| Availability: | |

|---|---|

| Quantity: | |

MYDL351

BOEEP

MYDL

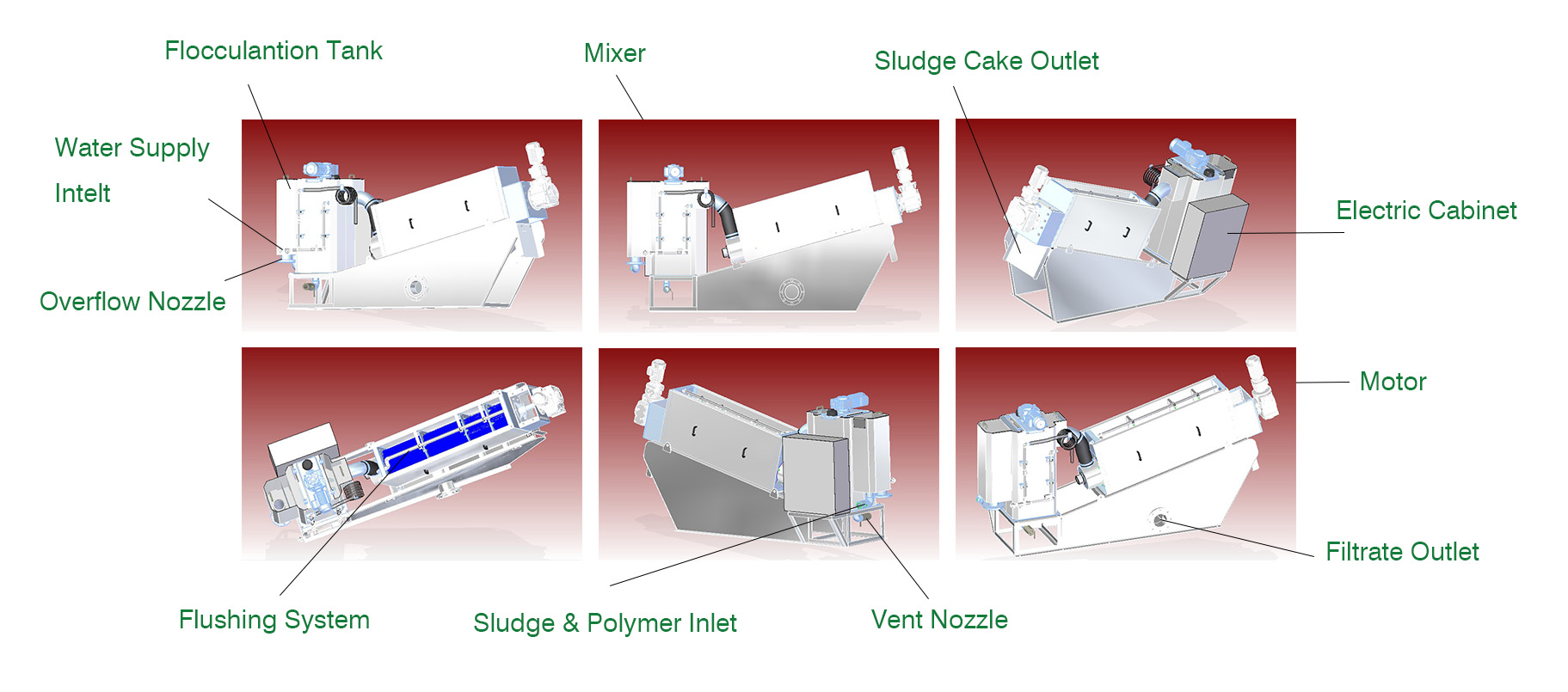

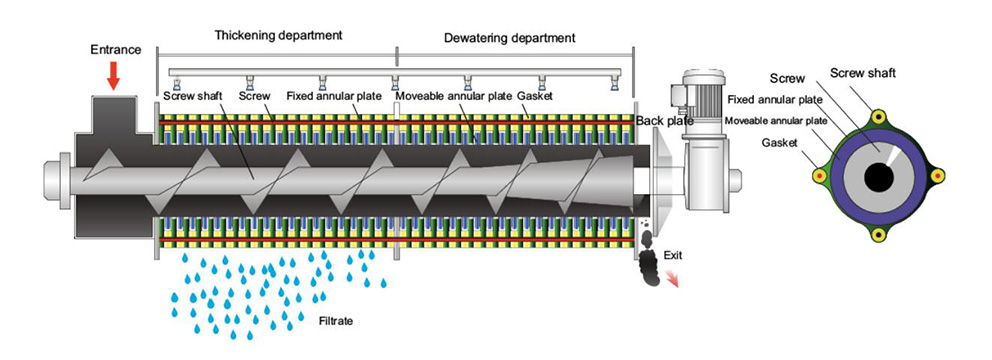

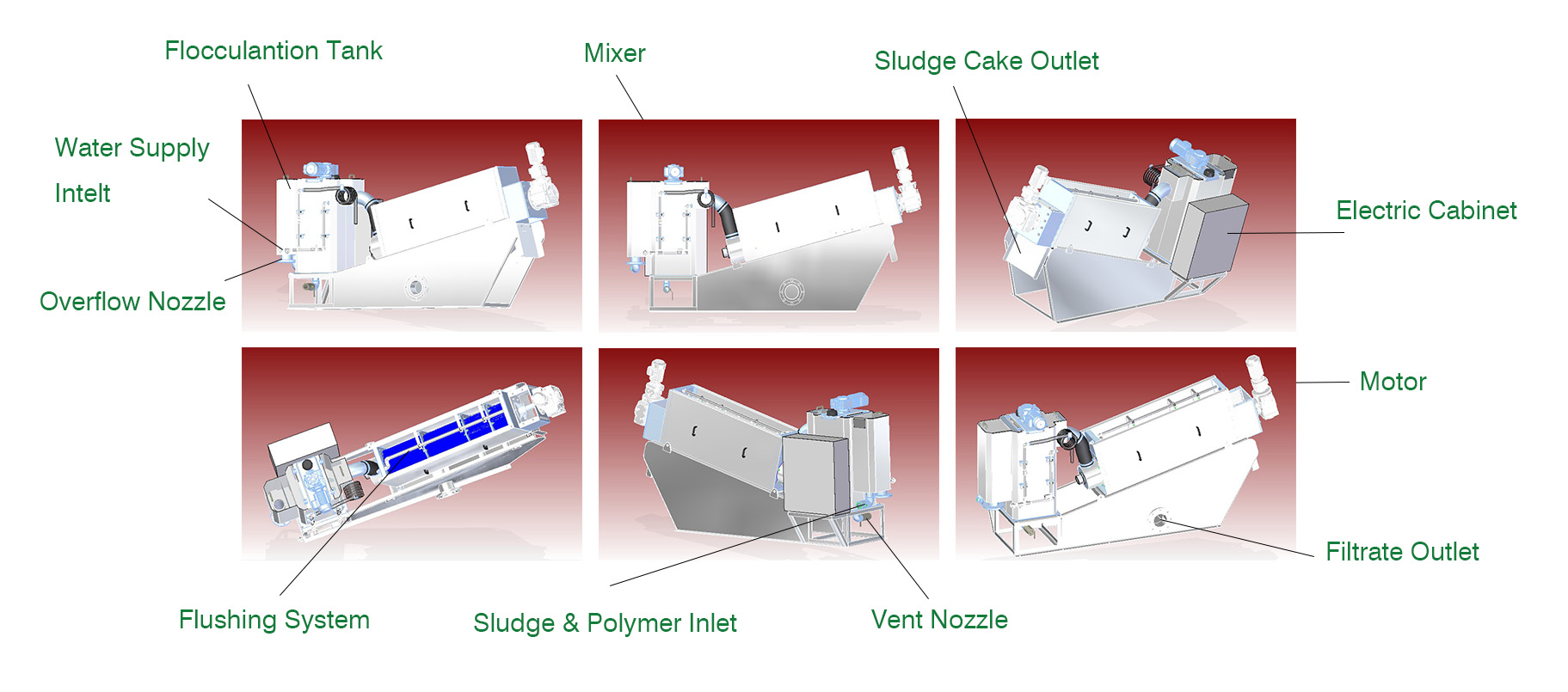

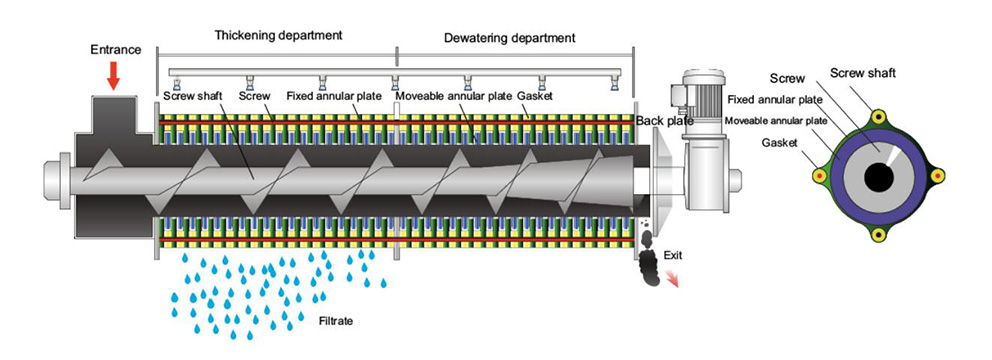

Structure of Volute Press Sludge Dewatering Machine

Exceptional Energy Efficiency with Minimal Operating Costs

Achieve up to 70% reduction in energy consumption, supported by a low-power main motor (2.2–7.5 kW) that eliminates the need for high-pressure pumps and their ancillary power units. Furthermore, the system operates without flushing water, completely removing related water consumption and costs.

Flocculant Savings

