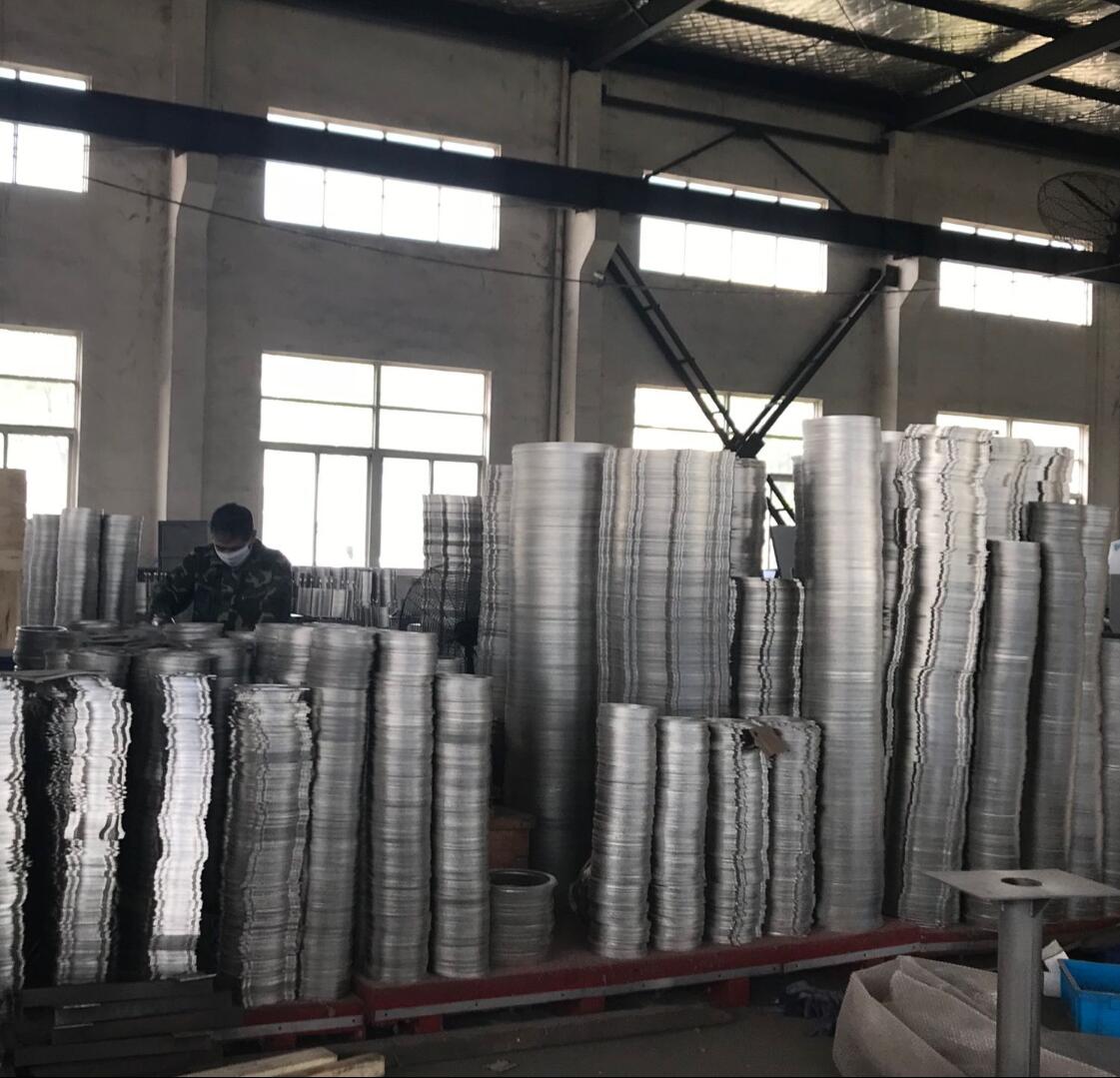

Filter plates made via 500W fiber laser cutting, achieving slot accuracy of ±0.05mm—critical for capturing 50μm+ food particles that clog standard screens.

Volute screw with variable-pitch threads (150mm at inlet, 50mm at outlet) increases compression gradually, preventing channeling and ensuring 95% water extraction from dairy sludge.

All wetted parts: 316L stainless steel (passivated to reduce surface roughness), certified by NSF/ANSI 61 for drinking water contact and EU 10/2011 for food contact.

