| Availability: | |

|---|---|

| Quantity: | |

MYDN303

BOEEP

MYDN

Product Description

The BOEEP Inclined Screw Thickener offers a significant upgrade over conventional volute screw press dewatering systems, providing low operating and maintenance costs, high dewatering efficiency, odor suppression, and quiet operation. It is specifically designed to handle low-concentration sludge (ranging from 2,500 mg/L to 20,000 mg/L) from secondary sedimentation tanks, enabling fast and continuous thickening. The system can consistently raise sludge solids to a stable 90%–96% concentration without requiring a separate thickening tank, making it a compact and cost-effective option. Moreover, the Inclined Screw Thickener reduces odor and phosphorus emissions, streamlines downstream processing, and improves the overall performance of sludge dewatering and drying operations.

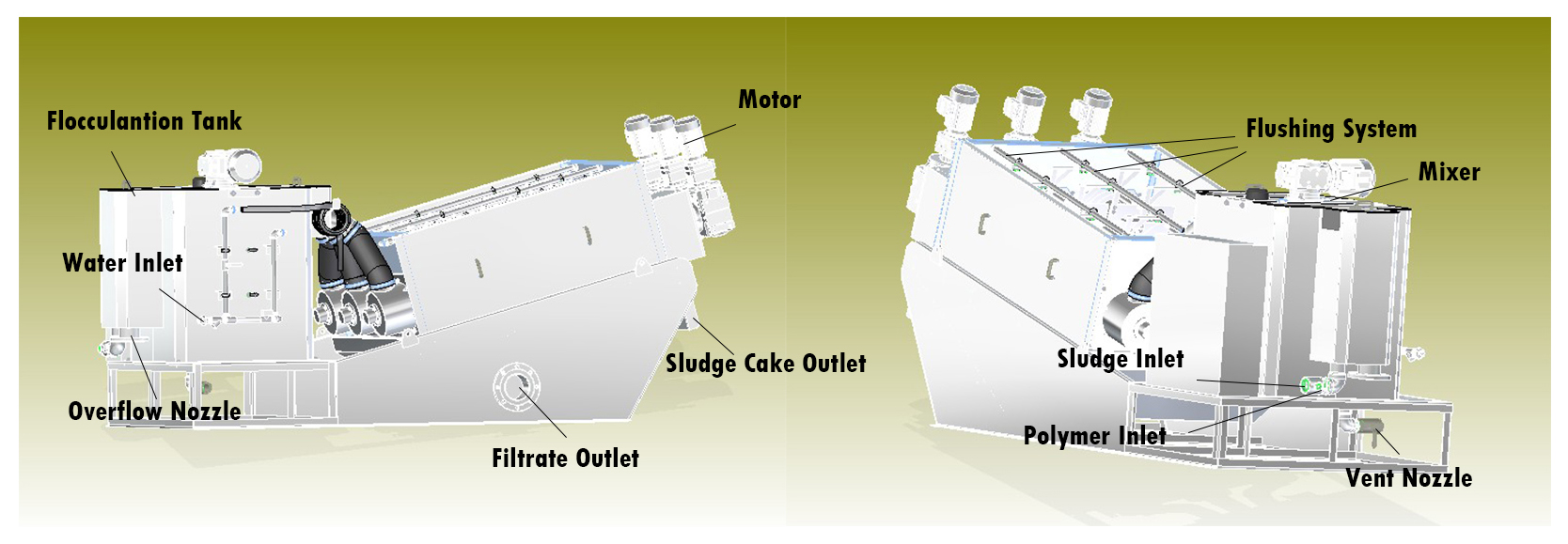

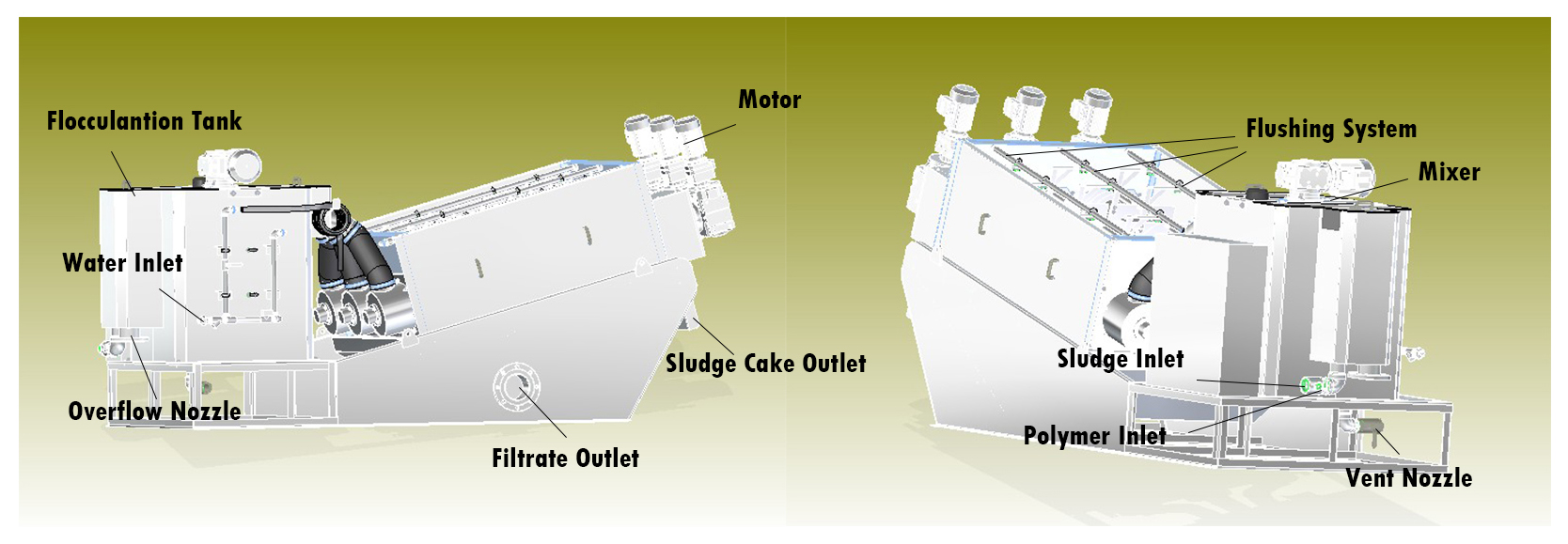

Main Structure & Working Principle

The BOEEP Inclined Screw Sludge Thickener consists of the screw assembly, drive unit, filtrate collection tank, mixing system, and support frame. The main structure of the volute screw press thickener is formed by three key components: the fixed ring, the movable ring, and the screw shaft that runs through the entire assembly.

The BOEEP Inclined Screw Sludge Thickener is primarily composed of a concentrating unit, drive system, filtrate tank, mixing section, and supporting frame. During operation, sludge is delivered into the mixing chamber via the sludge pump, while the dosing pump adds a controlled amount of prepared polymer. The mixing motor thoroughly blends the sludge and polymer, forming flocs. Once the liquid reaches the high-level sensor, the screw assembly begins operating, pressing the sludge. The thickened sludge is gradually discharged from the outlet, while the filtrate is separated and flows out through the gaps between the fixed and movable rings.

In essence, the inclined screw thickener utilizes the principle of screw extrusion, where the combination of high pressure generated by changes in screw pitch and the narrow gap between the fixed and movable rings effectively concentrates the sludge.

Application

1-Solid and liquid separation in the municipla & industrial wastewater treatment system.

2-Sludge dewatering in the municipal & industrial wastewater treatment system.

3-Instead of condensed tank, work as the pre-treat device of the sludge dewatering system.

4-It is the pre-treat device of sludge deep dewatering, also as the auxiliary equipment of high pressure plate and frame filter press, membrane filter presser.

5-Other wastewater treatment applications in the municipal & industrial wastewater treatment system.