Optimized flow paths enhance contact between sludge and polymer, improving flocculation efficiency and enabling a 15–30% reduction in PAM usage.

Higher Sludge Recovery & Drier Cake Output

Multi-stage pressurization combined with an adjustable back-pressure plate establishes a controlled pressure profile, resulting in solid cake with 20–25% dry solids content. This significantly reduces sludge volume, lowering both transport and disposal expenses.

Fully Automated Operation & Low Maintenance

An integrated PLC control system enables one-touch start/stop, adaptive pressure adjustment, overload protection, and remote monitoring—ensuring reliable, unattended operation.

Screen-Free Design

The unique volute structure eliminates the need for filter screens, preventing clogging issues common in belt or screw presses. This design removes the need for routine rinsing and cuts maintenance efforts by over 80%.

Robust Construction & Broad Adaptability

The core screw shaft is manufactured from 316L stainless steel and coated with tungsten carbide for superior wear resistance. Its lifespan exceeds that of conventional components by more than three times, even under harsh, abrasive conditions such as highly corrosive industrial sludge.

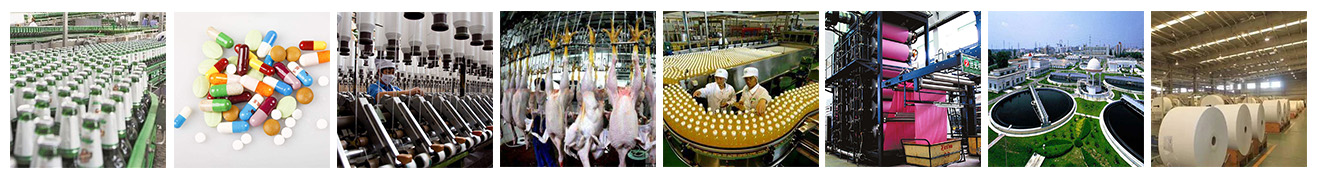

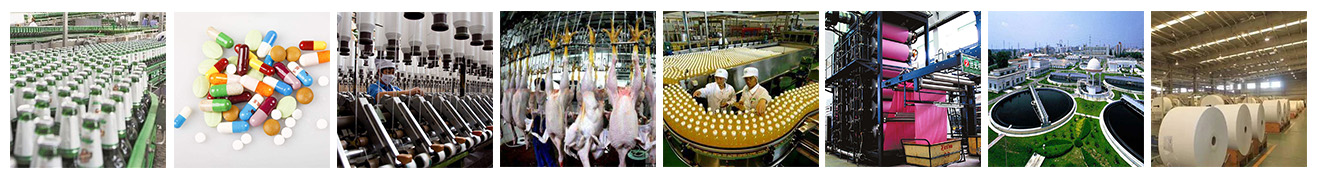

Application of Volute Press Sludge Dewatering Machine

| Tobacco industry wastewater treatment | Brewery/wine process wastewater | Anaerobic digested sludge/aerobic sludge |