Surface finish: Ra ≤ 0.8μm (mirror-like), making it easy to clean and resistant to biofilm formation—essential for audits by companies like Nestlé and AB InBev.

Processes 10m³/h of sludge, producing cake with 45% solids content (dairy sludge) to 50% (brewery spent grains)—ideal for anaerobic digesters requiring high-solid feedstock.

Low noise operation (≤75dB), achieved through sound-insulated housing and precision-balanced screw—safe for plants located near residential areas (e.g., urban breweries in Portland, OR).

Dairy Processing: Handles whey permeate sludge (high lactose), cheese brine waste, and milk solids from pasteurization—proven in Dean Foods and Danone facilities.

Beverage Plants: Dewaters spent grains (beer production), fruit pulps (juice concentrate), and yeast residues (wine making), reducing disposal costs by 40%.

Meat & Poultry: Processes blood plasma, rendered fat, and protein slurry from deboning lines—output cake is suitable for pet food production (with 40%+ solids).

Hygiene First: The only press in its class with both FDA and BRCGS certifications—critical for export to markets with strict food safety laws.

Precision Engineering: Laser-cut components fit together with 0.1mm tolerance, reducing leaks by 90% compared to conventionally manufactured presses (common issue with sticky food sludges).

Zero Waste Promise: Our team helps you develop byproduct recovery plans—for example, turning potato processing sludge into fertilizer pellets sold at $80/ton.