Adavantages

Suitable for a wide sludge concentration range (water content: 98%-99.8%)

High concentration efficiency with minimal space requirements

Low-speed operation reduces noise, power consumption, and wear

Adjustable sludge water content (90%-96%) post-thickening

Self-cleaning, clog-free system with no need for filter cloth or high-pressure rinsing

Enclosed design controls odor emissions

Fully automated system reduces labor demands and operational complexity

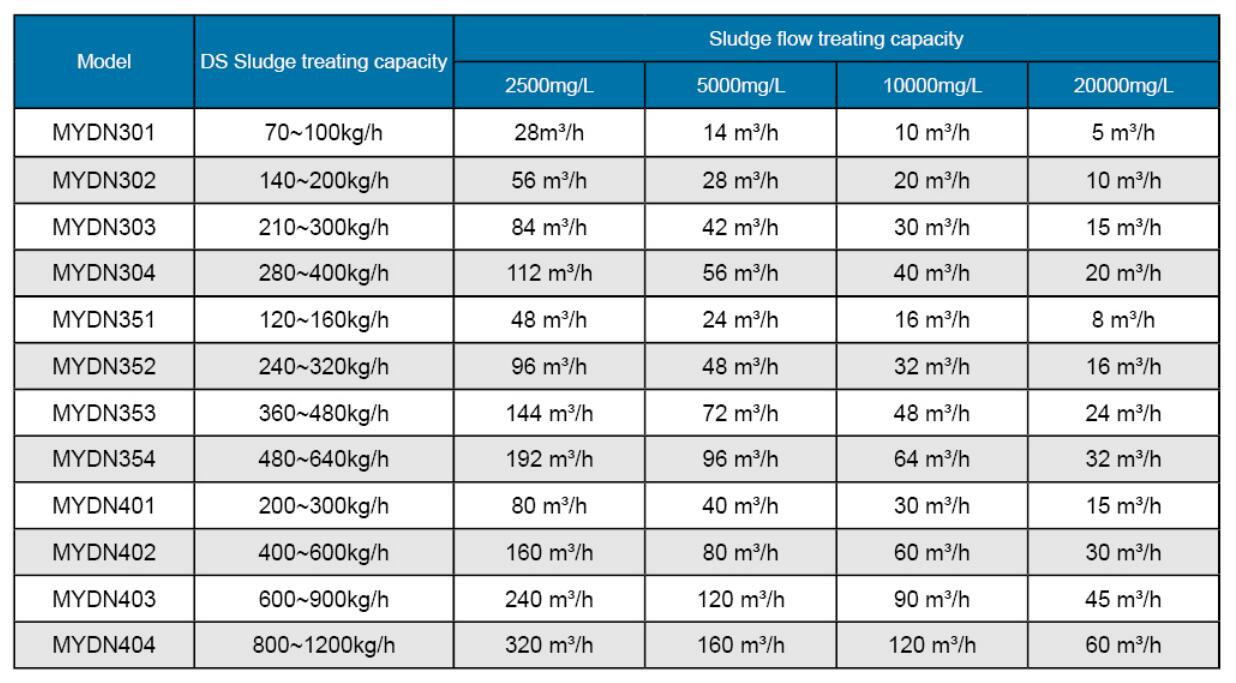

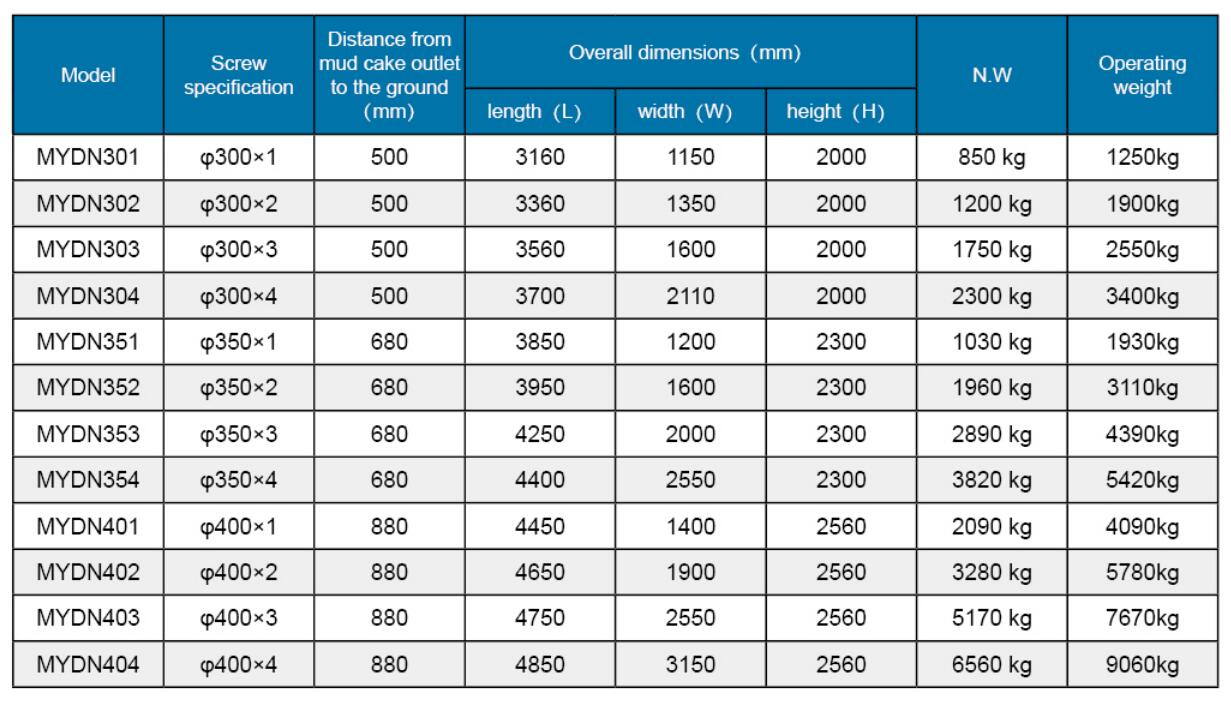

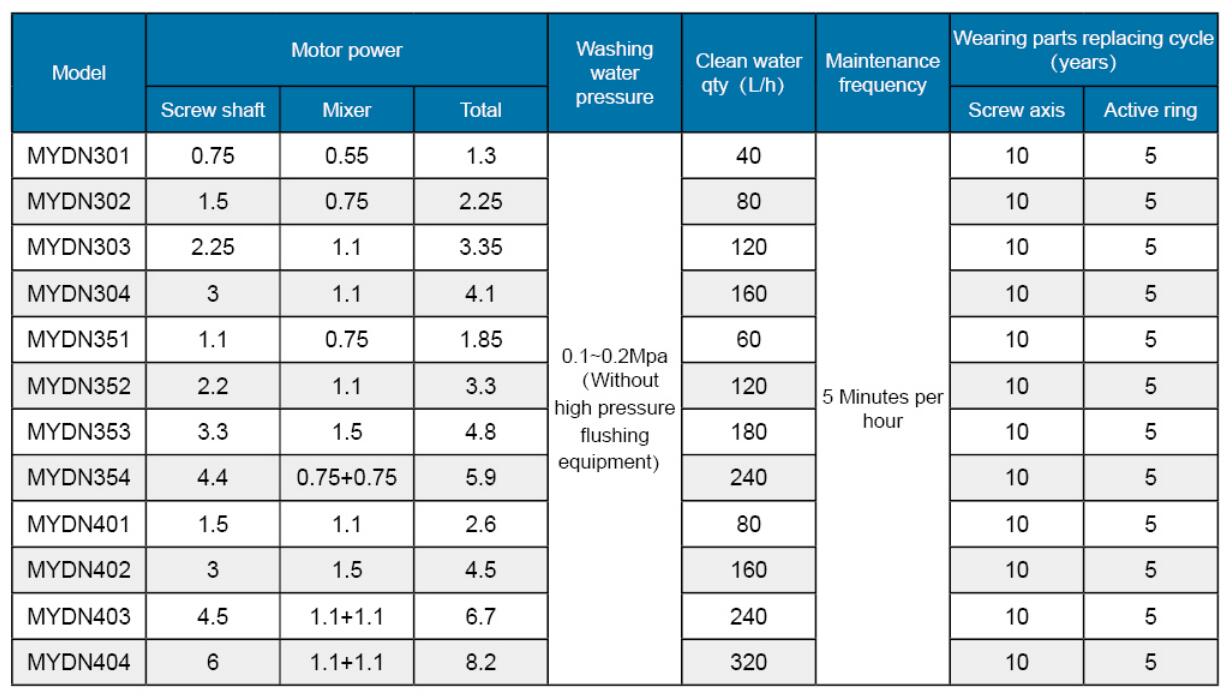

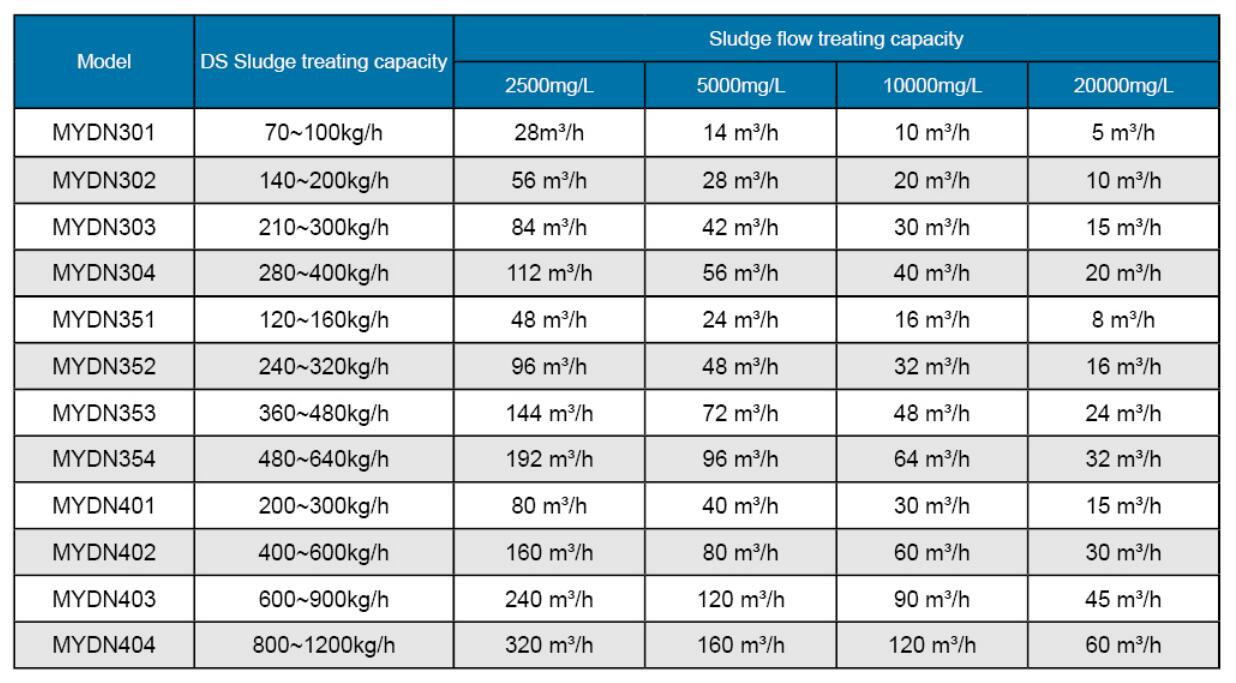

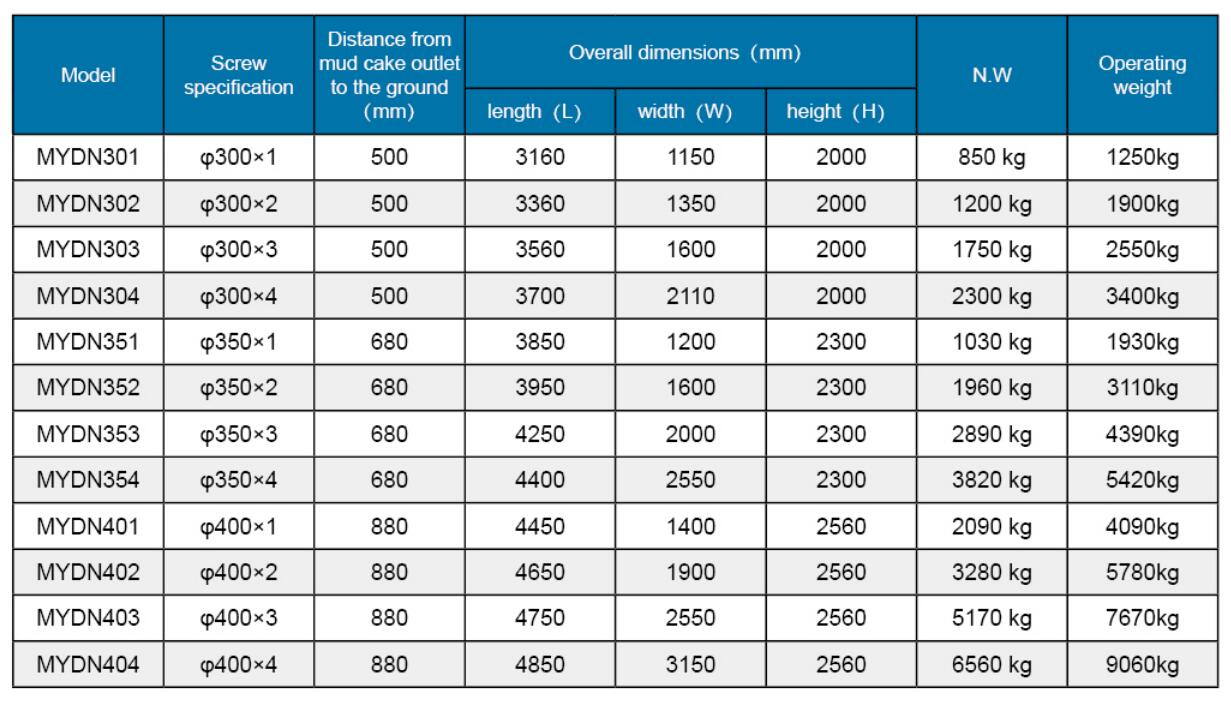

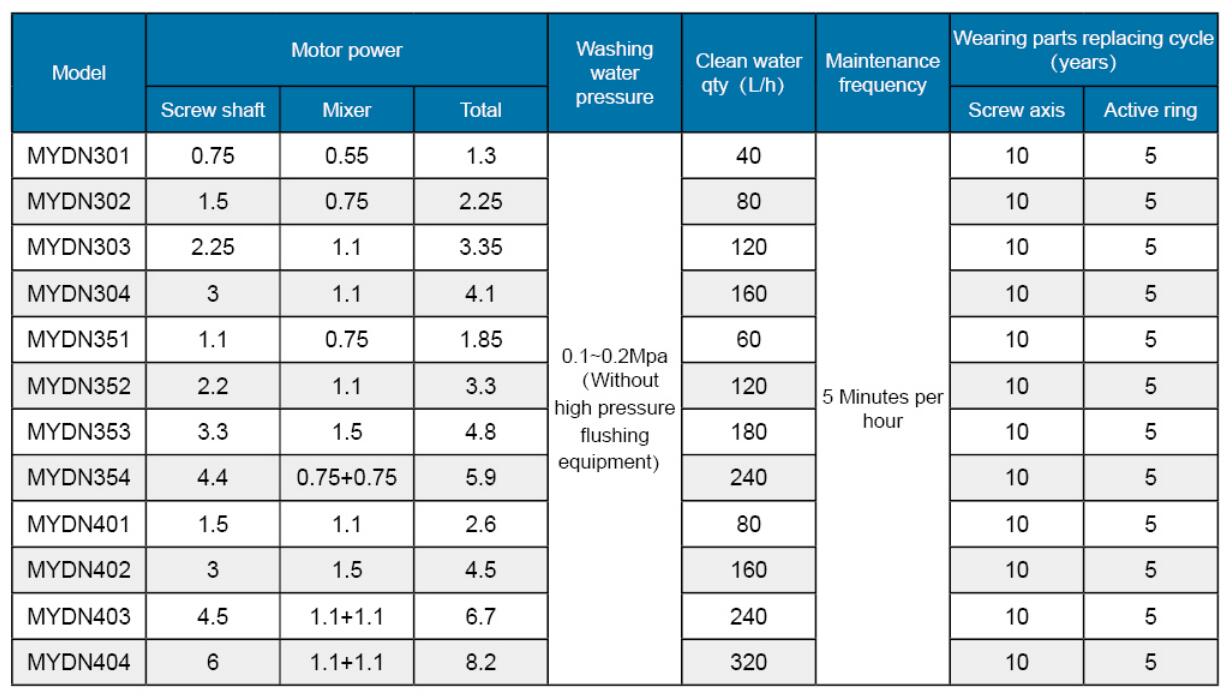

Technical Parameters

| Parameter | |

| Type:MYDN303 | Dimension:L3535×W1620×H1720(mm) |

| Inlet sludge solid concentration:2500~20000mg/L | Capacity:210-300kgds/h |

| Power:3.35kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Outlet sludge moisture content:90-95% |

| Polymer feeding rate:DS 0.2~1% | Flush water:120L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:1750kg |

| Screw body | Flocculation mixing tank |

| Diameter × Length:Φ300×2110(mm) | Dimension:L850×W850×H1000(mm) |

| Quantity:3pcs | Volume:about 650L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:0.75×3kW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls thickening body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Technical Specification

