Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

Have you ever wondered how industries efficiently manage sludge? Screw press dewatering is a game-changing technology that simplifies this process.

In various sectors, from wastewater treatment to food processing, effective dewatering is crucial. It reduces waste volume and lowers disposal costs. In this article, you’ll learn how screw presses work, their benefits, and why they are essential for modern sludge management.

A screw press is a mechanical device designed for dewatering sludge and other waste materials. The core mechanism relies on a rotating screw housed within a cylindrical screen. As the screw turns, it moves the material forward while simultaneously squeezing out liquid through the screen openings. This process is known as screw press dewatering.

Key components of a screw press include:

● Screw: The central element that drives the dewatering process. Its design allows for efficient movement and compression of the sludge.

● Cylinder: The outer casing that contains the screw and provides structural integrity. It also supports the screen.

● Screen: A perforated surface that allows water to escape while retaining solid particles. Its aperture size is typically less than 0.5 mm, ensuring effective filtration.

The design of a screw press is crucial for its performance. The gradual narrowing of the screw’s pitch increases pressure on the sludge, enhancing water removal. This mechanism is particularly effective in industries where managing large volumes of liquid waste is essential.

Screw presses come in various designs, each tailored for specific applications. Understanding these variations can help industries choose the right equipment for their needs. Here are some common types:

● Single-Screw Press: The most basic design, suitable for general sludge dewatering.

● Multi-Disc Screw Press: A more advanced version featuring multiple discs that enhance the dewatering process. This type is particularly beneficial for oily or greasy sludges, as it minimizes clogging and maximizes efficiency.

The multi-disc screw press is a standout in the world of screw press dewatering. It features a series of discs that create a self-cleaning mechanism. This design allows for continuous operation, even when processing challenging materials.

Benefits of Multi-Disc Screw Presses:

● Reduced Clogging: The self-cleaning action prevents the buildup of materials, making it ideal for greasy sludges.

● Higher Efficiency: It can achieve greater dewatering rates compared to traditional single-screw presses.

● Lower Maintenance: With fewer blockages, maintenance requirements decrease significantly, saving time and costs.

Screw presses are widely adopted across various sectors due to their efficiency and reliability. Here are some industries where they play a vital role:

Industry | Application |

Municipal Wastewater Treatment | Effective in reducing sludge volume for disposal. |

Food and Beverage | Handles organic residues and fats efficiently. |

Agriculture | Processes manure into nutrient-rich fertilizers. |

Plastic Recycling | Dewaters plastic films, improving recycling efficiency. |

These applications highlight the versatility of screw presses. By choosing the right type, industries can optimize their waste management processes and contribute to sustainability efforts.

Screw press dewatering has become a standard practice in many sectors, thanks to its ability to reduce waste volume and improve operational efficiency. Understanding the functionality and types of screw presses is essential for any business looking to enhance its waste management strategies.

Screw press dewatering is a systematic process that efficiently removes water from sludge. Understanding the steps involved can help industries optimize their operations. Here’s a breakdown of the mechanism.

Before dewatering, sludge conditioning is essential. This process prepares the sludge for more effective water removal.

● Importance of Conditioning: Conditioning helps break down the sludge structure, making it easier to dewater.

● Role of Polymers: Adding polymers enhances dewatering efficiency. They bind with the solids, improving flocculation and making it easier for the screw press to separate water from solids.

Once conditioned, the sludge enters the gravity drainage zone of the screw press. Here, gravity plays a vital role.

● Initial Water Removal: Gravity helps in the preliminary separation of water from the sludge. This initial phase reduces the load on the screw press.

● Wider Pitch Section: The design features a wider pitch section of the screw, allowing more water to escape before the compression phase begins.

After gravity drainage, the sludge moves into the compression and dewatering zone. This is where the real magic happens.

● Compression Mechanism: As the screw rotates, it compresses the sludge against the cylindrical screen. This pressure forces water out through the screen openings.

● Narrowing Pitch and Pressure Increase: The screw's pitch narrows, which increases pressure on the sludge. This design is crucial for maximizing water removal.

● Self-Cleaning Feature: Alternating fixed and moving rings within the screw help maintain efficiency. They prevent clogging by cleaning the screen during operation.

Finally, the dewatered sludge, now referred to as cake, is discharged. This step is critical for completing the dewatering process.

● Final Compression and Discharge: The last phase involves compressing the sludge cake to achieve optimal dryness before it’s discharged.

● Characteristics of Dewatered Cake: Typically, the dewatered cake has a solids content ranging from 15% to 25%. This concentration is ideal for further processing or disposal.

Managing the liquid extracted during the dewatering process is equally important.

● Collection and Reuse: The filtrate, or liquid, can often be treated and reused within the facility. This practice not only conserves water but also reduces overall operational costs.

● Impact on Environmental Compliance: Proper filtrate management ensures compliance with environmental regulations, further enhancing the sustainability of the operation.