| Hospital sewage | Landfill leachate/refuse leachate/percolated fluid | Biotechnology/bioengineering/biological engineering/bioengineering |

| Machining wastewater | Printing and dyeing | Water purification industry |

| Chemical wastewater | Petrochemical industry/oily sludge | Eletroplating industry |

| Paper making | Animal slaughter/animal butcher | Recycled water/reclaimed water |

| Refuse processing plant/garbage proposal | Coal chemical industry | Cooking wastewater/kitchen waste |

| Industrial wastewater | Animal husbandry/livestock industry/livestock breeding | Textile |

| Food industry | Municipal wastewater/domestic wastewater/urban sewage treatment | Municipal wastewater/domestic wastewater/urban sewage treatment |

Our dewatering equipment provides targeted solutions for challenging sludge across multiple industries:

Municipal Wastewater: Effective on excess activated, primary, and mixed sludge.

Industrial Sludge: Ideal for handling:

Organic sludge from food processing (e.g., slaughterhouse, brewing, dairy, starch).

Chemical and high-concentration organic sludge from the chemical and pharmaceutical industries.

Pulp sludge and flotation tailings from paper manufacturing.

Metal hydroxide sludge from electroplating and metal processing (custom material options offered).

Traditional Pain Point: High Operating Costs

Our Breakthrough: Zero freshwater consumption for flushing and remarkably low energy demand translate into direct, substantial savings on your utility bills.

Traditional Pain Point: Unreliable Cake Dryness

Our Breakthrough: Achieve consistently high solids content, enabling cost-effective compliance with disposal methods like composting, incineration, or landfill.

Traditional Pain Point: Clogging & Downtime

Our Breakthrough: The innovative screenless design eradicates the root cause of clogging, virtually eliminating related maintenance and downtime.

Traditional Pain Point: Chemical Waste

Our Breakthrough: Superior sludge-polymer mixing technology maximizes chemical efficiency, reducing polymer consumption and treatment costs.

