Views: 0 Author: Site Editor Publish Time: 2026-02-14 Origin: Site

Wastewater treatment is crucial for protecting our environment and public health. Have you ever wondered how large debris is kept from clogging treatment systems? This is where bar screens come into play.

In this article, we will explore what a bar screen is and its vital role in wastewater management. You'll learn about different types, including mechanical and automatic bar screens, and their functions in ensuring efficient treatment processes. Join us as we delve into this essential component of modern sanitation infrastructure.

Bar screens are essential in wastewater treatment, serving a critical role in the initial filtration process. Their design and functionality ensure that large solids are effectively removed from incoming wastewater. Understanding how they work can help facilities optimize their treatment processes.

The basic principle behind a bar screen is straightforward. It consists of vertical bars arranged in parallel, creating gaps that allow water to flow through while blocking larger objects. This simple yet effective design is key to preventing debris from damaging downstream equipment.

● Water Flow: As wastewater enters the bar screen, gravity pulls it downward. The flow rate is designed to ensure that only water passes through the gaps.

● Solid Capture: Larger solids, such as sticks, plastics, and other debris, are unable to pass between the bars. They accumulate on the screen, ready for removal.

The water flow through a bar screen is a carefully managed process. Here’s how it typically unfolds:

1. Inlet Flow: Wastewater enters the bar screen through an inlet channel. The design of this channel helps direct the flow evenly across the screen.

2. Screening Action: As water flows over the bars, it creates a differential pressure. This pressure helps push the water through the gaps while retaining larger solids.

3. Debris Accumulation: Solids that cannot pass through the bars accumulate on the screen surface. This buildup is essential for the screen's effectiveness, as it creates a barrier that further traps additional debris.

The mechanism for capturing and removing large objects is vital for the overall efficiency of wastewater treatment. Here’s how it works:

● Mechanical Bar Screens: In mechanical systems, the accumulated debris is periodically removed using a rake or scraper. This mechanism ensures that the screen remains clear, allowing for continuous operation.

● Automatic Bar Screens: These advanced systems feature automated cleaning processes. They often include rotating brushes or automated rakes that remove debris without manual intervention. This not only saves labor but also maintains optimal screening efficiency.

● Maintenance Considerations: Regular maintenance is crucial for both types of bar screens. Ensuring that the cleaning mechanisms function correctly prevents clogging and enhances the lifespan of the equipment.

Feature | Mechanical Bar Screen | Automatic Bar Screen |

Debris Removal Method | Manual cleaning with rake or scraper | Automated cleaning with brushes or rakes |

Labor Requirements | Higher labor intensity | Lower labor intensity |

Operational Efficiency | Good, but requires regular maintenance | High, with minimal downtime |

Bar screens play a vital role in wastewater treatment by efficiently capturing and removing large solids. Their design and operational principles enable facilities to protect downstream equipment and enhance overall treatment efficiency.

Bar screens are essential components in wastewater treatment, and they come in various types, each with unique functionalities and applications. Understanding these types can help facilities choose the right solution for their needs.

Definition and Functionality

A manual bar screen consists of vertically aligned bars that capture large debris as wastewater flows through. Operators must clean the screen manually, typically using a rake or similar tool.Suitable Applications and Scenarios

● Smaller wastewater treatment facilities

● Situations where flow rates are manageable

● Areas with limited automation budgets

Advantages and Disadvantages

● Advantages:

○ Simple design and installation

○ Low initial cost

● Disadvantages:

○ High labor intensity for maintenance

○ Potential for inconsistent performance due to manual cleaning

Maintenance Requirements and Labor Intensity

Manual bar screens require regular cleaning to remain effective. This can be labor-intensive, as operators must frequently check the screen and remove debris. Regular maintenance is crucial to prevent clogging and ensure optimal performance.

Definition and Functionality

A mechanical bar screen features a series of bars similar to manual screens but includes automated mechanisms for cleaning. These systems often use rakes or scrapers to remove debris automatically.Description of Automated Cleaning Mechanisms

● Rake systems that move along the bars to lift debris

● Scraper mechanisms that push collected solids into a discharge area

Suitable Applications and Scenarios

● Medium to large wastewater treatment plants

● Facilities with higher flow rates and debris loads

● Operations requiring reduced labor costs

Advantages and Disadvantages

● Advantages:

○ Reduced labor requirements due to automation

○ Consistent performance with less downtime

● Disadvantages:

○ Higher initial cost compared to manual screens

○ Potential mechanical failures requiring maintenance

Cost Considerations and Operational Efficiency

While mechanical bar screens have a higher upfront cost, they often provide better long-term operational efficiency. The reduction in labor costs and improved reliability can lead to significant savings over time.