When considering screw press dewatering, understanding key specifications is crucial. These specifications determine performance, efficiency, and overall effectiveness. Here’s a closer look at the essential factors.

Throughput capacity refers to the volume of sludge a screw press can process within a specific time frame.

● Definition: It is typically measured in cubic meters per hour (m³/h) or tons per hour (TPH).

● Importance in Sizing the Press: Knowing the required throughput helps in selecting the right screw press for your operation. An undersized press can lead to inefficiencies, while an oversized unit may incur unnecessary costs.

The solids loading rate indicates how much solid material is fed into the screw press.

● Impact on Operational Efficiency: A higher solids loading rate can enhance throughput but may also affect dewatering efficiency. Balancing this rate is key to maintaining optimal performance.

● Considerations: Operators should monitor the loading rate to avoid overloading, which can lead to clogging and reduced effectiveness.

The screw diameter and speed are vital for the performance of screw press dewatering.

● Impact on Performance: A larger diameter screw can handle more material, whereas the speed affects how quickly the sludge is processed.

● Energy Consumption: Higher speeds may increase energy use, so finding the right balance is essential for cost-effective operations.

Typically, screw speeds range from 0.2 to 2 RPM.

● Discussion: Running at lower speeds often results in better dewatering, as it allows for more thorough compression and drainage. Conversely, higher speeds can lead to faster processing but may reduce the quality of dewatering.

● Benefits: Operating within this optimal range enhances performance while minimizing energy consumption and wear on the equipment.

The final cake solids content is a critical performance metric in screw press dewatering.

● Expected Ranges: Typically, the solids content of the dewatered cake ranges from 15% to 25%. This level of dryness is ideal for disposal or further processing.

● Performance Metrics: Monitoring the solids content helps assess the efficiency of the dewatering process. Higher solids content indicates effective water removal, while lower levels may signal issues with the dewatering system.

Specification | Typical Value |

Throughput Capacity | 5 to 50 m³/h |

Solids Loading Rate | Up to 10% solids |

Screw Diameter | 100 mm to 400 mm |

Screw Speed | 0.2 to 2 RPM |

Final Cake Solids Content | 15% to 25% solids |

Understanding these key specifications allows industries to optimize their screw press dewatering systems. By carefully considering throughput capacity, solids loading rate, screw diameter and speed, and final cake solids content, businesses can enhance efficiency and reduce operational costs.

Screw press dewatering offers numerous advantages that make it a preferred choice in various industries. From energy efficiency to versatility, understanding these benefits can help businesses optimize their waste management processes.

One of the standout features of screw press dewatering is its energy efficiency.

● Comparison with Other Dewatering Technologies: Compared to traditional methods like belt presses or centrifuges, screw presses consume significantly less energy. This efficiency translates into lower operational costs and reduced environmental impact.

Screw presses are designed for durability and ease of maintenance, which leads to cost savings.

● Reduced Cleaning Time and Labor: The self-cleaning mechanism minimizes the need for frequent manual cleaning. This not only saves time but also reduces labor costs associated with maintenance.

● Low Water Usage: The design of screw presses significantly cuts down on water consumption. The self-cleaning feature allows for effective operation without excessive rinsing, making it environmentally friendly.

The self-cleaning aspect is crucial for operational efficiency.

● Minimizing Water Consumption: By reducing the need for water during cleaning cycles, screw presses can operate more sustainably. This is particularly beneficial in regions where water resources are limited.

Screw presses excel in their ability to process a variety of sludge types.

● Types of Sludges Suitable for Screw Press Dewatering: They can handle municipal wastewater, industrial sludge, and agricultural waste. This versatility makes them suitable for diverse applications across multiple sectors.

Screw presses are particularly effective for challenging materials.

● Effectiveness in Processing Fibrous, Oily, or Greasy Materials: These machines can efficiently process sludges that are fibrous or contain high levels of fats and oils. The design prevents clogging, ensuring consistent performance even with difficult materials.

Advantage | Description |

Energy Efficiency | Lower energy consumption compared to other methods. |

Low Maintenance Costs | Reduced cleaning time and labor requirements. |

Low Water Usage | Self-cleaning design minimizes water needs. |

Versatility | Suitable for various sludge types, including oily ones. |

Screw press dewatering stands out for its energy efficiency, low maintenance requirements, and versatility. These advantages not only enhance operational efficiency but also contribute to sustainability efforts, making it a wise choice for businesses looking to improve their waste management strategies.

When it comes to dewatering sludge, various technologies are available, each with its own strengths and weaknesses. Here, we’ll compare screw press dewatering with high-pressure filter presses, highlighting their key differences and advantages.

Screw presses and high-pressure filter presses are two commonly used methods for sludge dewatering. Understanding their operational differences can help businesses make informed decisions.

● Key Differences in Operation:

○ Screw Press: Operates continuously, using a rotating screw to compress and dewater sludge. This design allows for a steady flow of material, resulting in consistent output.