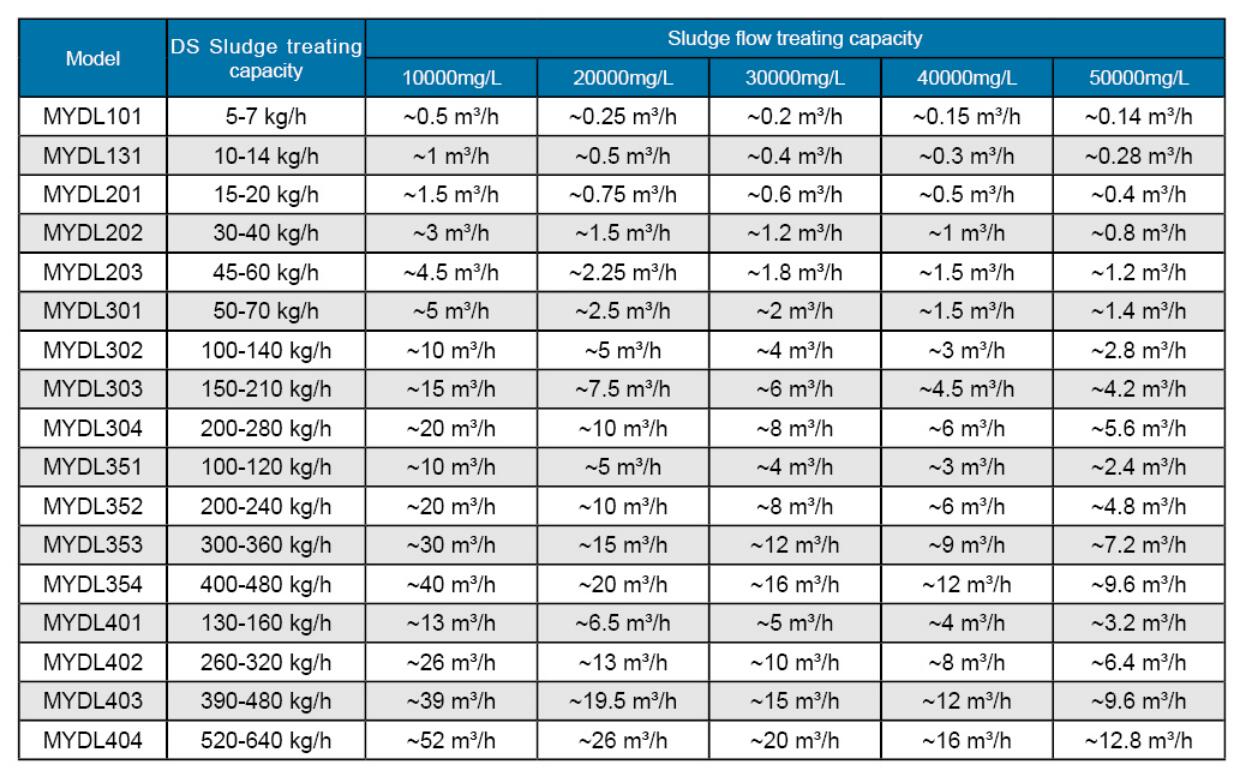

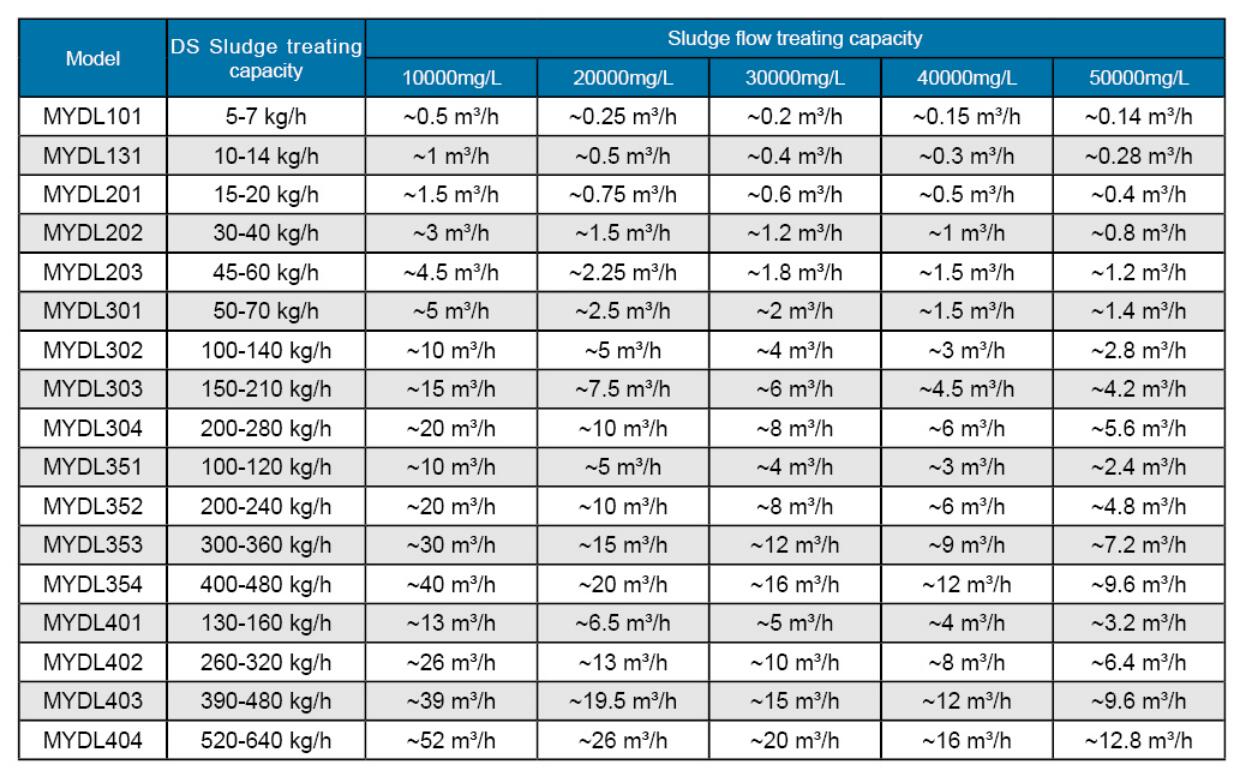

Model Choice of Volute Press Sludge Dewatering Machine

Packing Site of Volute Press Sludge Dewatering

Structure of Volute Press Sludge Dewatering Machine

Exceptional Energy Efficiency with Minimal Operating Costs

Achieve up to 70% reduction in energy consumption, supported by a low-power main motor (2.2–7.5 kW) that eliminates the need for high-pressure pumps and their ancillary power units. Furthermore, the system operates without flushing water, completely removing related water consumption and costs.

Flocculant Savings

Optimized flow paths enhance contact between sludge and polymer, improving flocculation efficiency and enabling a 15–30% reduction in PAM usage.

Higher Sludge Recovery & Drier Cake Output

Multi-stage pressurization combined with an adjustable back-pressure plate establishes a controlled pressure profile, resulting in solid cake with 20–25% dry solids content. This significantly reduces sludge volume, lowering both transport and disposal expenses.

Fully Automated Operation & Low Maintenance

An integrated PLC control system enables one-touch start/stop, adaptive pressure adjustment, overload protection, and remote monitoring—ensuring reliable, unattended operation.

Screen-Free Design

The unique volute structure eliminates the need for filter screens, preventing clogging issues common in belt or screw presses. This design removes the need for routine rinsing and cuts maintenance efforts by over 80%.

Robust Construction & Broad Adaptability

The core screw shaft is manufactured from 316L stainless steel and coated with tungsten carbide for superior wear resistance. Its lifespan exceeds that of conventional components by more than three times, even under harsh, abrasive conditions such as highly corrosive industrial sludge.

Application of Volute Press Sludge Dewatering Machine

| Tobacco industry wastewater treatment | Brewery/wine process wastewater | Anaerobic digested sludge/aerobic sludge |

| Hospital sewage | Landfill leachate/refuse leachate/percolated fluid | Biotechnology/bioengineering/biological engineering/bioengineering |