Definition and Functionality

Automatic bar screens are advanced systems that feature fully automated cleaning processes, often equipped with sensors and control systems for optimal operation. They continuously monitor performance and adjust cleaning cycles as needed.Key Differences from Mechanical Bar Screens

● Fully automated operation vs. semi-automated

● Enhanced monitoring and control capabilities

● Typically designed for high-flow applications

Benefits of Automation in Wastewater Treatment

● Improved Efficiency: Continuous operation without manual intervention ensures consistent performance.

● Reduced Labor Costs: Automation minimizes the need for personnel, allowing staff to focus on other critical tasks.

● Enhanced Reliability: Automated systems reduce the risk of human error and ensure timely debris removal.

Examples of Modern Automatic Bar Screen Systems

● Systems equipped with advanced sensors that detect debris levels

● Bar screens integrated with SCADA systems for remote monitoring

● Models that feature self-cleaning capabilities for reduced maintenance

Type of Bar Screen | Key Features | Suitable Applications |

Manual Bar Screen | Simple design, manual cleaning | Small facilities, low flow rates |

Mechanical Bar Screen | Automated cleaning, rake/scraper | Medium to large plants, higher flow |

Automatic Bar Screen | Fully automated, sensor-equipped | High-flow applications, remote monitoring |

Understanding the different types of bar screens helps facilities choose the right solution for their wastewater treatment needs, ensuring efficient operation and compliance with environmental standards.

Bar screens play a vital role in wastewater treatment, serving multiple essential functions that enhance operational efficiency and environmental protection. Their importance cannot be overstated, as they are key to maintaining the integrity of the entire treatment process.

One of the primary functions of a bar screen is to protect downstream equipment. By capturing large solids before they enter sensitive machinery, bar screens help prevent clogging and potential damage.

● Prevention of Equipment Failures: Clogged pumps and clarifiers can lead to costly repairs and downtime.

● Extended Equipment Lifespan: Keeping debris out of the system reduces wear and tear on pumps and valves, prolonging their operational life.

Bar screens significantly enhance the efficiency of the wastewater treatment process. By removing large solids, they ensure that the water entering subsequent treatment stages is as clean as possible.

● Improved Flow Rates: With fewer obstructions, water flows more smoothly through the treatment system.

● Greater Treatment Effectiveness: Clean water allows for better performance in biological and chemical treatment stages, leading to higher quality effluent.

Using bar screens can lead to lower maintenance requirements and reduced operational risks. This is particularly true for mechanical and automatic bar screens, which automate debris removal.

● Lower Labor Costs: Automated systems reduce the need for manual cleaning, allowing staff to focus on other critical tasks.

● Minimized Downtime: Regular maintenance is less frequent, which translates to fewer interruptions in treatment processes.

Bar screens play a crucial role in environmental protection. By preventing large debris from entering waterways, they help facilities comply with environmental regulations.

● Reduction of Pollution: By capturing materials like plastics and organic waste, bar screens reduce the risk of contamination in local water bodies.

● Support for Sustainable Practices: Facilities equipped with effective bar screens contribute to cleaner ecosystems and promote sustainable wastewater management practices.

Benefit of Bar Screens | Description |

Protection of Equipment | Prevents clogging and damage to pumps and valves |

Enhanced Treatment Efficiency | Improves flow rates and treatment effectiveness |

Reduced Maintenance Needs | Lowers labor costs and minimizes downtime |

Environmental Protection | Reduces pollution and supports sustainable practices |

Bar screens, whether manual, mechanical, or automatic, are indispensable in wastewater treatment. They protect equipment, enhance treatment efficiency, reduce maintenance needs, and contribute to environmental sustainability. Understanding their importance helps facilities optimize their operations and achieve compliance with regulations.

When designing a bar screen for wastewater treatment, several key considerations come into play. These factors ensure that the bar screen operates efficiently and effectively while meeting the specific needs of the facility.

Choosing the right material for a bar screen is critical for durability and performance. Common materials include:

● Stainless Steel: Highly resistant to corrosion, making it ideal for harsh wastewater environments. It offers longevity and requires minimal maintenance.

● Coated Carbon Steel: A more cost-effective option, coated carbon steel provides good resistance to corrosion and can be used in less aggressive environments.

● Other Materials: Depending on specific applications, materials like fiberglass or plastic may also be suitable, especially for lighter-duty applications.

The spacing between bars and the angle at which they are installed significantly influence the performance of a bar screen.

● Bar Spacing: The distance between bars should be optimized to capture the desired size of debris while allowing adequate flow. Typical spacing ranges from 0.5 to 2 inches, depending on the application.

● Installation Angle: An angle of 60 to 90 degrees is often recommended. This angle helps maximize debris capture while ensuring that water flows freely through the screen.

The cleaning mechanism is a vital component of both mechanical and automatic bar screens. Its design directly impacts maintenance efficiency.

● Mechanical Bar Screens: These often use rakes or brushes to remove debris. The design should allow for easy access for maintenance and repair.

● Automatic Bar Screens: Advanced systems feature automated cleaning mechanisms, such as rotating brushes or self-cleaning rakes. These systems minimize manual intervention and enhance operational efficiency.