○ High-Pressure Filter Press: Involves batch processing, where sludge is pumped into a series of plates and frames. The pressure forces water out through filter cloths, creating a cake. This process requires more time due to its batch nature.

● Efficiency:

○ Screw Press: Typically achieves higher throughput with lower energy consumption, making it more efficient for continuous operations.

○ High-Pressure Filter Press: While effective, it may require more energy and labor for operation and maintenance.

When considering the financial aspects, a cost-benefit analysis is crucial.

● Upfront Costs:

○ High-pressure filter presses often have higher initial costs due to their complex design and additional components.

○ Screw presses generally require less capital investment, making them more accessible for many businesses.

● Long-Term Savings:

○ Screw press dewatering typically results in lower operational costs over time due to reduced energy consumption and maintenance requirements.

○ The continuous operation of screw presses can lead to increased efficiency and productivity, further enhancing long-term savings.

One of the standout features of screw presses is their ability to operate continuously, which brings several benefits.

● Benefits of Automated Processes:

○ Continuous operation means less downtime, allowing for consistent sludge processing. This is particularly advantageous for facilities that generate large volumes of sludge.

○ Automation reduces the need for manual intervention, lowering labor costs and minimizing human error.

● Improved Efficiency:

○ By maintaining a steady flow of material, screw presses can optimize the dewatering process. This results in higher solids content in the final cake and better water recovery.

Comparison Factor | Screw Press | High-Pressure Filter Press |

Operation Type | Continuous | Batch |

Energy Consumption | Lower | Higher |

Upfront Costs | Generally lower | Generally higher |

Long-Term Savings | Higher due to efficiency | Lower, due to maintenance |

Labor Requirements | Reduced due to automation | Higher due to manual processes |

Screw press dewatering clearly stands out in terms of efficiency, cost-effectiveness, and operational benefits. By understanding these differences, businesses can choose the technology that best fits their needs and optimize their sludge management processes.

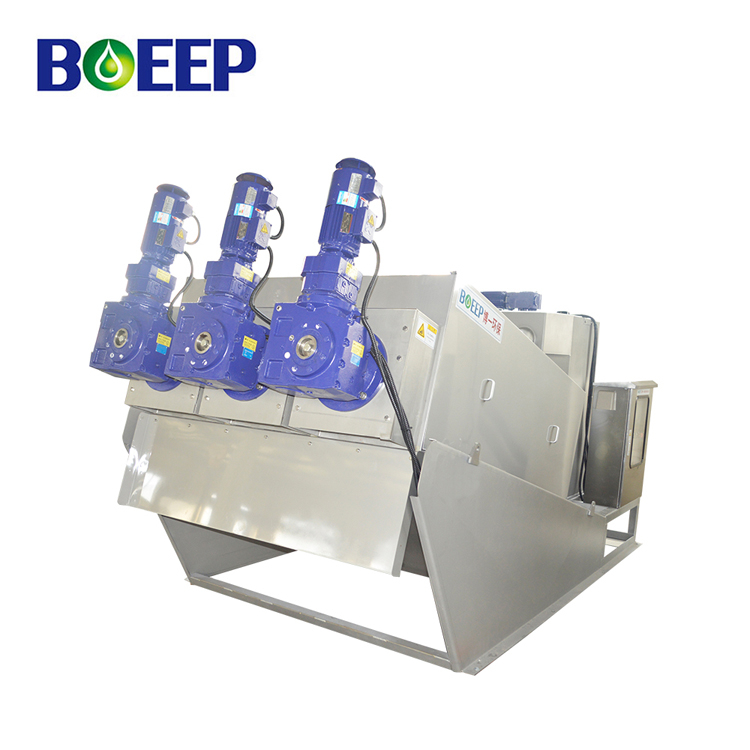

Screw press dewatering is crucial for effective sludge management. It offers high efficiency and lower operational costs. This technology ensures continuous processing, reducing downtime and labor needs. Companies like BOEEP provide innovative screw press solutions that enhance wastewater treatment. Their products are designed for optimal performance and energy efficiency, delivering significant value to users. Consider BOEEP for your sludge management needs and experience the benefits of advanced screw press technology.

A: Screw press dewatering is a method that uses a rotating screw to compress and remove water from sludge, enhancing efficiency in wastewater treatment.

A: A screw press operates by continuously feeding sludge into a chamber where a screw compresses it, allowing water to be expelled through a screen.

A: This technology offers high efficiency, lower energy consumption, and reduced maintenance costs, making it ideal for effective sludge management.

A: Screw press dewatering can process various sludges, including municipal, industrial, and agricultural, ensuring versatility in wastewater treatment.

A: Compared to high-pressure filter presses, screw presses provide continuous operation, lower upfront costs, and improved energy efficiency.

A: Common issues include clogging and inconsistent solids content, which can be mitigated by proper maintenance and regular monitoring of the system.