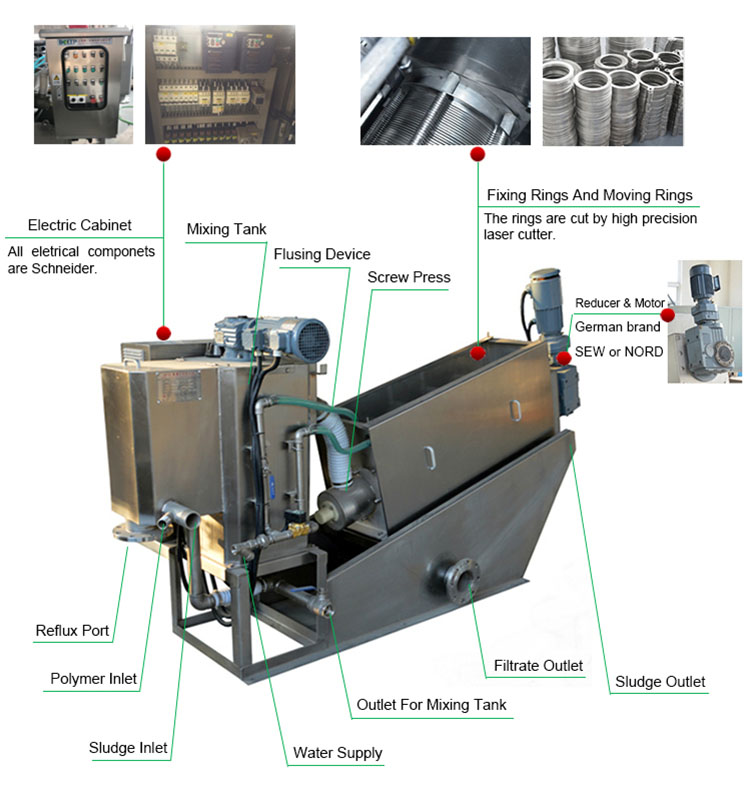

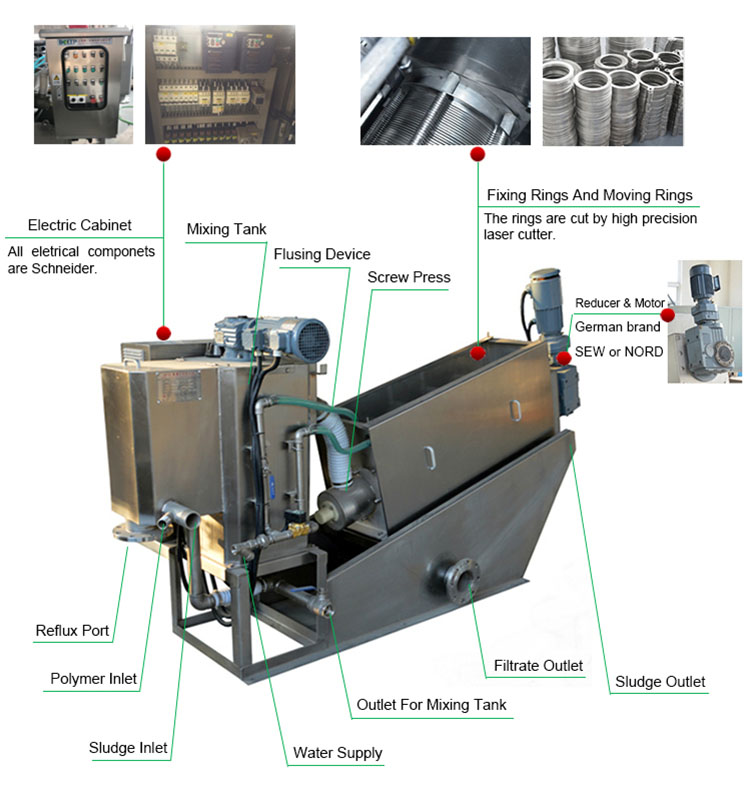

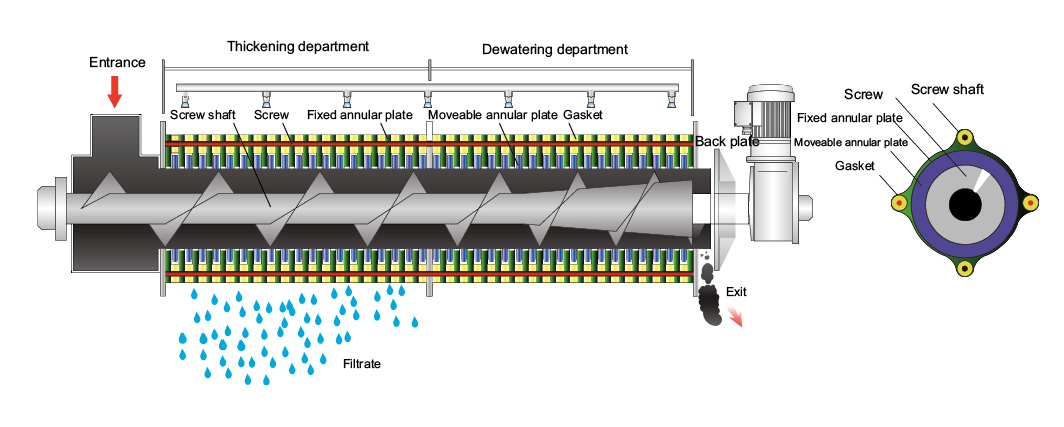

Overall Structure

Component Display

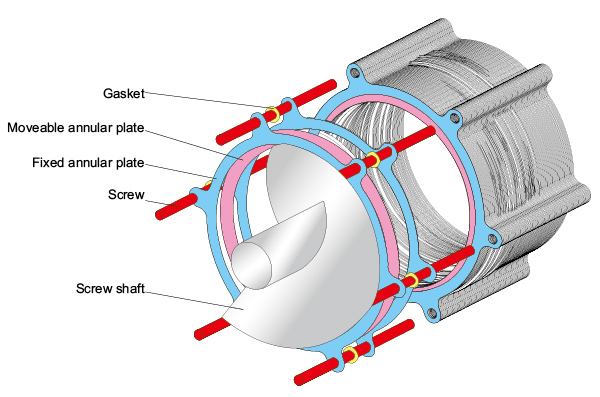

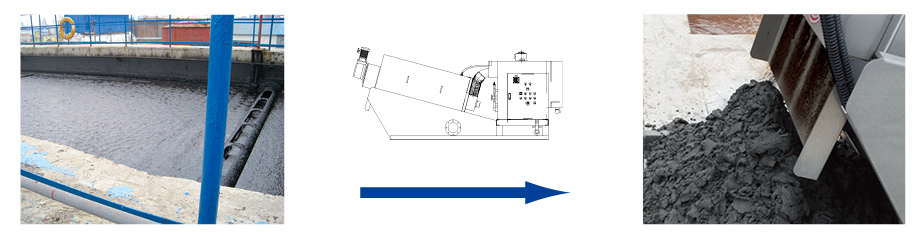

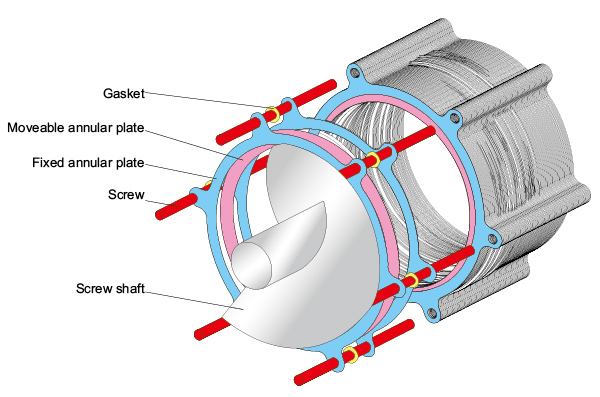

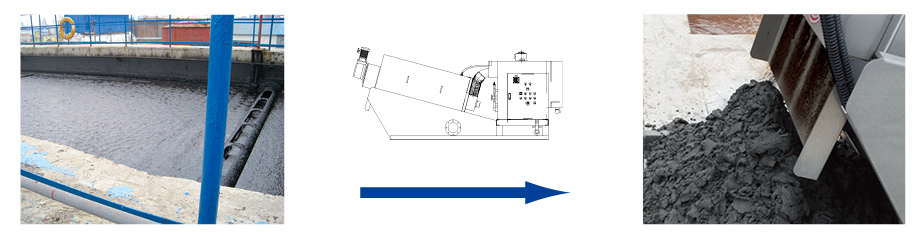

The main body of volute sludge dewatering is made of multiple fixed ring and moveable ring with the screw shaft running through it. The front part is concentrating section and the ending part is dewatering section. It can concentrate and dewater sludge in one box and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

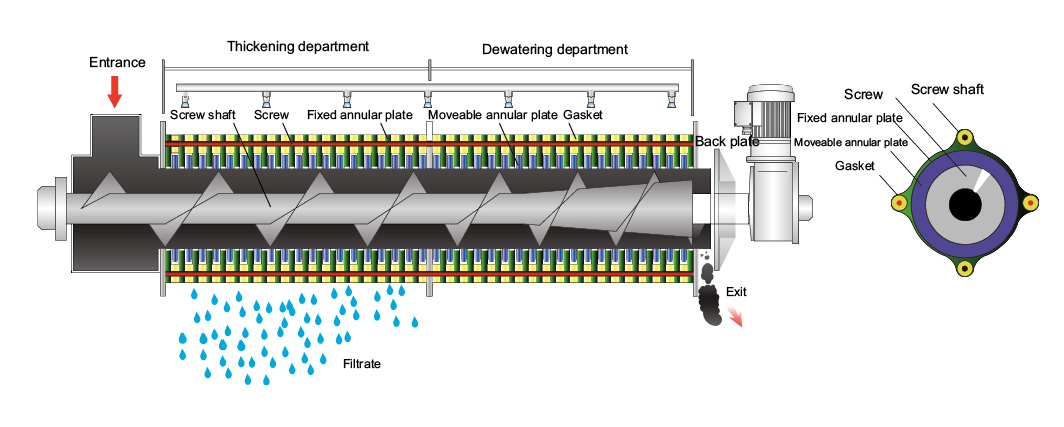

Working Principle

Sludge will be transported to the dewatering part after being thickened in the concentrating section. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance with the block of the back platen. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Function

Innovative structure design makes it possible that the device can be used for all kinds of sludge with high or low density, especially the sludge with oil, and it can be named the invincible opponent to dewater the sludge with oil.

Model Selection

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |

Filter plates made via 500W fiber laser cutting, achieving slot accuracy of ±0.05mm—critical for capturing 50μm+ food particles that clog standard screens.

Volute screw with variable-pitch threads (150mm at inlet, 50mm at outlet) increases compression gradually, preventing channeling and ensuring 95% water extraction from dairy sludge.

All wetted parts: 316L stainless steel (passivated to reduce surface roughness), certified by NSF/ANSI 61 for drinking water contact and EU 10/2011 for food contact.

Surface finish: Ra ≤ 0.8μm (mirror-like), making it easy to clean and resistant to biofilm formation—essential for audits by companies like Nestlé and AB InBev.

Processes 10m³/h of sludge, producing cake with 45% solids content (dairy sludge) to 50% (brewery spent grains)—ideal for anaerobic digesters requiring high-solid feedstock.