Bar screens must be designed to withstand hydraulic pressure and the weight of accumulated debris.

● Structural Integrity: The frame and bars should be robust enough to handle the forces exerted by water flow and debris load. Proper engineering is essential to prevent bending or failure.

● Load Management: Calculating the expected load is crucial. Factors like peak flow rates and potential debris accumulation should be considered to ensure the bar screen can handle extreme conditions.

Design Consideration | Key Points |

Material Selection | Stainless steel for durability; coated carbon steel for cost-effectiveness |

Bar Spacing and Angle | Spacing of 0.5 to 2 inches; installation angle of 60 to 90 degrees |

Cleaning Mechanism Design | Rakes for mechanical screens; automated systems for efficiency |

Structural Integrity and Load | Robust design to withstand hydraulic pressure; load calculations are critical |

By carefully considering these design aspects, facilities can ensure their bar screens operate effectively, reducing maintenance needs and enhancing overall treatment efficiency. Whether opting for a mechanical or automatic bar screen, these factors play a pivotal role in achieving optimal performance.

Maintaining bar screens is crucial for ensuring their efficiency and longevity in wastewater treatment. Regular upkeep not only enhances performance but also minimizes operational disruptions.

Regular inspection and cleaning of bar screens are vital to their effective operation. Here’s why:

● Preventing Clogs: Accumulated debris can lead to clogs, which hinder water flow and reduce treatment efficiency.

● Extending Equipment Life: Consistent maintenance helps identify wear and tear early, allowing for timely repairs and prolonging the lifespan of the bar screen.

● Ensuring Compliance: Regular checks ensure that the system operates within regulatory standards, avoiding potential fines or penalties.

While maintaining bar screens is essential, several challenges can arise. Here are some common issues and their solutions:

● Debris Buildup: Heavy debris accumulation can obstruct flow.

○ Solution: Implement a routine cleaning schedule and consider using mechanical or automatic bar screens that incorporate self-cleaning mechanisms.

● Wear and Tear: Over time, components can degrade, leading to reduced efficiency.

○ Solution: Use high-quality materials for construction, such as stainless steel, to enhance durability.

● Access Issues: Manual cleaning can be difficult in tight spaces.

○ Solution: Design bar screens with access points for easier maintenance, or invest in automatic systems that reduce manual intervention.

Automated cleaning systems offer significant advantages in the maintenance of bar screens:

● Labor Reduction: Automatic bar screens require less manual cleaning, freeing up staff for other important tasks.

● Consistent Performance: These systems maintain optimal operation by regularly removing debris without human intervention.

● Increased Efficiency: Automation minimizes downtime related to maintenance, ensuring that the treatment process remains uninterrupted.

Safety is paramount during maintenance operations. Implementing the following measures can help protect workers:

● Personal Protective Equipment (PPE): Always ensure that maintenance staff wear appropriate PPE, such as gloves, goggles, and hard hats.

● Lockout/Tagout Procedures: Before performing maintenance, ensure that all machinery is properly shut down and locked out to prevent accidental start-up.

● Training and Awareness: Regular training sessions can help staff recognize hazards and understand safe practices when working on bar screens.

Maintenance Aspect | Key Considerations |

Regular Inspection and Cleaning | Prevent clogs, extend equipment life |

Common Challenges | Debris buildup, wear and tear, access issues |

Automated Cleaning Benefits | Labor reduction, consistent performance |

Safety Measures | PPE, lockout/tagout procedures, training |

By focusing on these maintenance strategies, facilities can ensure their bar screens operate effectively, contributing to the overall success of wastewater treatment processes. Whether using mechanical or automatic bar screens, proper maintenance is essential for optimal performance.

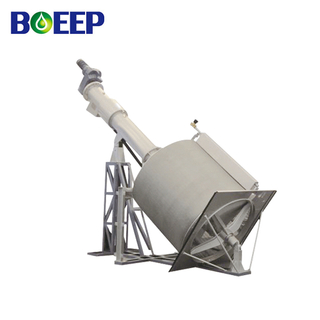

Bar screens play a critical role in wastewater treatment. They protect equipment, enhance efficiency, and reduce maintenance needs. Choosing the right bar screen is essential for optimal performance in any facility. For expert advice on selection and maintenance, consider reaching out to BOEEP. Their products offer unique advantages that add value to your wastewater management solutions. Visit BOEEP to learn more about their offerings and how they can support your needs.

A: A bar screen is a device used to remove large debris from wastewater, protecting downstream equipment.

A: A mechanical bar screen uses automated rakes to remove debris, enhancing efficiency in wastewater treatment.

A: An automatic bar screen reduces labor costs by automating the cleaning process, ensuring consistent operation.

A: Bar screens improve treatment efficiency, prevent equipment damage, and reduce maintenance needs.

A: Consider factors like flow rate, debris type, and whether a mechanical or automatic bar screen best suits your needs.