Packing Site

Product Description

The BOEEP Inclined Screw Thickener offers a significant upgrade over conventional volute screw press dewatering systems, providing low operating and maintenance costs, high dewatering efficiency, odor suppression, and quiet operation. It is specifically designed to handle low-concentration sludge (ranging from 2,500 mg/L to 20,000 mg/L) from secondary sedimentation tanks, enabling fast and continuous thickening. The system can consistently raise sludge solids to a stable 90%–96% concentration without requiring a separate thickening tank, making it a compact and cost-effective option. Moreover, the Inclined Screw Thickener reduces odor and phosphorus emissions, streamlines downstream processing, and improves the overall performance of sludge dewatering and drying operations.

Main Structure & Working Principle

The BOEEP Inclined Screw Sludge Thickener consists of the screw assembly, drive unit, filtrate collection tank, mixing system, and support frame. The main structure of the volute screw press thickener is formed by three key components: the fixed ring, the movable ring, and the screw shaft that runs through the entire assembly.

The BOEEP Inclined Screw Sludge Thickener is primarily composed of a concentrating unit, drive system, filtrate tank, mixing section, and supporting frame. During operation, sludge is delivered into the mixing chamber via the sludge pump, while the dosing pump adds a controlled amount of prepared polymer. The mixing motor thoroughly blends the sludge and polymer, forming flocs. Once the liquid reaches the high-level sensor, the screw assembly begins operating, pressing the sludge. The thickened sludge is gradually discharged from the outlet, while the filtrate is separated and flows out through the gaps between the fixed and movable rings.

In essence, the inclined screw thickener utilizes the principle of screw extrusion, where the combination of high pressure generated by changes in screw pitch and the narrow gap between the fixed and movable rings effectively concentrates the sludge.

Application

1-Solid and liquid separation in the municipla & industrial wastewater treatment system.

2-Sludge dewatering in the municipal & industrial wastewater treatment system.

3-Instead of condensed tank, work as the pre-treat device of the sludge dewatering system.

4-It is the pre-treat device of sludge deep dewatering, also as the auxiliary equipment of high pressure plate and frame filter press, membrane filter presser.

5-Other wastewater treatment applications in the municipal & industrial wastewater treatment system.

Adavantages

Suitable for a wide sludge concentration range (water content: 98%-99.8%)

High concentration efficiency with minimal space requirements

Low-speed operation reduces noise, power consumption, and wear

Adjustable sludge water content (90%-96%) post-thickening

Self-cleaning, clog-free system with no need for filter cloth or high-pressure rinsing

Enclosed design controls odor emissions

Fully automated system reduces labor demands and operational complexity

Technical Parameters

| Parameter | |

| Type:MYDN303 | Dimension:L3535×W1620×H1720(mm) |

| Inlet sludge solid concentration:2500~20000mg/L | Capacity:210-300kgds/h |

| Power:3.35kw | Protection Level:IP55 F |

| Power Supply:380V/3/50Hz | Outlet sludge moisture content:90-95% |

| Polymer feeding rate:DS 0.2~1% | Flush water:120L/h |

| Water supply pressure:≥0.2MPa | Equipment weight:1750kg |

| Screw body | Flocculation mixing tank |

| Diameter × Length:Φ300×2110(mm) | Dimension:L850×W850×H1000(mm) |

| Quantity:3pcs | Volume:about 650L |

| Material:Plate: SUS304/ Screw Shaft: SUS304 | Material:SS304 |

| Motor Power:0.75×3kW | Motor power:1.1kw |

| Electrical Cabinet | |

| 1. Frequency converting controls thickening body; | |

| 2. Controls polymer mixing device; | |

| 3. Realize the switch of automatic operation and manual operation. | |

Technical Specification

Packing Site