Low noise operation (≤75dB), achieved through sound-insulated housing and precision-balanced screw—safe for plants located near residential areas (e.g., urban breweries in Portland, OR).

Dairy Processing: Handles whey permeate sludge (high lactose), cheese brine waste, and milk solids from pasteurization—proven in Dean Foods and Danone facilities.

Beverage Plants: Dewaters spent grains (beer production), fruit pulps (juice concentrate), and yeast residues (wine making), reducing disposal costs by 40%.

Meat & Poultry: Processes blood plasma, rendered fat, and protein slurry from deboning lines—output cake is suitable for pet food production (with 40%+ solids).

Hygiene First: The only press in its class with both FDA and BRCGS certifications—critical for export to markets with strict food safety laws.

Precision Engineering: Laser-cut components fit together with 0.1mm tolerance, reducing leaks by 90% compared to conventionally manufactured presses (common issue with sticky food sludges).

Zero Waste Promise: Our team helps you develop byproduct recovery plans—for example, turning potato processing sludge into fertilizer pellets sold at $80/ton.

Overall Structure

Component Display

The main body of volute sludge dewatering is made of multiple fixed ring and moveable ring with the screw shaft running through it. The front part is concentrating section and the ending part is dewatering section. It can concentrate and dewater sludge in one box and has taken place of the traditional filter clothes and centrifugal filtration method for its distinctive filter model.

Working Principle

Sludge will be transported to the dewatering part after being thickened in the concentrating section. In the advancing process, great pressure has been produced because of the gradually decreasing filter spacing and screw distance with the block of the back platen. Then the volume decreases continuously, and the purpose of fully dewatering will be achieved.

Function

Innovative structure design makes it possible that the device can be used for all kinds of sludge with high or low density, especially the sludge with oil, and it can be named the invincible opponent to dewater the sludge with oil.

Model Selection

| Model | DS Sludge treating capacity | Sludge treating capacity | ||||

| 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| MYDL101 | 5-7 kg/h | ~0.5m³/h | ~0.25 m³/h | ~0.2 m³/h | ~0.15m³/h | ~0.14 m³/h |

| MYDL131 | 10-14 kg/h | ~1 m³/h | ~0.5 m³/h | ~0.4 m³/h | ~0.3 m³/h | ~0.28 m³/h |

| MYDL201 | 15-20 kg/h | ~1.5m³/h | ~0.75 m³/h | ~0.6 m³/h | ~0.5m³/h | ~0.4 m³/h |

| MYDL202 | 30-40 kg/h | ~3 m³/h | ~1.5 m³/h | ~1.2 m³/h | ~1 m³/h | ~0.8m³/h |

| MYDL203 | 45-60 kg/h | ~4.5 m³/h | ~2.25 m³/h | ~1.8 m³/h | ~1.5 m³/h | ~1.2 m³/h |

| MYDL301 | 50-70 kg/h | ~5 m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4 m³/h |

| MYDL302 | 100-140 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.8 m³/h |

| MYDL303 | 150-210 kg/h | ~15 m³/h | ~7.5 m³/h | ~6m³/h | ~4.5 m³/h | ~4.2 m³/h |

| MYDL304 | 200-280 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~5.6m³/h |

| MYDL351 | 100-120 kg/h | ~10 m³/h | ~5m³/h | ~4 m³/h | ~3 m³/h | ~2.4 m³/h |

| MYDL352 | 200-240 kg/h | ~20 m³/h | ~10 m³/h | ~8 m³/h | ~6m³/h | ~4.8 m³/h |

| MYDL353 | 300-360 kg/h | ~30 m³/h | ~15 m³/h | ~12 m³/h | ~9 m³/h | ~7.2m³/h |

| MYDL354 | 400-480 kg/h | ~40 m³/h | ~20 m³/h | ~16 m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL401 | 130-160 kg/h | ~13 m³/h | ~6.5 m³/h | ~5 m³/h | ~4 m³/h | ~3.2 m³/h |

| MYDL402 | 260-320 kg/h | ~26 m³/h | ~13 m³/h | ~10 m³/h | ~8 m³/h | ~6.4 m³/h |

| MYDL403 | 390-480 kg/h | ~39 m³/h | ~19.5 m³/h | ~15m³/h | ~12 m³/h | ~9.6 m³/h |

| MYDL404 | 520-640 kg/h | ~52 m³/h | ~26 m³/h | ~20 m³/h | ~16m³/h | ~12.8m³/h |