| Machining wastewater | Printing and dyeing | Water purification industry |

| Chemical wastewater | Petrochemical industry/oily sludge | Eletroplating industry |

| Paper making | Animal slaughter/animal butcher | Recycled water/reclaimed water |

| Refuse processing plant/garbage proposal | Coal chemical industry | Cooking wastewater/kitchen waste |

| Industrial wastewater | Animal husbandry/livestock industry/livestock breeding | Textile |

| Food industry | Municipal wastewater/domestic wastewater/urban sewage treatment | Municipal wastewater/domestic wastewater/urban sewage treatment |

Our dewatering equipment provides targeted solutions for challenging sludge across multiple industries:

Municipal Wastewater: Effective on excess activated, primary, and mixed sludge.

Industrial Sludge: Ideal for handling:

Organic sludge from food processing (e.g., slaughterhouse, brewing, dairy, starch).

Chemical and high-concentration organic sludge from the chemical and pharmaceutical industries.

Pulp sludge and flotation tailings from paper manufacturing.

Metal hydroxide sludge from electroplating and metal processing (custom material options offered).

Traditional Pain Point: High Operating Costs

Our Breakthrough: Zero freshwater consumption for flushing and remarkably low energy demand translate into direct, substantial savings on your utility bills.

Traditional Pain Point: Unreliable Cake Dryness

Our Breakthrough: Achieve consistently high solids content, enabling cost-effective compliance with disposal methods like composting, incineration, or landfill.

Traditional Pain Point: Clogging & Downtime

Our Breakthrough: The innovative screenless design eradicates the root cause of clogging, virtually eliminating related maintenance and downtime.

Traditional Pain Point: Chemical Waste

Our Breakthrough: Superior sludge-polymer mixing technology maximizes chemical efficiency, reducing polymer consumption and treatment costs.

Model Choice of Volute Press Sludge Dewatering Machine

Packing Site of Volute Press Sludge Dewatering